System for monitoring leaks of liquid from a spent fuel pool

A spent nuclear fuel and monitoring system technology, applied in the field of nuclear power plant storage tank leakage monitoring, can solve the problems of metal inner bottom, increase storage tank maintenance time, metal inner bottom, etc., and achieve the effect of increasing safety and shortening maintenance time of the pool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

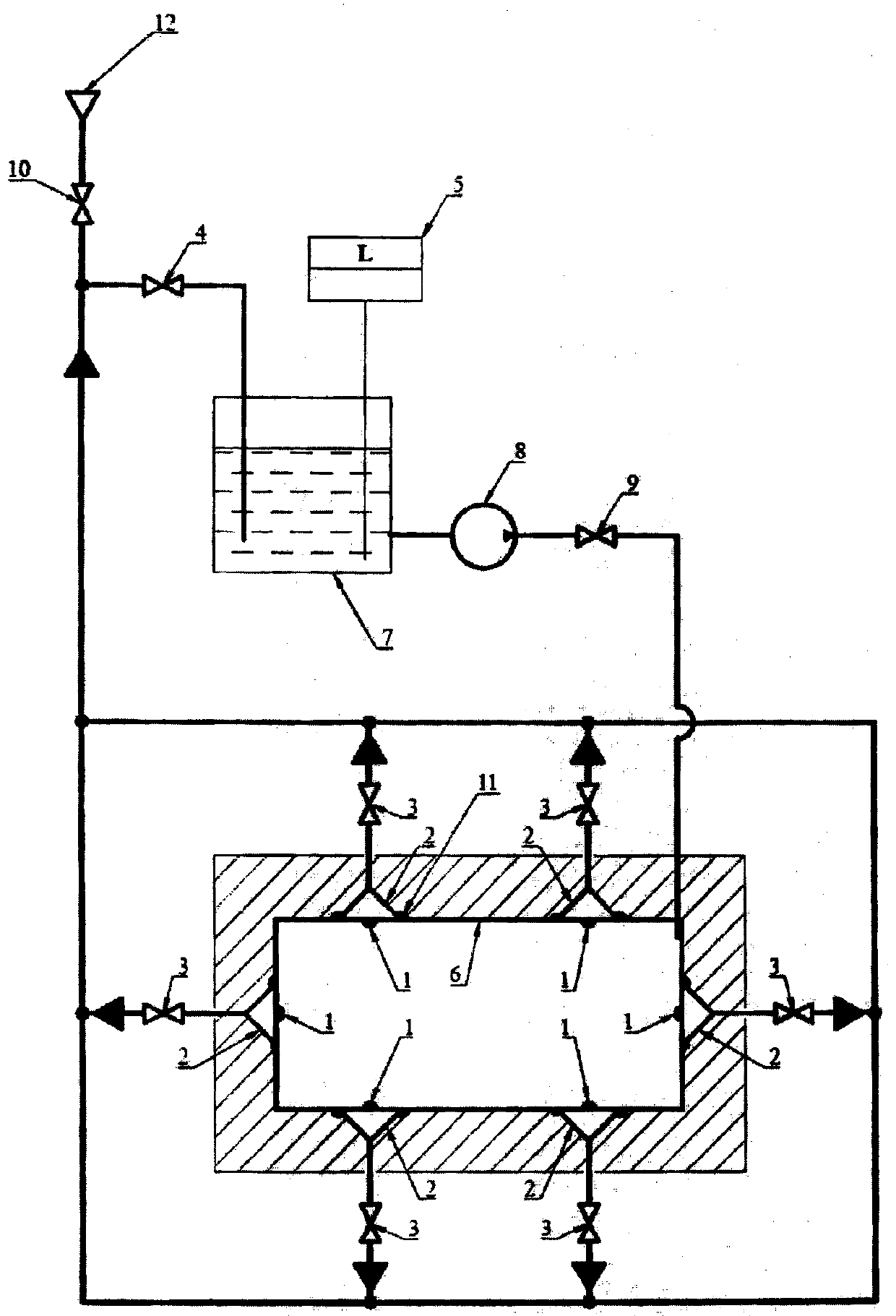

[0022] The spent nuclear fuel storage pool leak detection system operates as follows. When the spent nuclear fuel is stored in the storage pool 6, the operator, with the help of the control unit, periodically opens the valves 3 one by one while the other valves 3 are closed, and also checks the level control with the check valve 9 and the pump 8 closed The scale of sensor 5. At the same time, if the indication of the liquid level control sensor 5 remains unchanged, the operator concludes that the welding seam 1 opposite to the open valve 3 has no leakage. If the liquid level control sensor 5 indicates an increase in the liquid level in the leakage collection tank 7, the operator concludes that there is a leak in the weld seam 1 opposite to the open valve 3. Thereafter, the operator likewise inspects the remaining welds. After checking or filling the leak collection tank 7, the operator uses the pump 8 to flow the leaked water back into the storage tank while the check valve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap