Filter housing made of plastic and filter system

A filter system and filter technology, applied in the direction of membrane filter, charging system, cartridge filter, etc., can solve the problem of expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

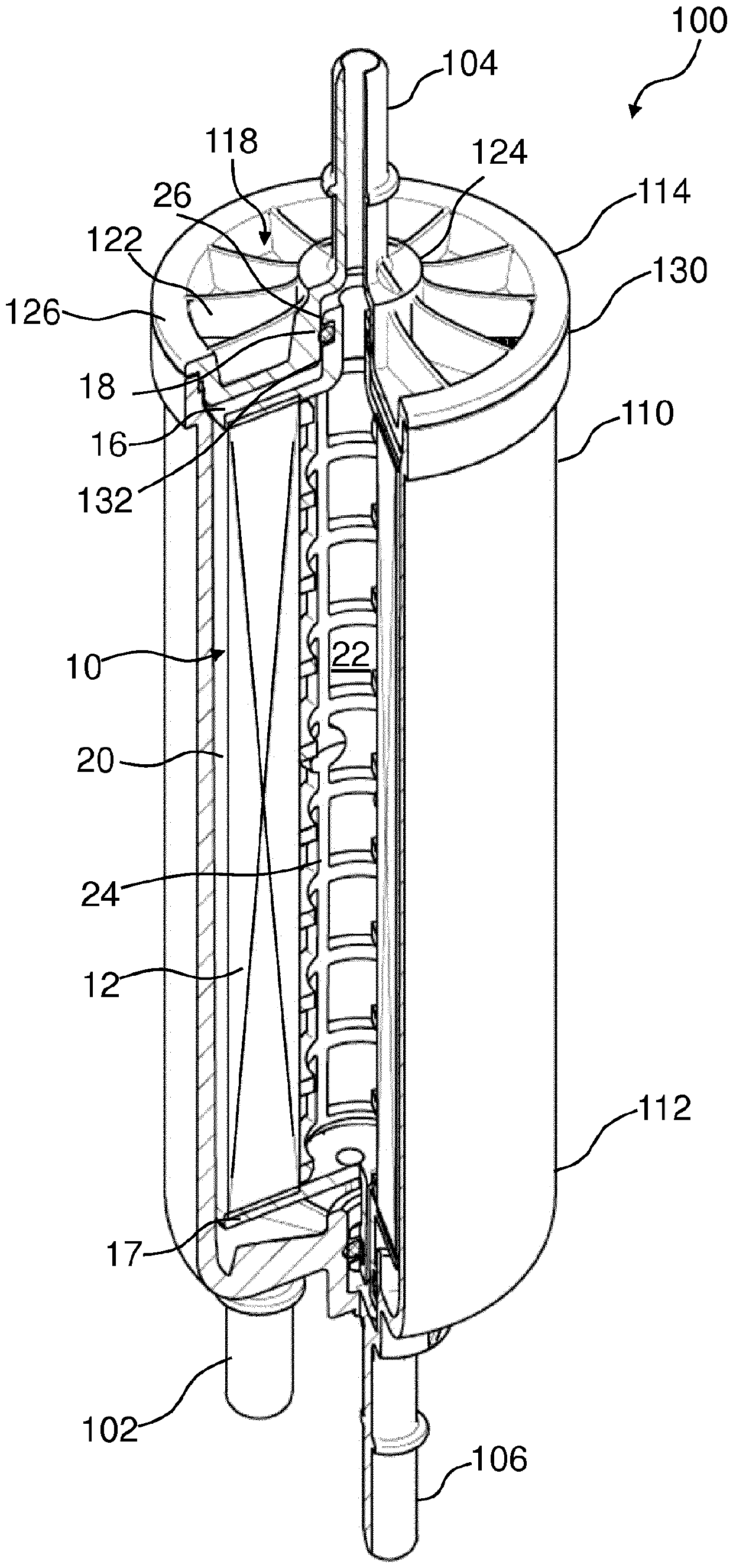

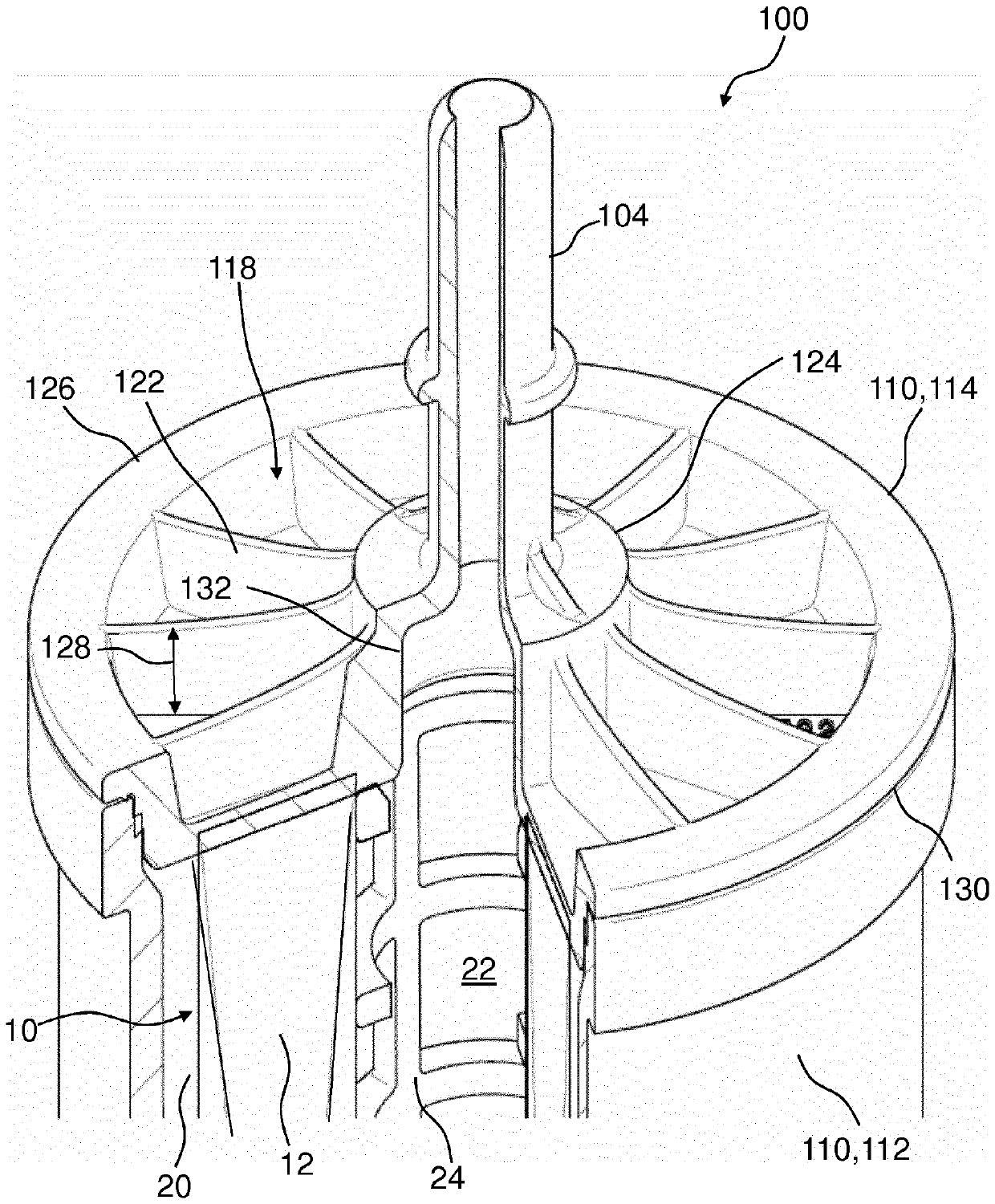

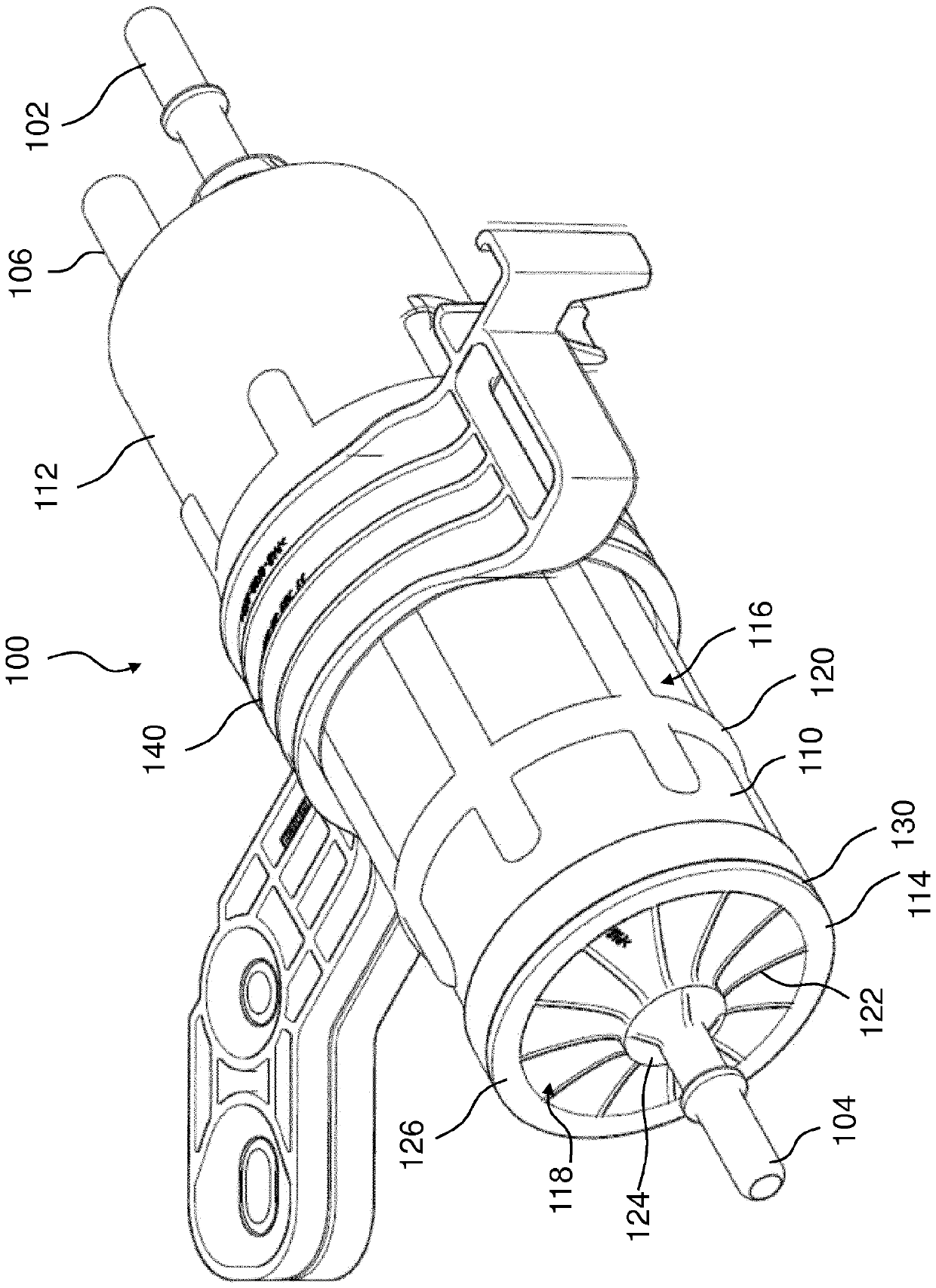

[0047] Identical or similar components are numbered with the same reference symbols in the figures. The figures show only embodiments and should not be interpreted as restrictive.

[0048] figure 1 A filter housing 110 according to an exemplary embodiment of the invention is shown in an isometric view. The filter housing 110 , preferably made of plastic, is provided as part of a filter system 100 for fuel filtration with an internal filter element and has a first housing part 112 in the form of a housing pot. and a second housing part 114 as a housing cover. The two housing parts 112 , 114 can be joined together at the outer edge 126 of the second housing part 114 and can be welded together at the connecting seam 130 , for example, in particular by ultrasonic welding. As an alternative, bonding of the two housing parts 112 , 114 is also conceivable.

[0049] Filter housing 110 has at least one inlet 102 and outlet 104 for fluid, in particular fuel. Outlet 104 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com