An improved textile winding machine

A winding machine, an improved technology, applied in the textile field, can solve problems such as lack, yarn off-line, center shift, etc., and achieve the effect of stable winding performance, good stability, and large range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

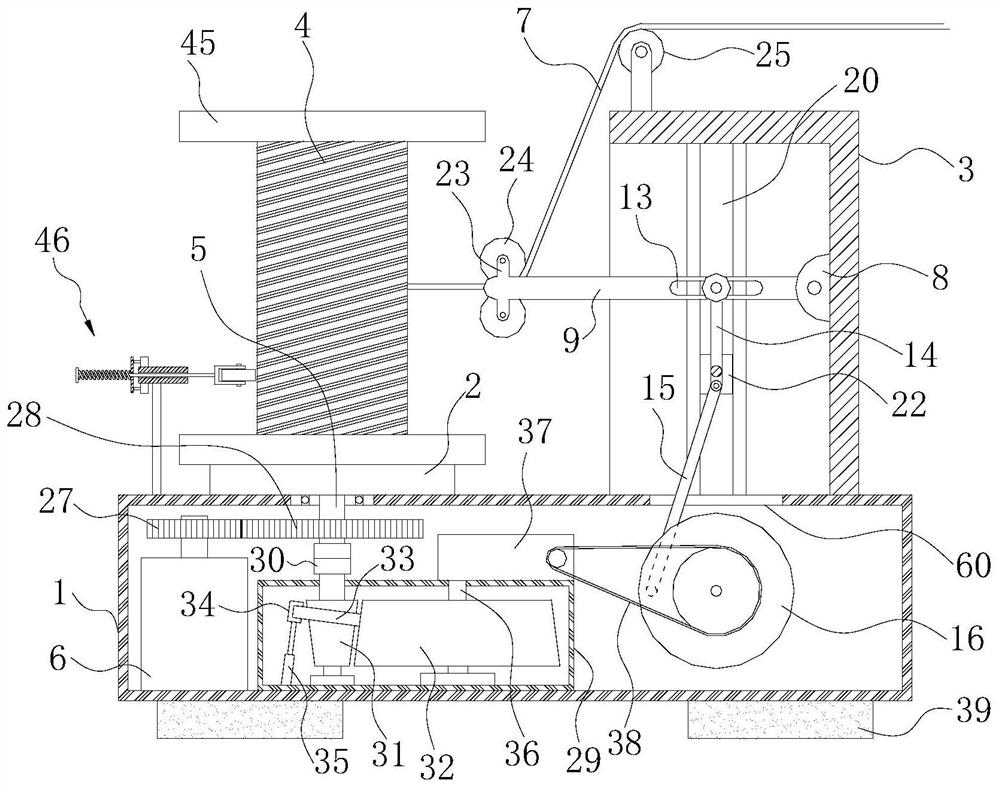

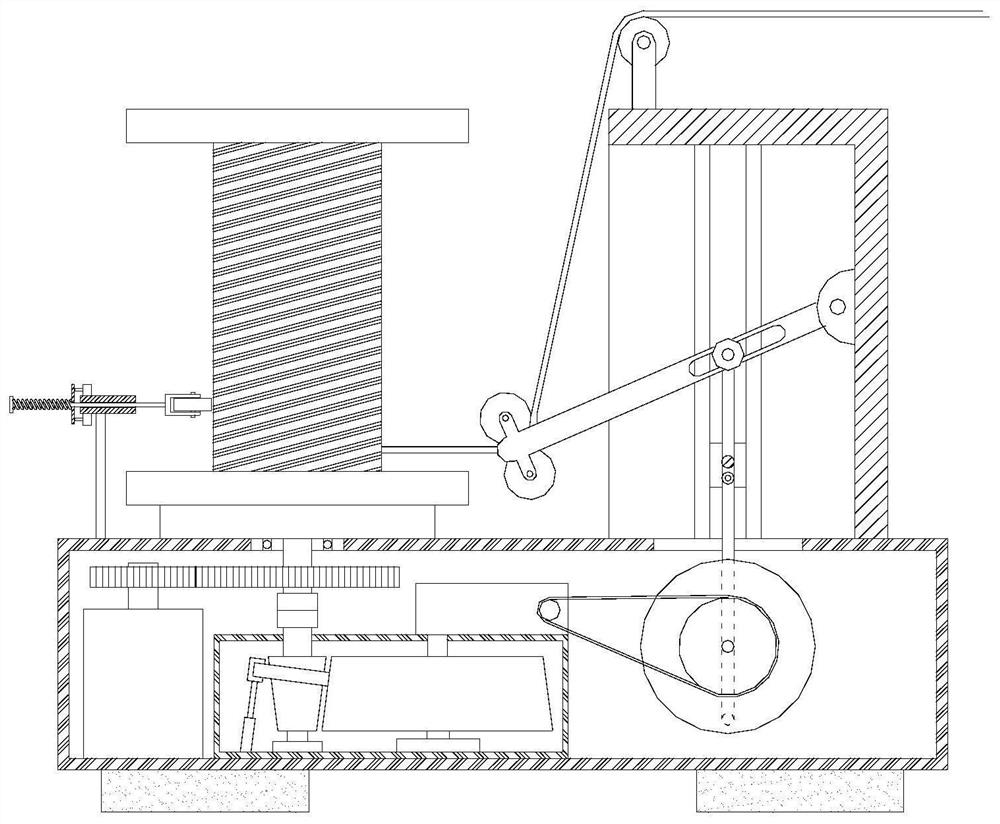

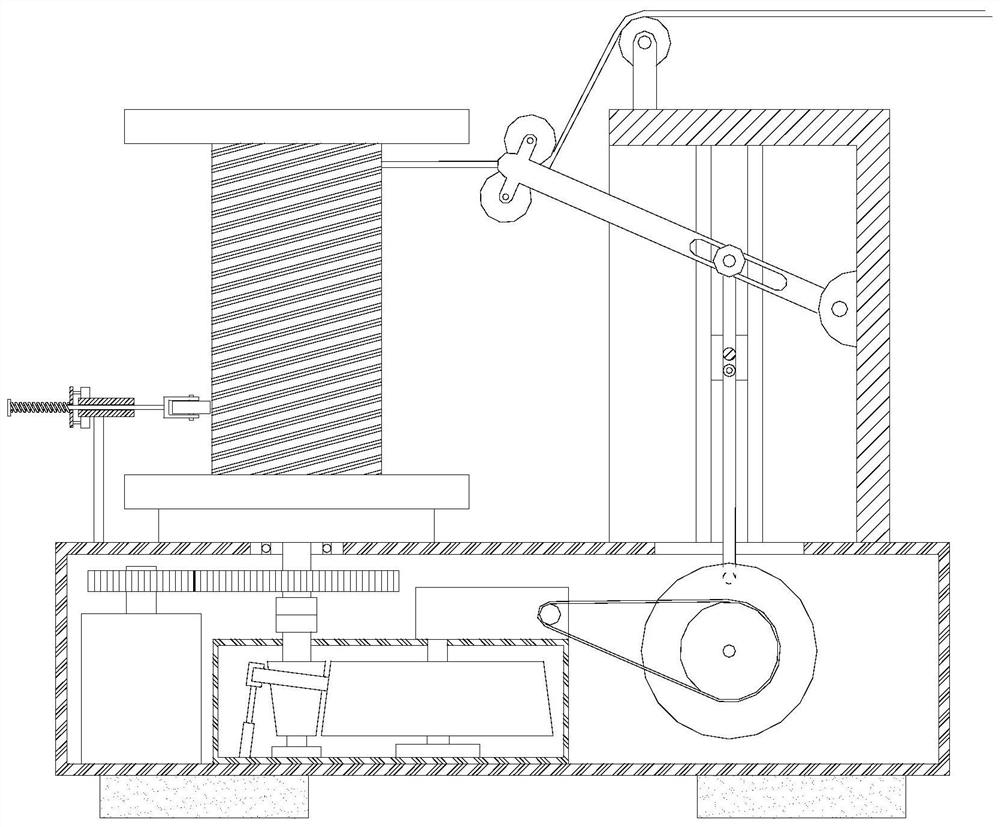

[0026] Such as Figure 1-7 An improved textile winding machine shown, such as figure 1 As shown, it includes a machine base, which is composed of a box-shaped base 1, a rotating disk 2 arranged on the top surface of the left side of the base 1, and an installation cover 3 arranged on the top surface of the right side of the base 1. In order to improve the base 1 To prevent stability, it is preferable that the bottom of the base 1 is provided with a plurality of rubber feet 39 . The bobbin 4 is arranged on the rotating disk 2, that is to say, the bobbin 4 is installed on the rotating disk 2, and the inside of the installation cover 3 is provided with a swing-type guide mechanism, and the swing-type guide mechanism is passed up and down. The mechanism that swings the yarn to change the winding position of the yarn on the bobbin 4. Regarding the drive of the rotating disc 2, the center of the bottom surface of the rotating disc 2 in the present invention is fixedly provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com