Efficient ceramic automatic glaze spraying device

A ceramic and automatic technology is applied in the field of efficient ceramic automatic glaze spraying device, which can solve the problems of inability to meet batch ceramic production and low spraying efficiency, and achieve the effect of satisfying batch production and improving spraying quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

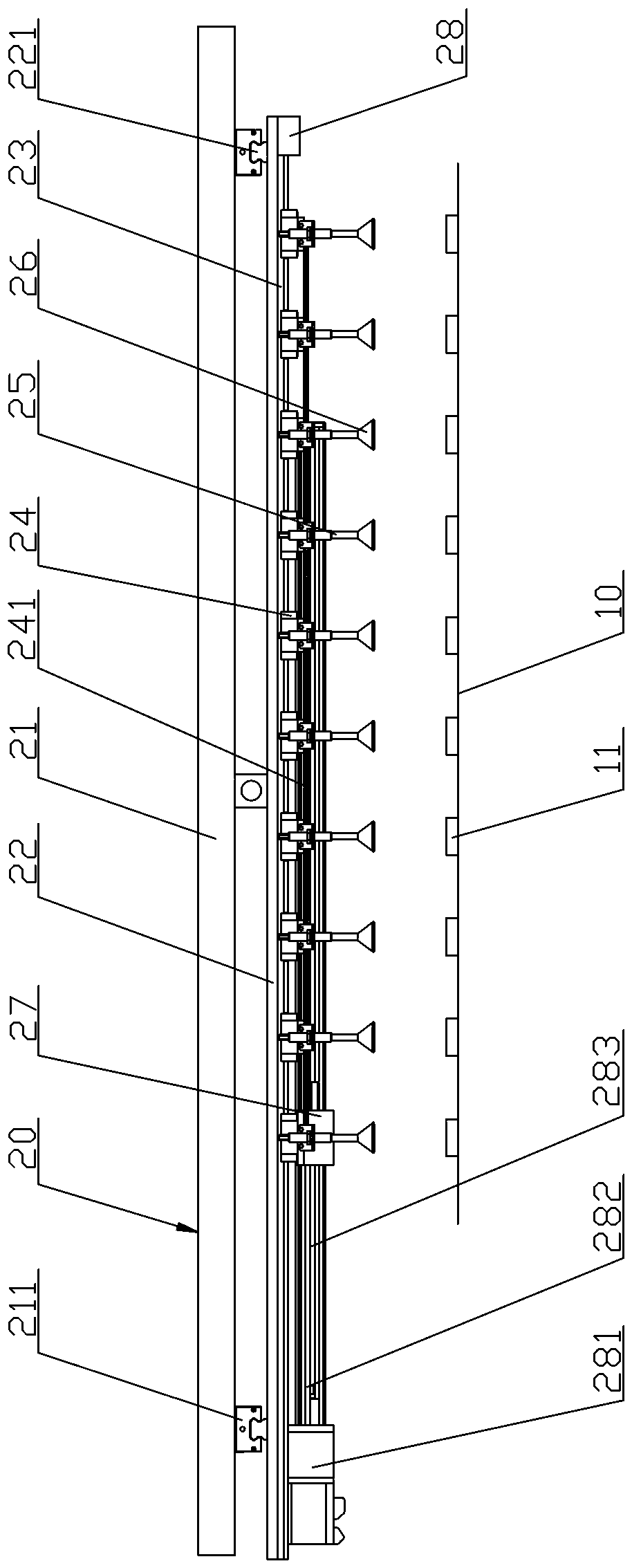

[0018] A high-efficiency ceramic automatic glaze spraying device, refer to figure 1 , including a ceramic conveying line 10 and an automatic glaze spraying mechanism 20 located above the ceramic conveying line 10, a number of positioning fixtures 11 are arranged at equal intervals on the ceramic conveying line 10, and ceramic bodies are placed on the positioning fixtures 11.

