A parallel reciprocating linear filling optimization method and system

A technology of reciprocating straight lines and parallel straight lines, applied in processing and manufacturing, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve problems such as poor filling accuracy at corners, reduce system stability, and printer loss, so as to avoid sudden changes and reduce The effect of the number of withdrawals, improving the processing speed and the precision of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

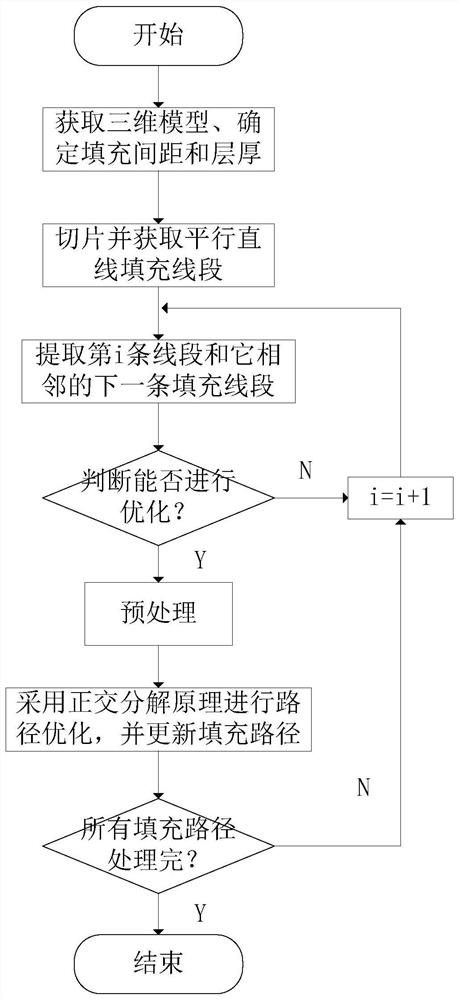

[0035] see figure 1 , this embodiment provides a parallel reciprocating straight line filling optimization method, including the following steps:

[0036] S1: Obtain the 3D model of the 3D entity to be printed, and determine the filling distance d;

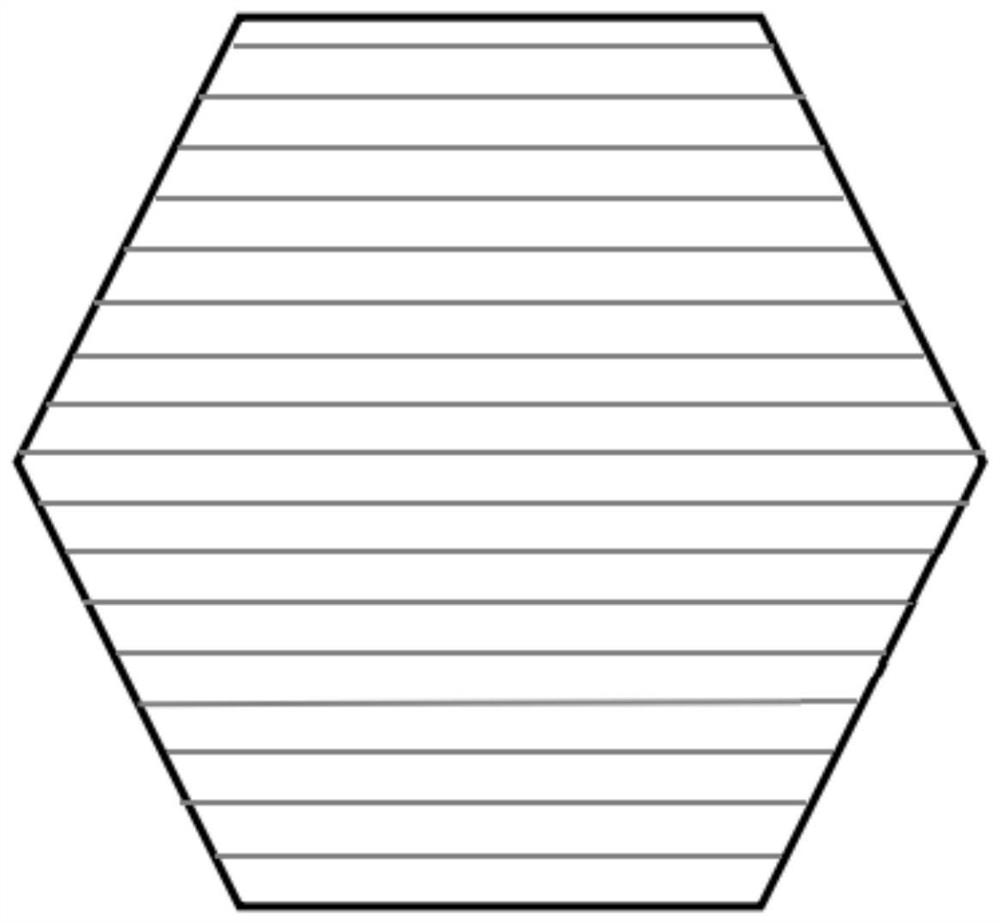

[0037] S2: Slicing and layering the 3D model, using the existing parallel reciprocating straight line filling method to obtain the parallel straight line filling line segments of each layer of the 3D model in the plane;

