A kind of method for preparing silver-copper-zinc-tin solder strip

A solder strip, silver-copper-zinc technology, used in metal rolling, metal extrusion dies, etc., can solve the problem of irreplaceable strips, high cost of silver-copper-zinc-tin solder strips, and poor intergranular plastic coordination deformation ability, etc. problems, to avoid cracking at the edge of the plate, reduce the number of material removals, and refine the microstructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing a silver-copper-zinc-tin brazing material strip of the present embodiment comprises the following steps:

[0049] Step 1: Place pure metal Ag, pure metal Cu, pure metal Sn and pure metal Zn in the crucible of the vacuum induction furnace according to the raw material ratio of the grade of Ag55CuZnSn solder, seal the furnace, evacuate, and turn on the intermediate frequency power supply for intermediate frequency induction. Smelting to obtain molten metal, placing the molten metal in a casting mold for casting, using a sawing machine to cut the riser, and using a lathe to clean the surface to obtain a plate-shaped ingot with a size of 20mm×100mm×200mm;

[0050] Step 2, placing the plate-shaped ingot in step 1 in a resistance furnace for homogenization treatment to obtain a plate-shaped ingot after homogenization treatment; the temperature of the homogenization treatment is 500 ° C, and the holding time of the homogenization treatment is 5h; the hom...

Embodiment 2

[0058] This example is the same as Example 1, and the difference is that the first step is: placing pure metal Ag, pure metal Cu and pure metal Sn in the crucible of the vacuum induction furnace in sequence according to the ratio of raw materials, and placing pure metal Zn in the crucible of the vacuum induction furnace. In the hopper, seal the furnace, evacuate, turn on the intermediate frequency power supply to conduct intermediate frequency induction melting of the metal in the crucible, after it is completely melted and fully stirred and mixed, a melt is obtained, and then the pure metal Zn in the hopper is slowly poured into the melt to continue. Smelting for 10 min to obtain molten metal, cast the molten metal in a mold, cut the riser with a saw, and clean the surface with a lathe to obtain a plate-shaped ingot with a size of 20mm×100mm×200mm. The method of first melting and mixing metal Ag, Cu and Sn, and then adding metal Zn to continue melting can reduce the volatiliza...

