Intelligent production switching method based on electronic flexible manufacturing

A flexible manufacturing and intelligent technology, applied in the field of intelligent production conversion based on electronic flexible manufacturing, to achieve the effect of reducing the number of withdrawals, improving the efficiency of line change, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] It should be noted that the present invention provides a unique set of work order conversion and management methods, flexible work order and work order materials, and tooling conversion methods to reduce the number of material withdrawals between work orders and the initial preparation of new work orders. , The transfer of shared tooling reduces the repeated use of tooling and improves the efficiency of line change, so as to achieve the benefits of improving production efficiency and reducing production costs for enterprises.

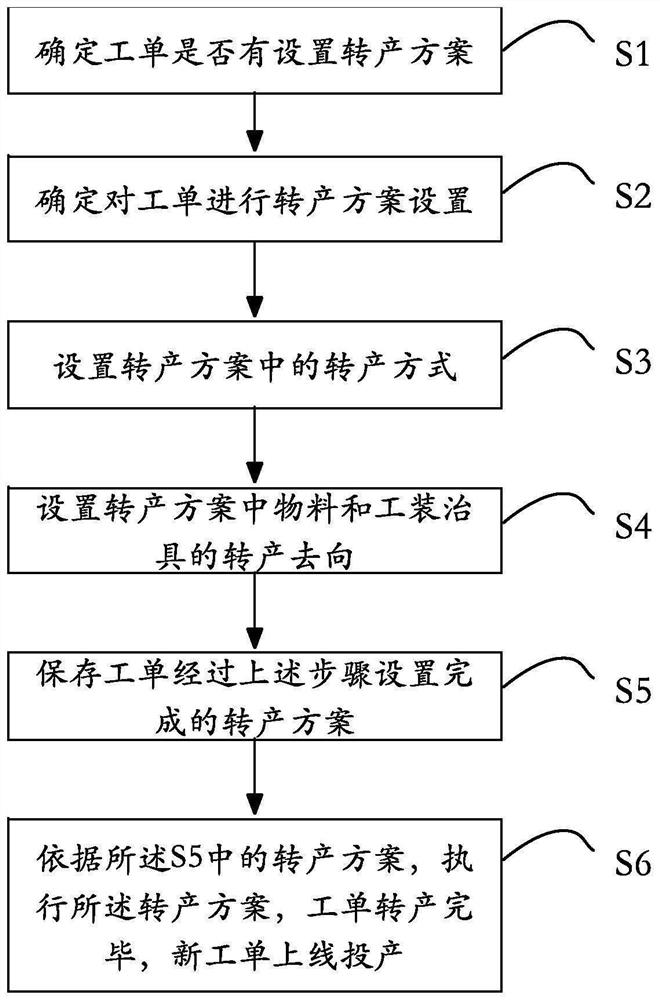

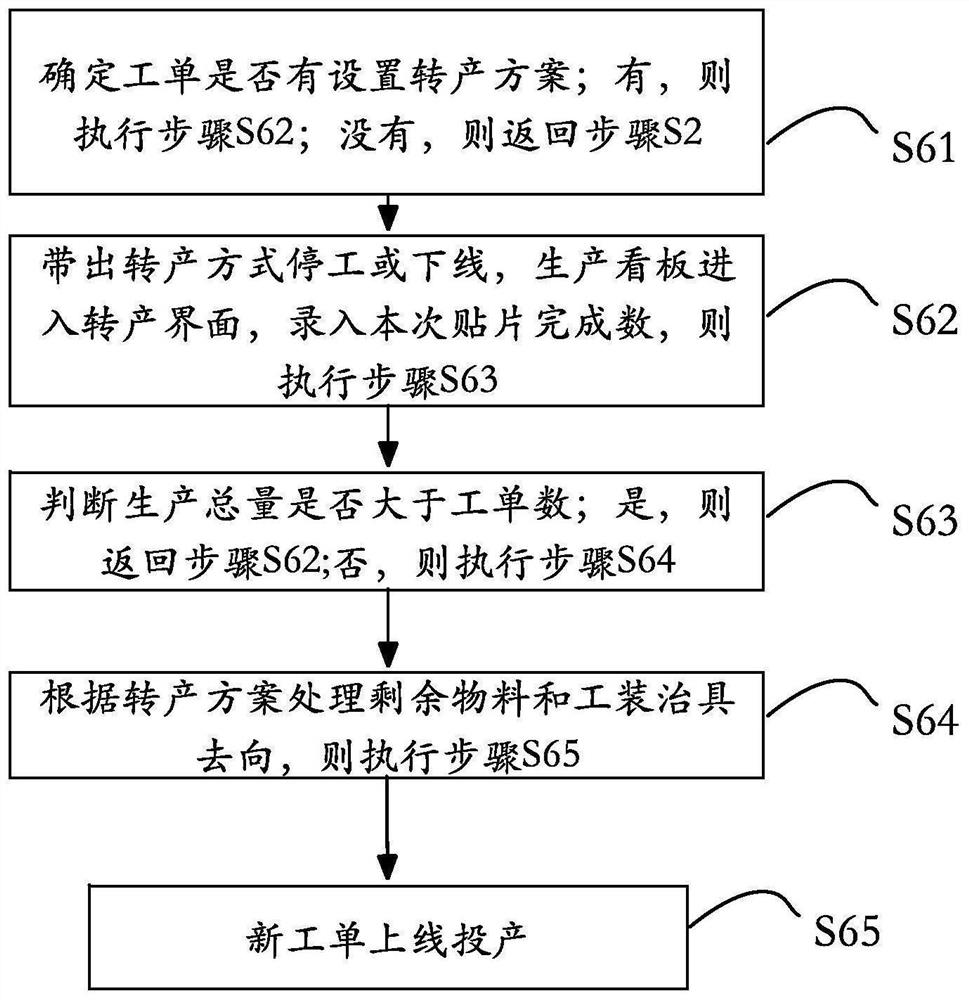

[0086] Such as figure 1 As shown, an intelligent conversion method based on electronic flexible manufacturing includes:

[0087] S1. Determine whether the work order has a production change plan; that is

[0088] S2. Determine the setting of the production change plan for the work order;

[0089] S3. Setting the production transfer mode in the production transfer plan;

[0090] S4. Set the production transfer destination of materials and tooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com