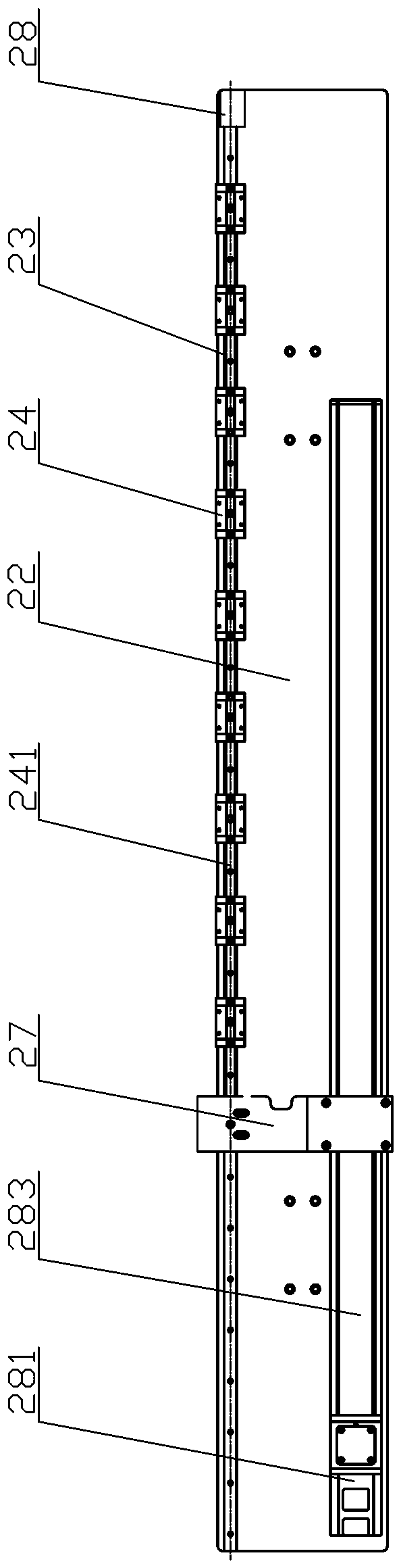

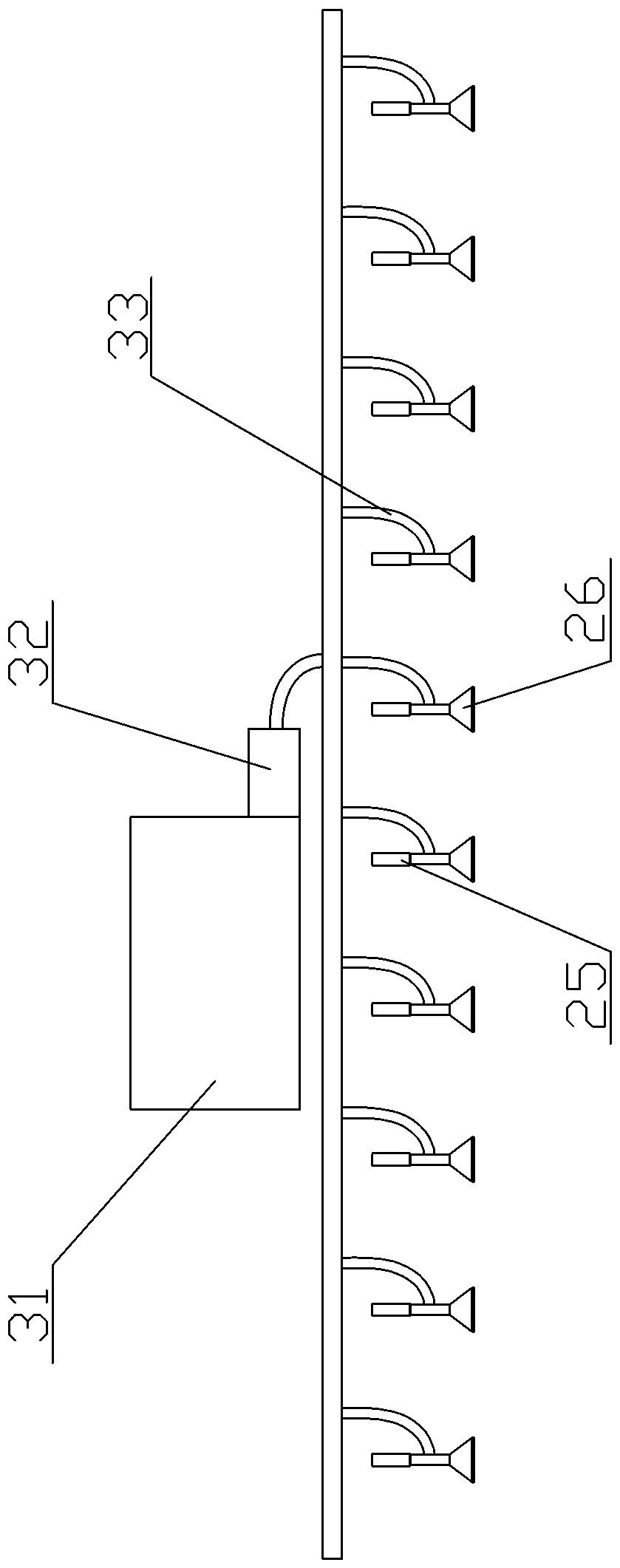

[0019] refer to figure 1 and figure 2 The above-mentioned automatic glaze spraying mechanism 20 includes a fixed plate 21, a base plate 22, a horizontal linear guide rail 23, a slider 24, a nozzle bracket 25, a nozzle 26 and a lateral drive mechanism, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com