Grass trimmers

A lawn mower and mowing head technology, applied in the field of lawn mowers, can solve the problems of single-side winding, interruption of the winding process, user fatigue, etc., and achieve the effect of improving reliability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

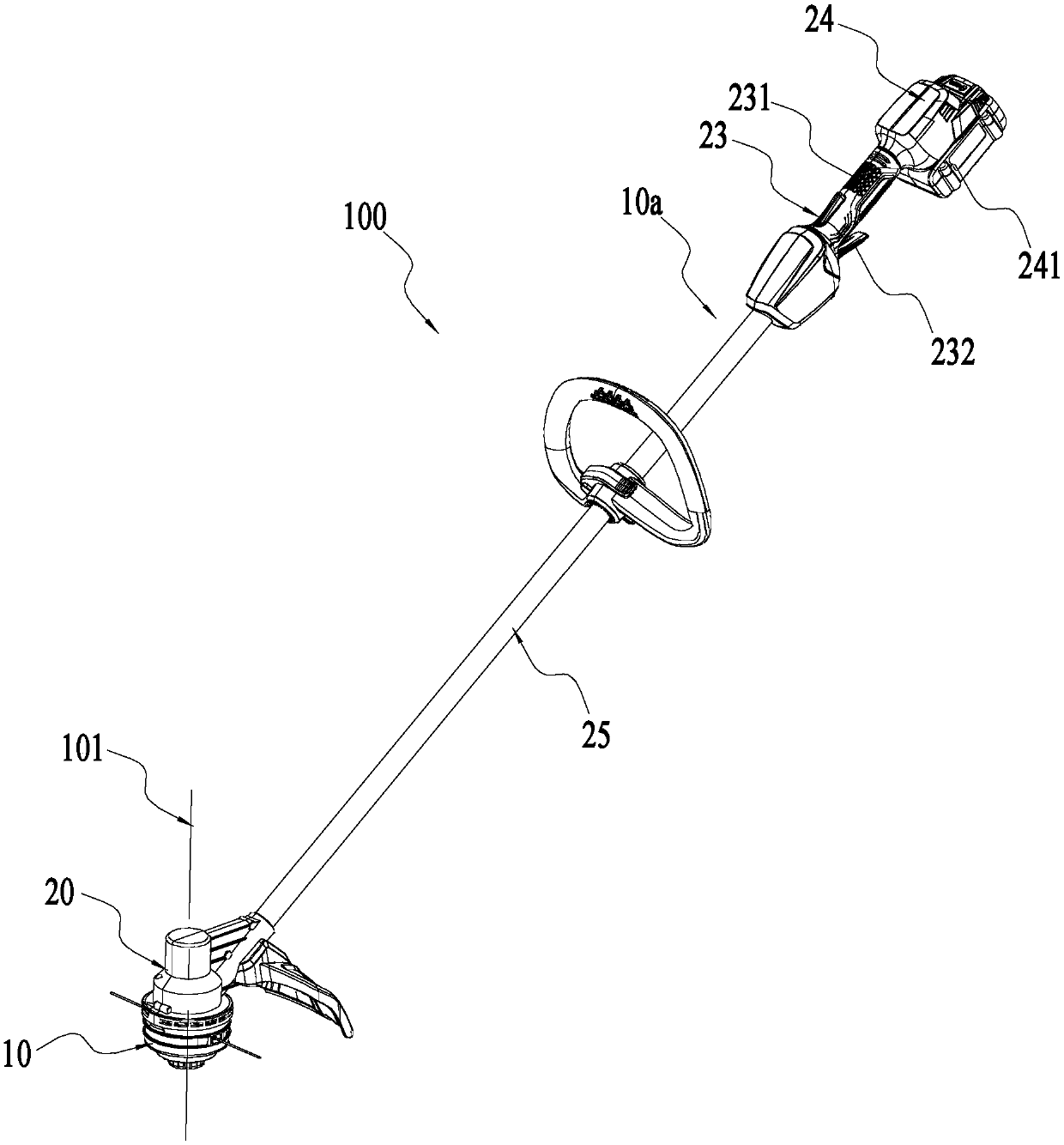

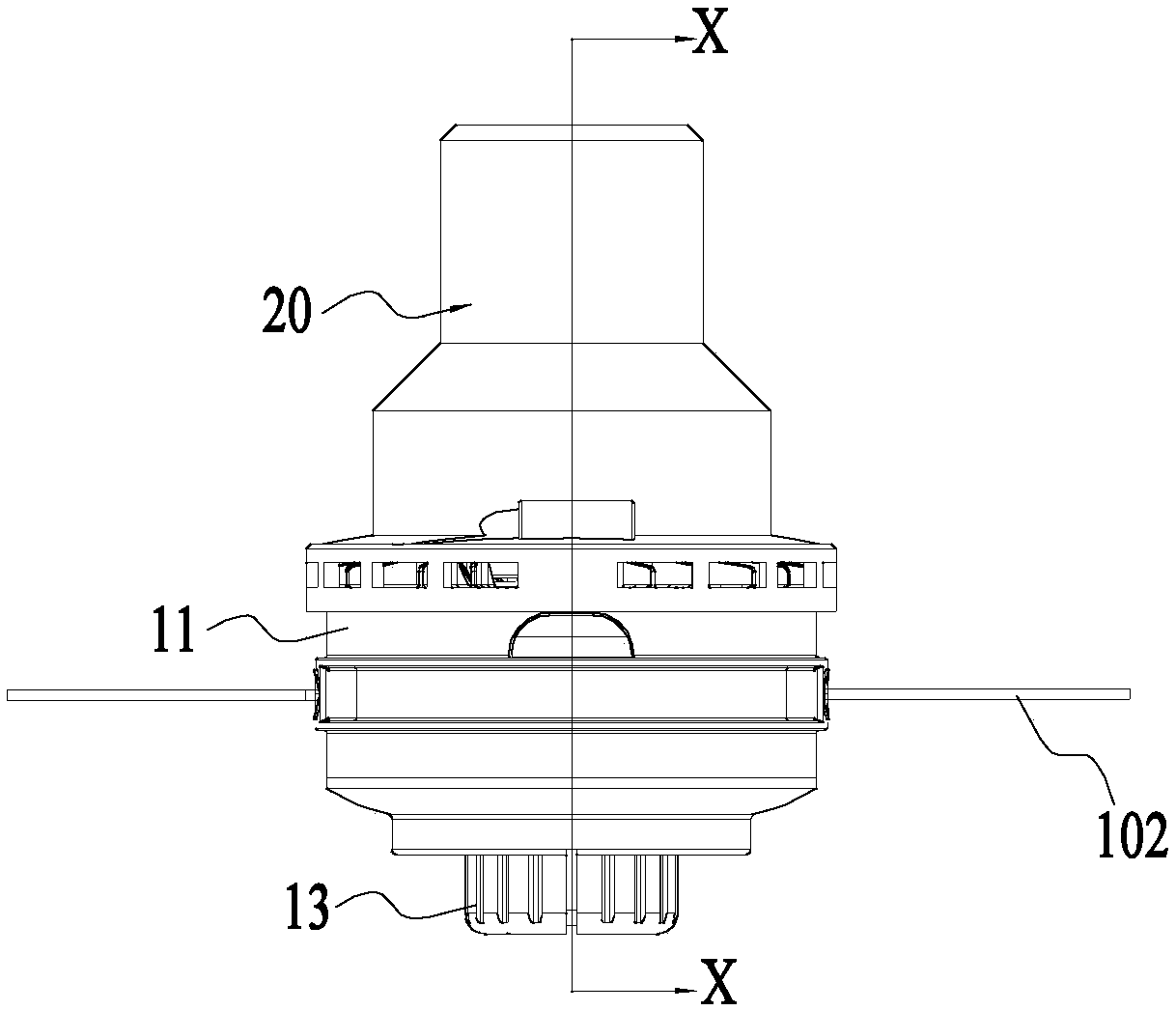

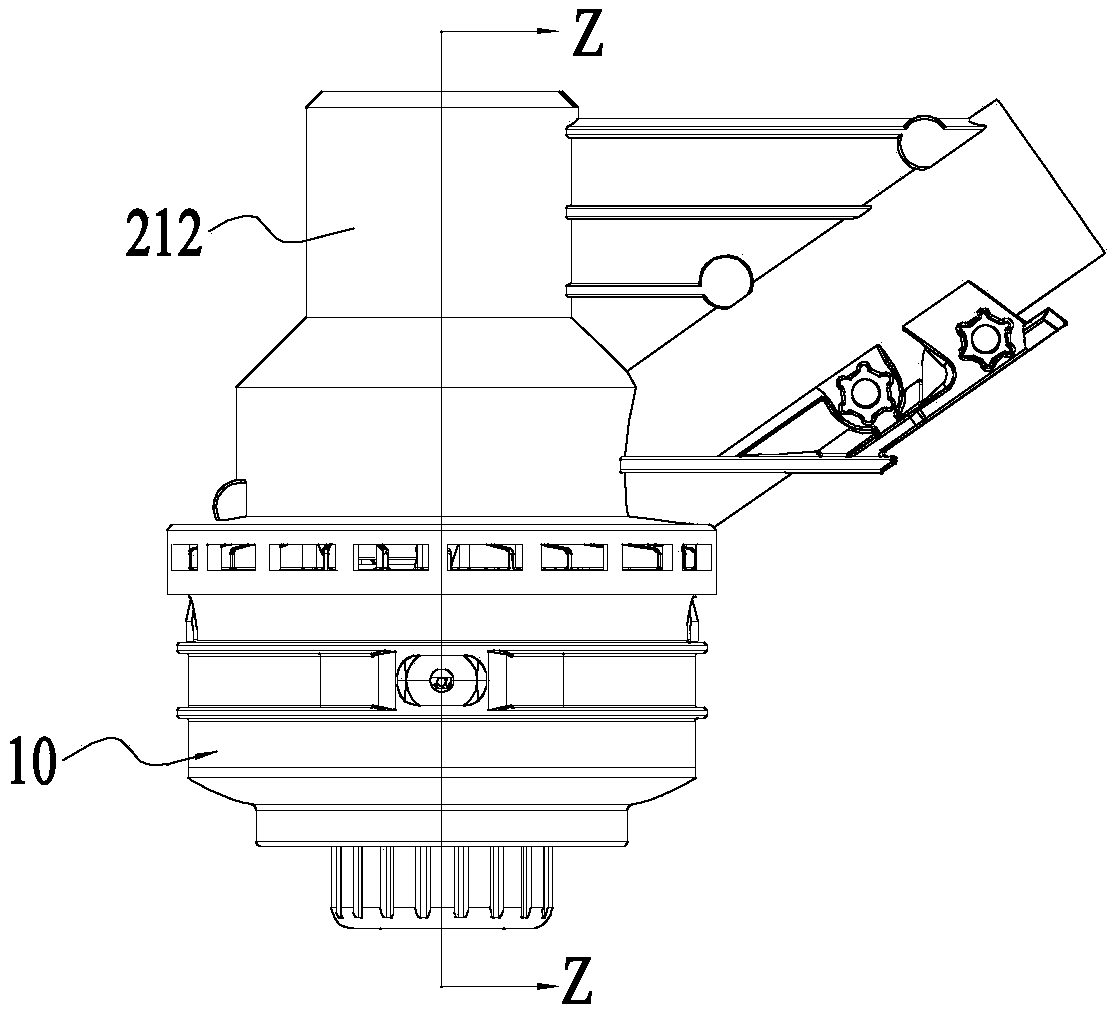

[0055] figure 1 The shown lawnmower 100 installed with the mowing head 10 is used as a lawn trimming tool for the user to mow grass or trim vegetation or trim the lawn. like figure 1 As shown, the mowing machine 100 includes: a mowing head 10 and a mowing host 10 a, and the mowing host 10 a includes: a driving device 20 , an operating device 23 , a power supply device 24 and a connecting device 25 . Wherein, the operating device 23 may include a handle 231 for the user to hold, and may also include a main switch 232 for starting the mower 100 to mow grass. The power supply device 24 may include a battery pack 241 for supplying electric power.

[0056] The mowing head 10 is used for mowing grass, the driving device 20 is used to drive the mowing head 10 to rotate around the axis of rotation 101, the operating device 23 is used for the user to operate to control the mowing machine 100, and the power supply device 24 is used to power the driving device. 20 provides a power sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com