[0038] S3: Traversing the parallel line filling line segments, and judging whether two adjacent parallel line filling line segments in the same layer meet the path optimization conditions, if so, go to step S4, if not, use the partition algorithm to divide the adjacent two parallel line The filled line segment is preprocessed, and after regenerating the filled line segment, enter step S4;

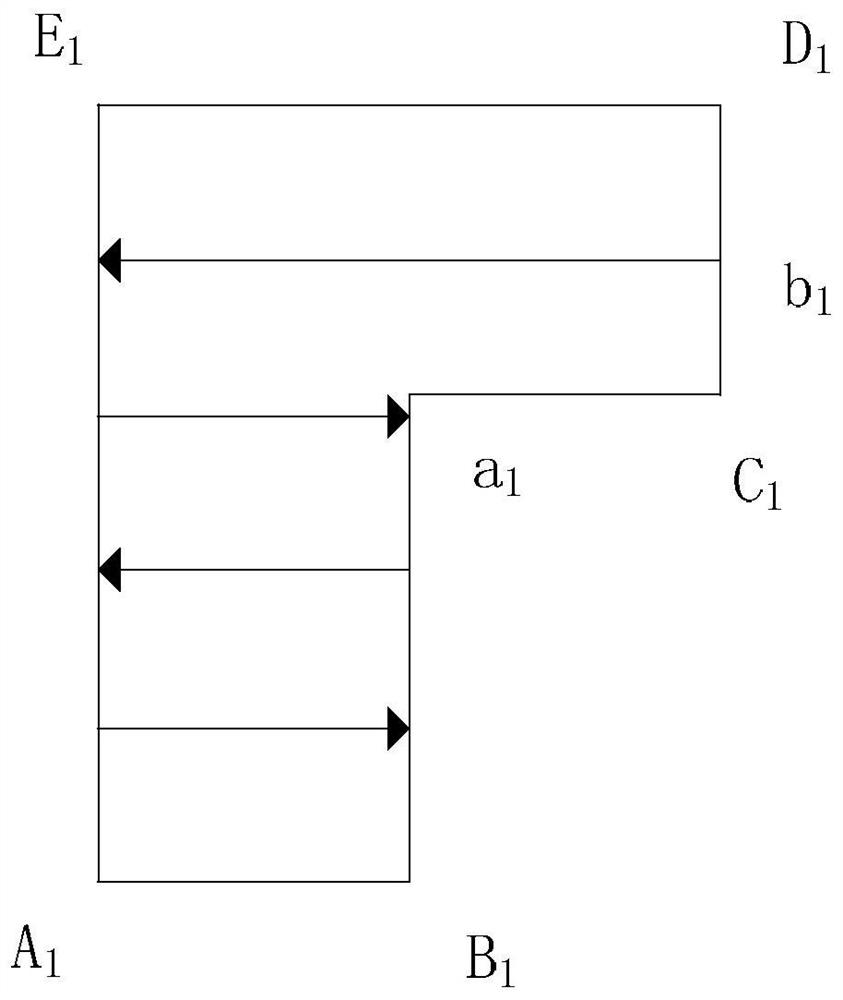

[0039] S4: Use the orthogonal decomposition principle to optimize the filling path at the corners of two adjacent parallel...

Embodiment 2

[0059] Corresponding to the above method embodiments, this embodiment provides a parallel reciprocating linear filling system, including a memory, a processor, and a computer program stored in the memory and operable on the processor, the processor The steps of the above method are realized when the program is executed.

[0060] As mentioned above, the present invention provides a parallel reciprocating straight line filling optimization method and system, on the basis that the printer can keep the line speed constant through the orthogonal decomposition of the movement, and convert the existing parallel filling reciprocating corners into standard arc curves , path optimization can reduce the idling corners between two parallel printing paths, thereby avoiding sudden changes in printing speed, reducing idling routes and the number of material withdrawals, improving rapid prototyping processing speed and part precision, and maintaining the same online speed In the case of chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com