Experimental decoupling device to realize physical separation of centrifugal fan excitation characteristics

A centrifugal fan, physical separation technology, applied in mechanical equipment, machine/engine, pump control, etc., can solve the problems of inability to reduce vibration and noise, difficulty in quantitative identification of excitation sources, inability to separate excitation sources, etc., to reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

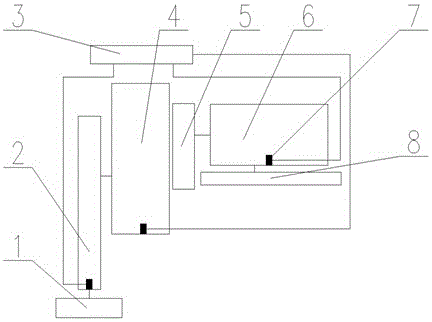

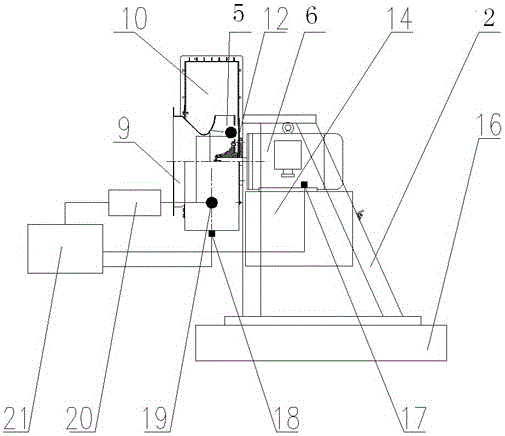

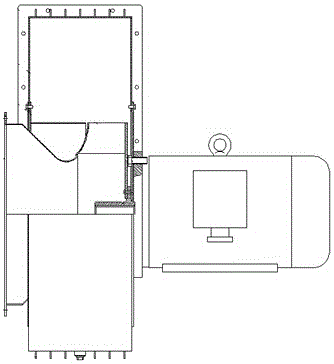

[0027] Such as figure 1 As shown, a test decoupling device for realizing the physical separation of centrifugal fan excitation characteristics is mainly composed of a decoupling system, a support system, a fan system, a drive system, and a test system.

[0028] The decoupling system is composed of a separate decoupling bracket 2 specially designed for centrifugal fans; the support system is composed of a decoupling system support base 1 and a drive system support base 8. The two support bases are independent of each other and can be rigid support or elastic according to the purpose of the test. Support; fan system 4 is composed of centrifugal fan related components and impeller 5; drive system is composed of drive motor 6, the speed of which is adjustable; test system is composed of signal acquisition and data analysis device 3 and sensor 7. The fan s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com