Transition tank

A technology of tank body and filter screen, applied in the field of transition tanks, can solve the problems of low gas phase purity and mixed gas phase, etc., and achieve the effect of promoting condensation and collection, ensuring purity, and improving purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

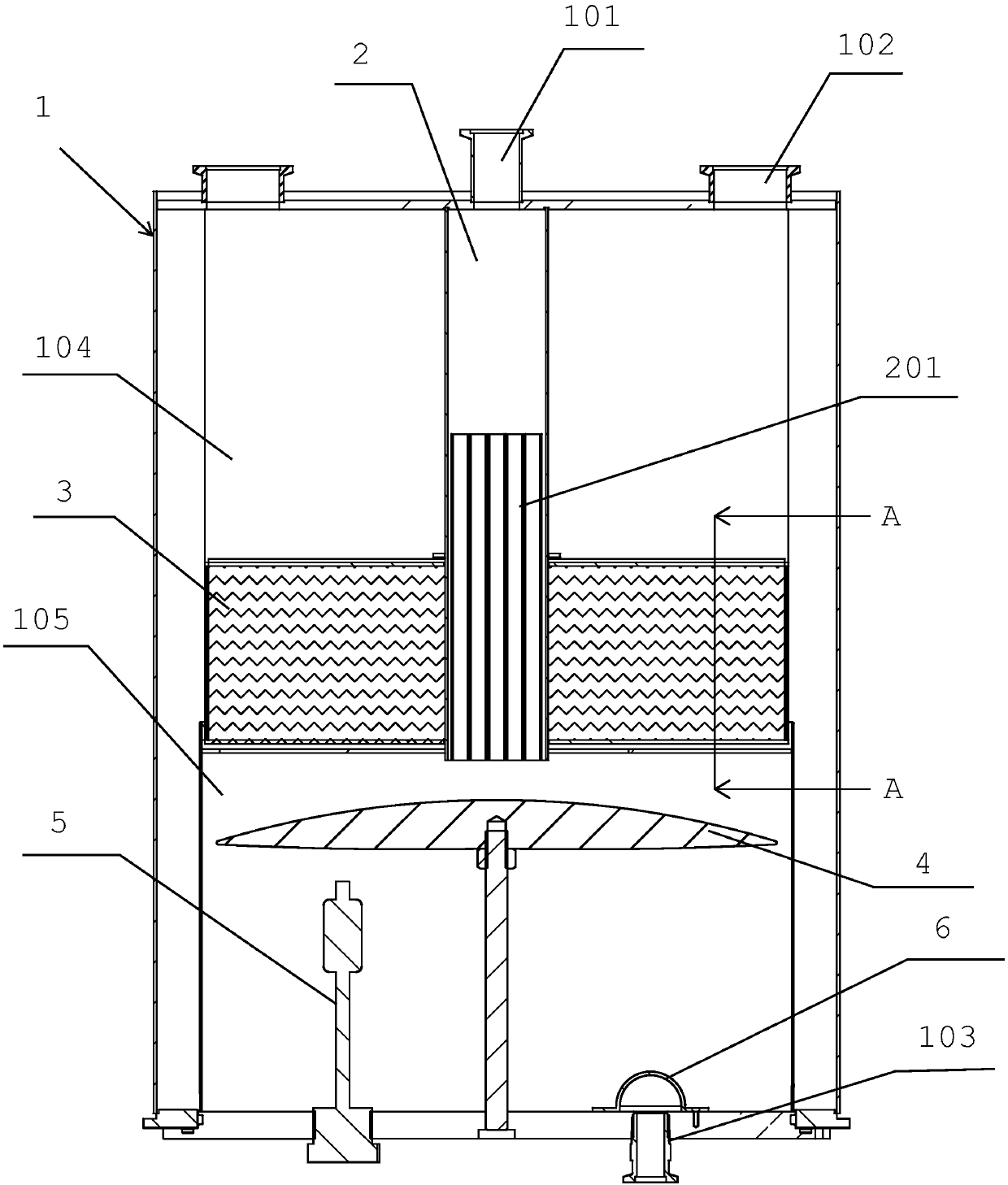

[0045] like figure 1 A transition tank shown includes a tank body 1, an air inlet 101, an air outlet 102, and a liquid discharge port 103. The air inlet 101 and the air outlet 102 are arranged on the top of the tank body 1, and the liquid outlet 103 is arranged on the top of the tank body. 1 bottom end, the tank body 1 is provided with an air intake passage 2, the upper end of the air intake passage 2 is sealed with the air inlet 101, the inner cavity of the lower half of the air intake passage 2 is provided with a condensation pipe 201, and the outside of the air intake passage 2 is sleeved with The filter screen 3 is provided with a return cover plate 4 under the air intake channel 2, and a liquid level sensor 5 is provided on the bottom surface of the inner cavity of the tank body 1.

[0046] The tank body 1 of the transition tank is divided into the upper cavity 104 and the lower cavity 105 with the filter screen 3 as the boundary, and the gas enters the tank body 1 of the...

