Inductive automatic wire-replacing system for multi-head wire drawing machine

A multi-head wire drawing machine and automatic wire changing technology, applied in the field of multi-head wire drawing production, can solve the problems of knotting, waste of personnel efficiency, high frequency of material change, reduce wire breakage, improve wire change efficiency, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

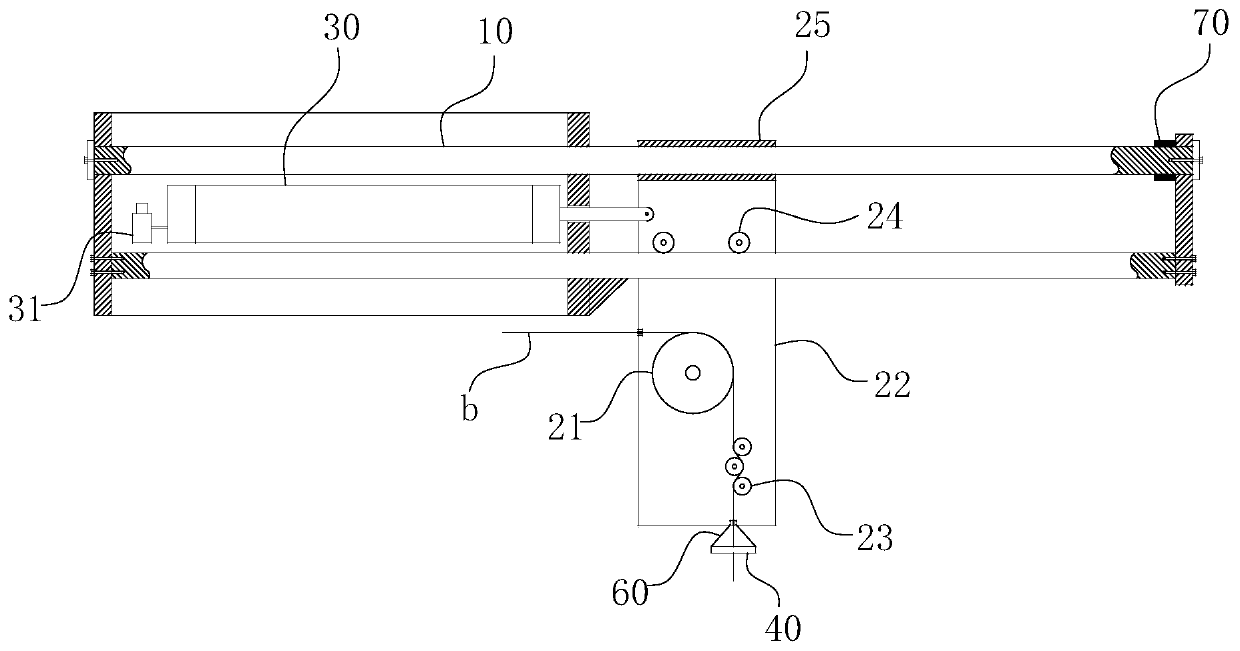

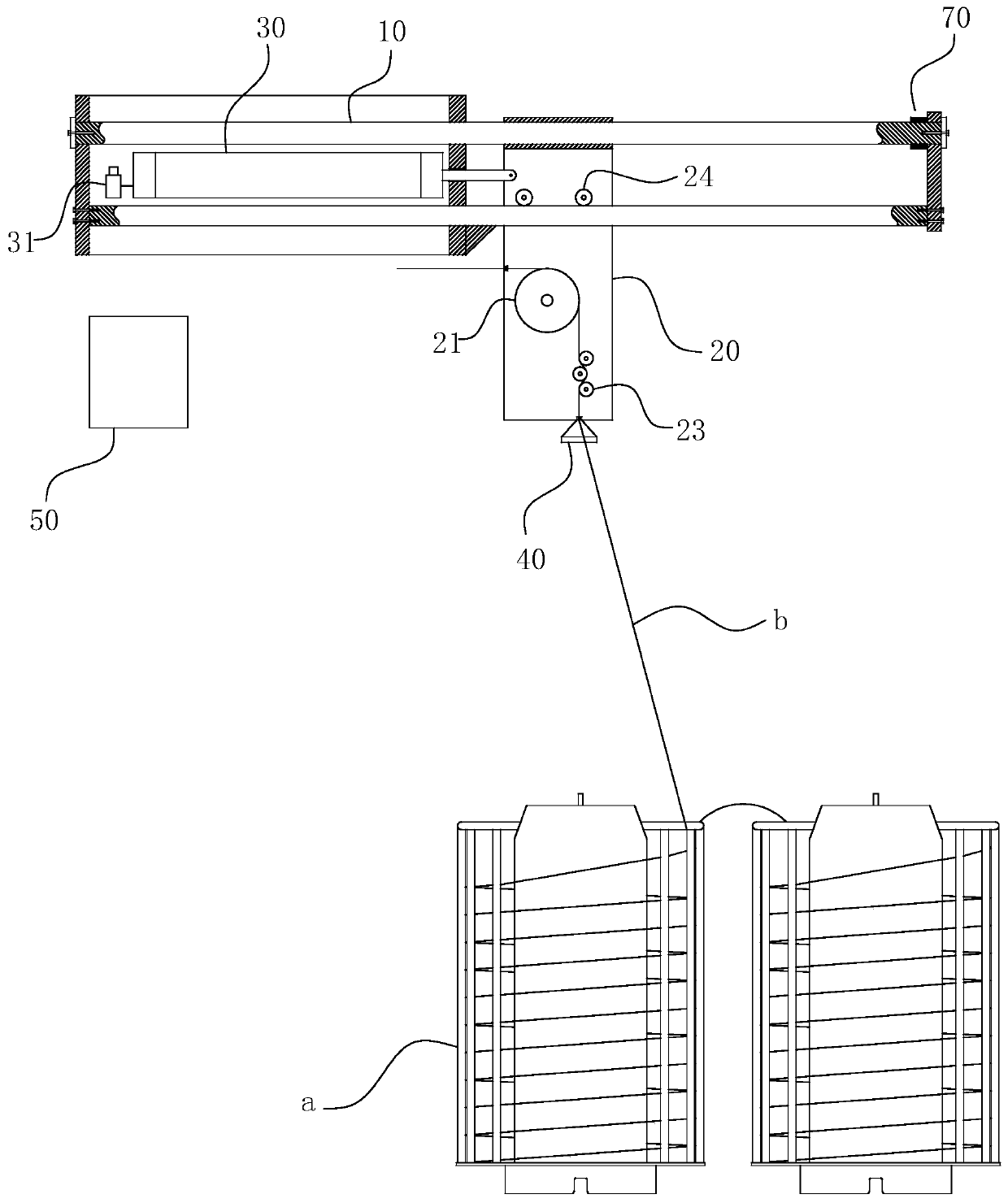

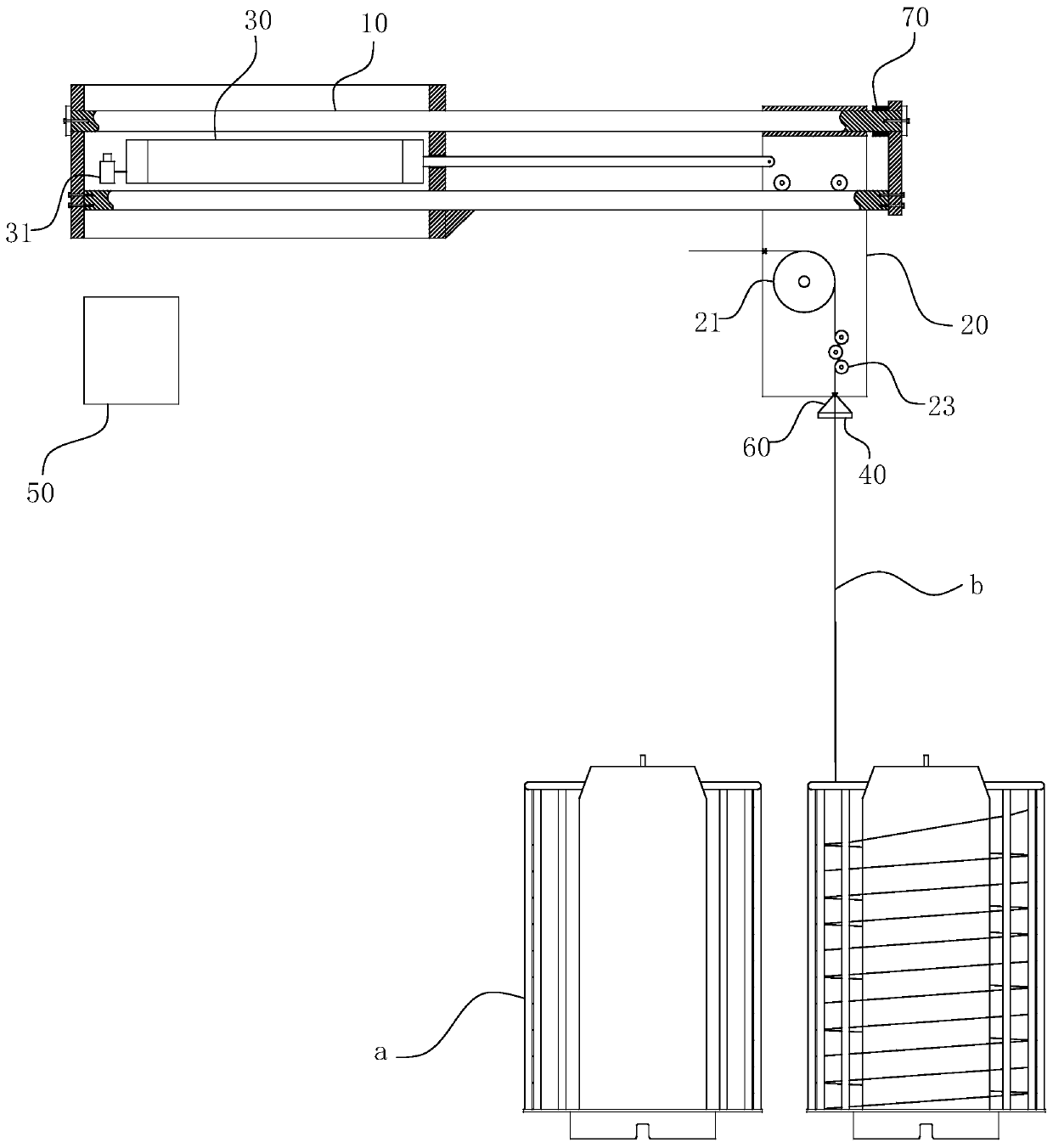

[0027] For ease of understanding, combined here Figure 1-3 , the concrete structure and working mode of the present invention are further described as follows:

[0028] The specific structure of the present invention is as Figure 1-3 As shown, its main structure includes a pay-off basket a and a mobile pay-off assembly located directly above the pay-off basket a, and the mobile pay-off assembly is then fixed on the pay-off bracket. in:

[0029] by figure 1 As an example, the mobile pay-off assembly includes a horizontal guide rail 10 , a cylinder that is a driving part 30 , a mobile boom 20 and a buffer pad 70 . And for the mobile boom 20, it is used as a carrier on the one hand, so that the reversing wheel 21, the stress wheel 23, the moving roller 24 and even the guide sleeve 25 are arranged conveniently; The purpose of reciprocating sliding relative to the horizontal guide rail 10 is achieved by relying on the cooperation of the guide sleeve 25 and the moving roller 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com