Method for calculating positions to synchronise a dual clutch gearbox

A calculation method, double-clutch technology, applied to elements with teeth, transmission control, belt/chain/gear, etc., can solve problems such as deterioration of comfort and wear, inaccurate control of synchronous sleeves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

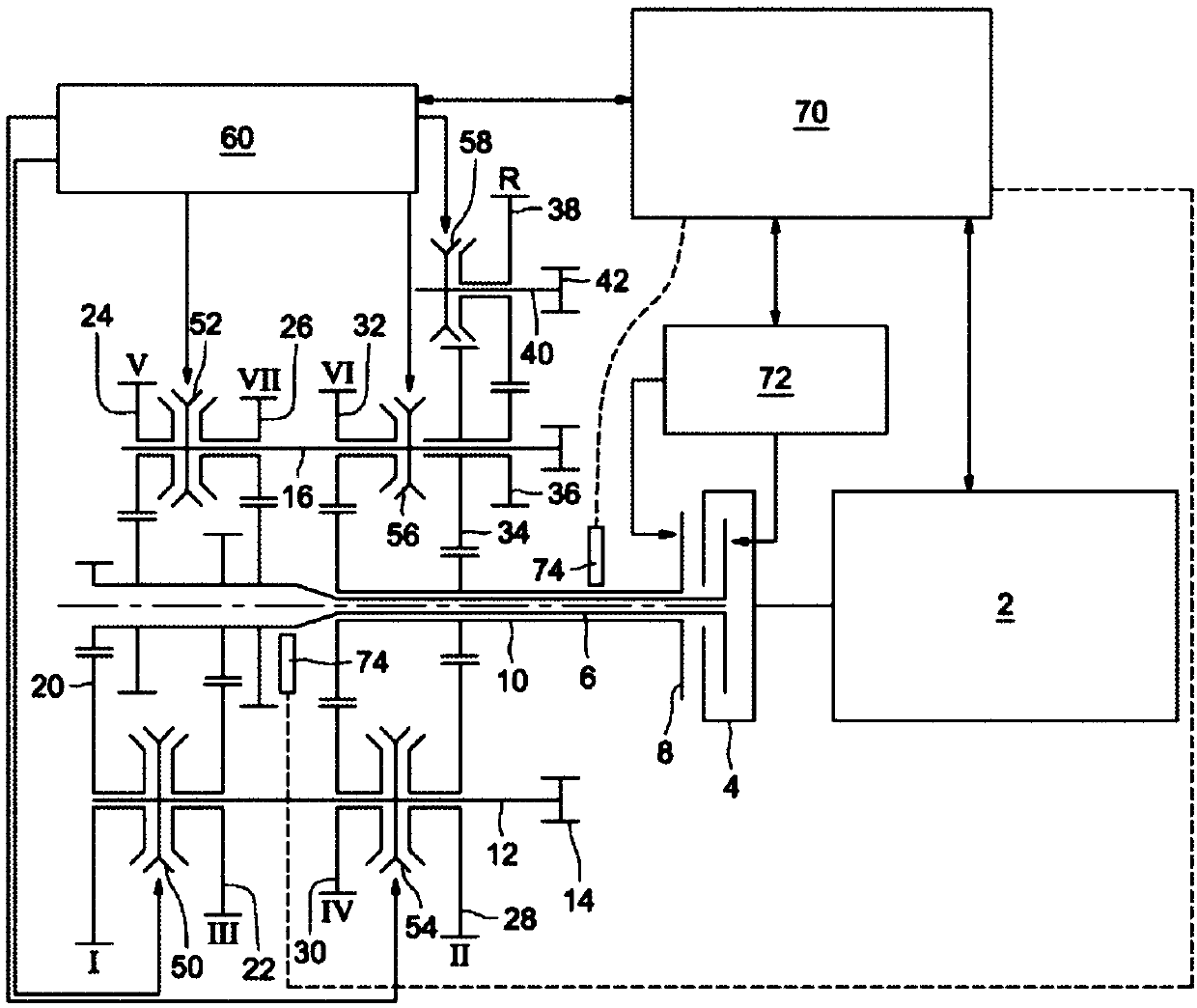

[0041] figure 1 Shown is a powertrain comprising a heat engine 2 driving a dual clutch gearbox comprising a first input clutch 4 driving a first main shaft 6 and a second input clutch 8 driving a second main shaft 10, the second The spindle is hollow and receives the first spindle internally.

[0042] The gearbox includes a first layshaft 12 having an output gear 14 , a second layshaft 16 having an output gear 18 and a third layshaft 40 having an output gear 42 . Various output gears 14 , 18 , 42 mesh on ring gears of a differential not shown in order to distribute the movement to the drive wheels.

[0043] To form a first half box comprising odd ratios, the first countershaft 12 receives the movement of the first main shaft 6 through a first gear pair 20 to form a first transmission ratio I and through a third gear pair 22 receives the movement of the first main shaft to form the third transmission ratio III. The second countershaft 16 receives the movement of the first ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com