Embodiment 2

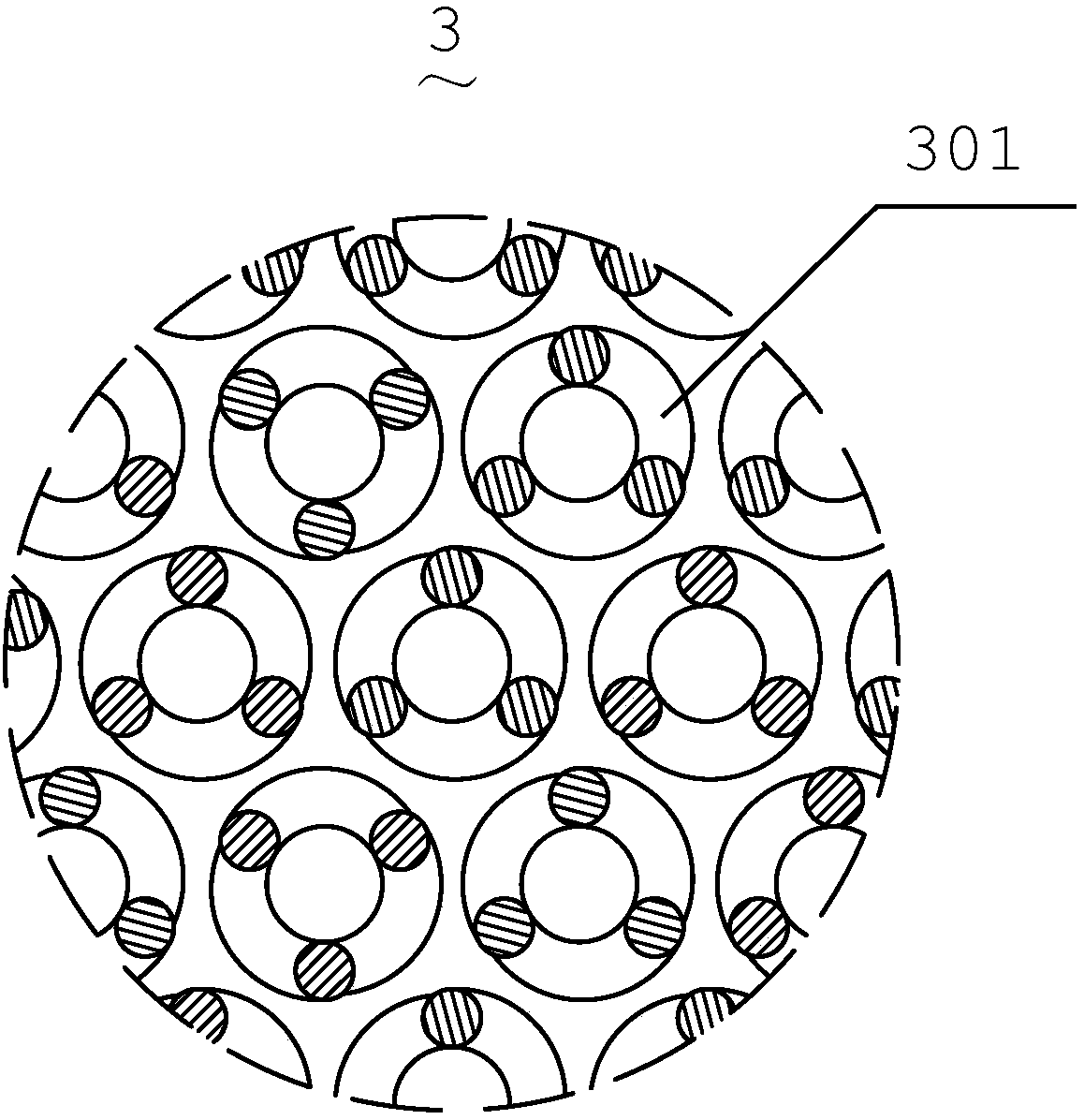

[0048] like figure 1 , figure 2 , image 3 and Figure 4 A transition tank shown includes a tank body 1, an air inlet 101, an air outlet 102, and a liquid discharge port 103. The air inlet 101 and the air outlet 102 are arranged on the top of the tank body 1, and the liquid outlet 103 is arranged on the top of the tank body. 1 bottom end, the tank body 1 is provided with an air intake passage 2, the upper end of the air intake passage 2 is sealed and connected with the air inlet 101, the inner cavity of the lower half of the air intake passage 2 is provided with a condensation pipe 201, and the outside of the air intake passage 2 is provided with The filter screen 3 is provided with a return cover plate 4 under the air intake channel 2, and a liquid level sensor 5 is provided on the bottom surface of the inner cavity of the tank body 1.

[0049]The tank body 1 of the transition tank is divided into the upper cavity 104 and the lower cavity 105 with the filter screen 3 as t...

Embodiment 3

