A kind of automatic door body foaming equipment and using method

A technology of foaming equipment and automatic doors, which is applied in the field of special equipment for mechanical processing, can solve the problems of increasing production costs, occupying the location of the workshop, and uneven foaming, and achieves the advantages of saving floor space, reducing handling, and uniform foaming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

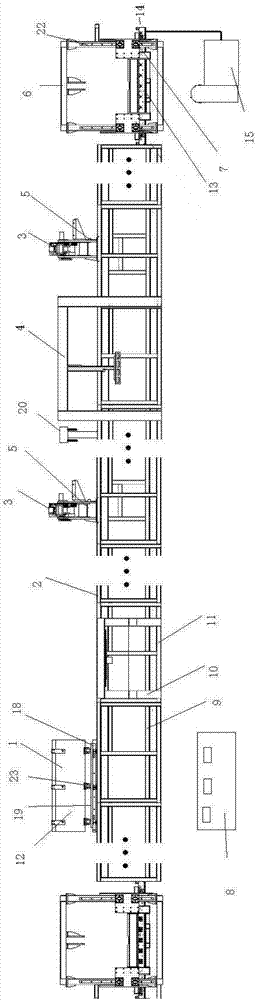

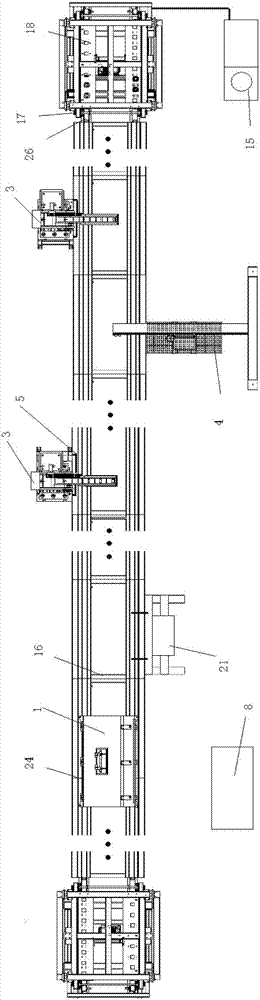

[0033] An automatic door body foaming equipment, including a frame, a lifter 6, a mold car 1, a transmission mechanism, an open-type injection manipulator 20, a closed-type injection manipulator 21, an opening and closing lock manipulator 5, an opening and closing mold manipulator 3, a take-off The door manipulator 4 and the control cabinet 8 are welded by the frame including a beam 9, a longitudinal beam 16 and a leg 10, and also includes a panel 2 and a bottom plate 11, forming an upper and lower two-layer structure.

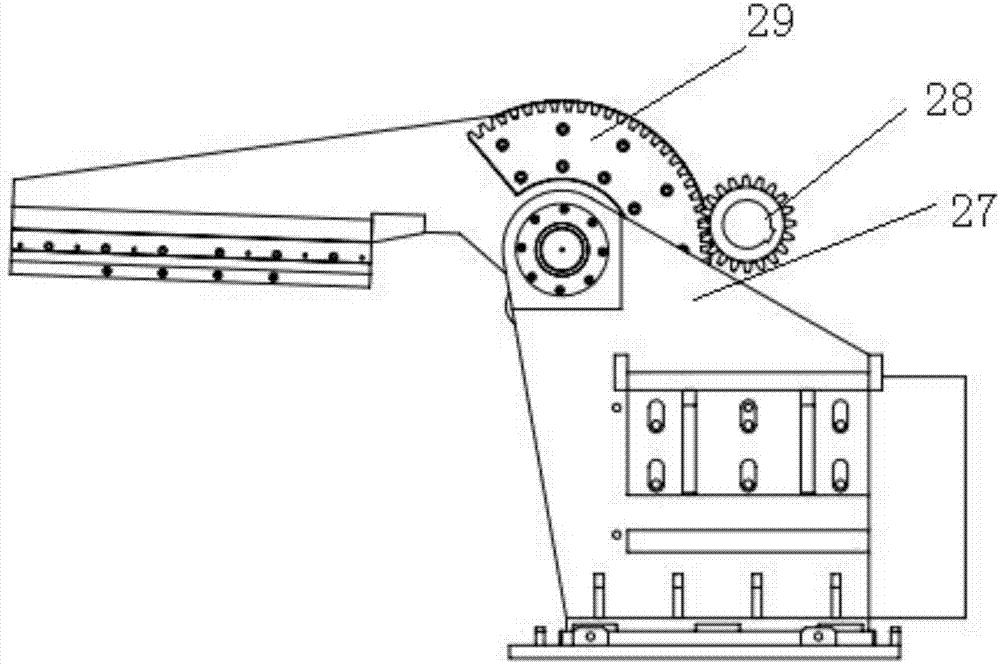

[0034] The elevator 6 includes a roller transmission line composed of a gear 7 connected by a rack 22 , a hydraulic cylinder 14 , a lifting frame 13 and a roller 18 , and the hydraulic cylinder 14 is connected to a power hydraulic station 15 . Die car 1 is on the frame, and elevator 6 is at the two ends of frame.

[0035] Described mold car 1 is connected loam cake 12 and formwork 18 by the hinge 23 of opening and closing, and mold 19 is arranged inside descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com