Embodiment 3

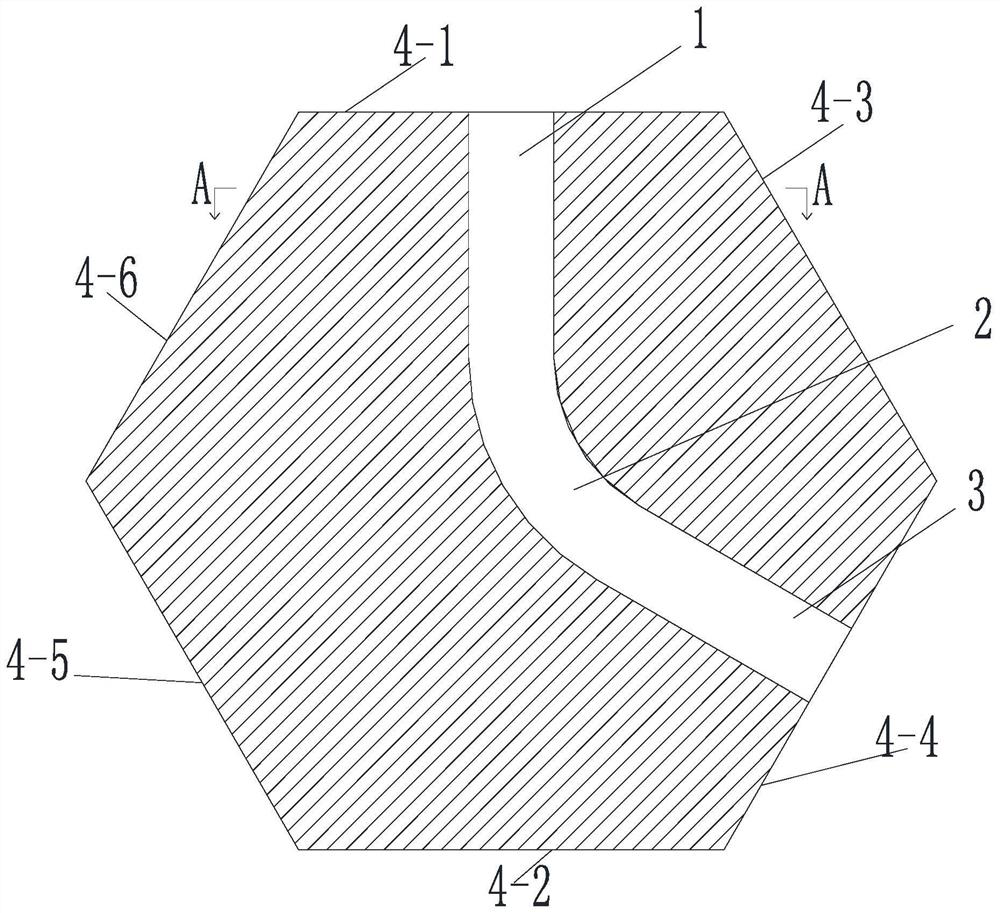

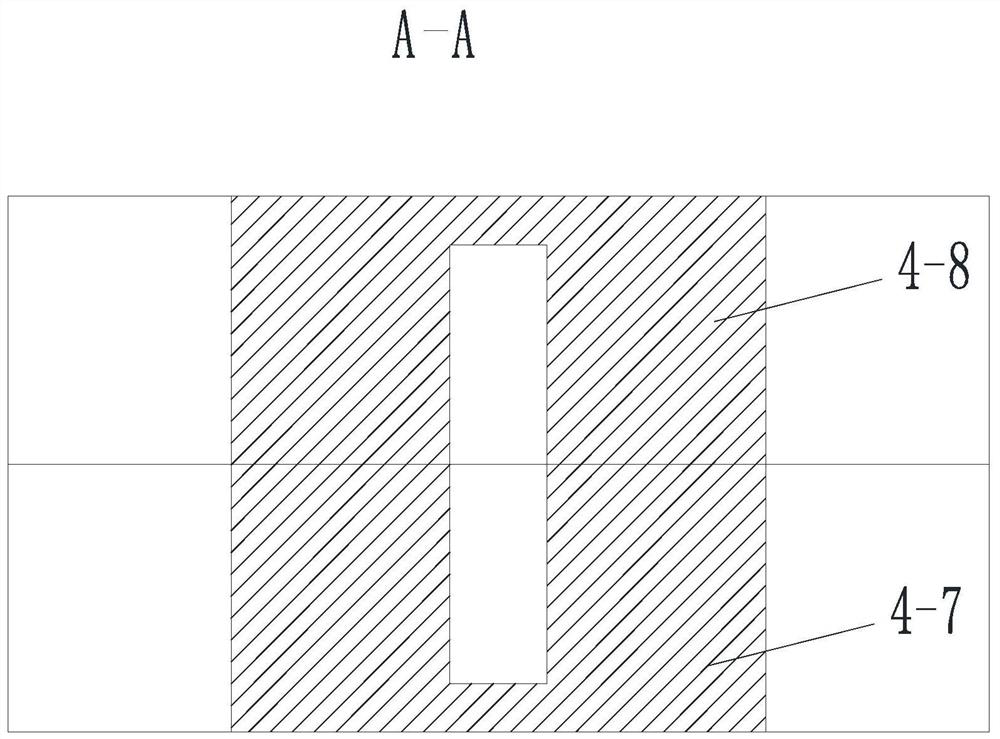

[0060] This embodiment provides an equal channel extrusion die for preparing silver-copper-zinc-tin solder strips, such as Figures 1 to 6 As shown, it includes a mold body, and an extrusion channel is arranged in the mold body, and the channel included angle of the extrusion channel is 120°;

[0061] The extrusion channel includes an upper extrusion channel 1, a lower extrusion channel 3 and a corner channel 2 arranged between the upper extrusion channel 1 and the lower extrusion channel 3. One end of the corner channel 2 is connected to the upper extrusion channel 1. Communication, the other end of the corner channel 2 communicates with the lower extrusion channel 3 .

[0062] The upper extrusion channel, the corner channel and the lower extrusion channel are connected in sequence to form the extrusion channel; these channel extrusion dies are used for the equal channel extrusion of the raw material ingot, and the ingot has a fine internal structure after shear deformation. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com