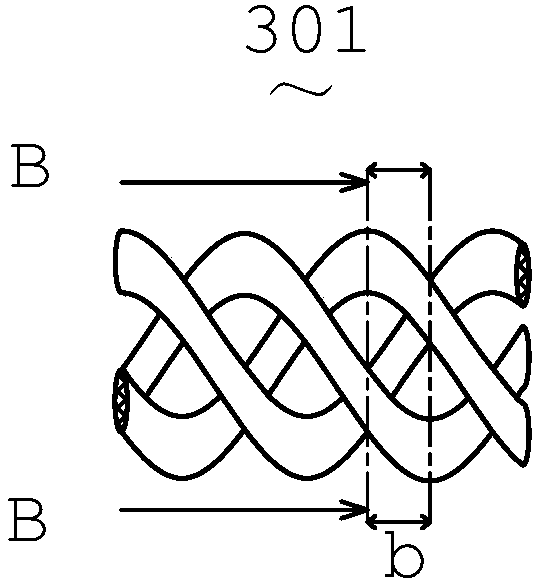

[0051] like figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 A transition tank shown includes a tank body 1, an air inlet 101, an air outlet 102, and a liquid discharge port 103. The air inlet 101 and the air outlet 102 are arranged on the top of the tank body 1, and the liquid outlet 103 is arranged on the top of the tank body. 1 bottom end, the tank body 1 is provided with an air intake passage 2, the upper end of the air intake passage 2 is sealed with the air inlet 101, the inner cavity of the lower half of the air intake passage 2 is provided with a condensation pipe 201, and the outside of the air intake passage 2 is sleeved with A filter screen 3, a return cover 4 is provided under the air intake channel 2, a liquid level sensor 5 is provided on the bottom surface of the inner cavity of the tank body 1, a buffer mechanism 7 is provided in the inner cavity of the tank body 1, and the buffer mechanism 7 is provided with an upper opening and a side opening , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com