Systems and processes for plasma filtering

A plasma and semiconductor technology, applied in the field of semiconductor systems, can solve problems such as destroying substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

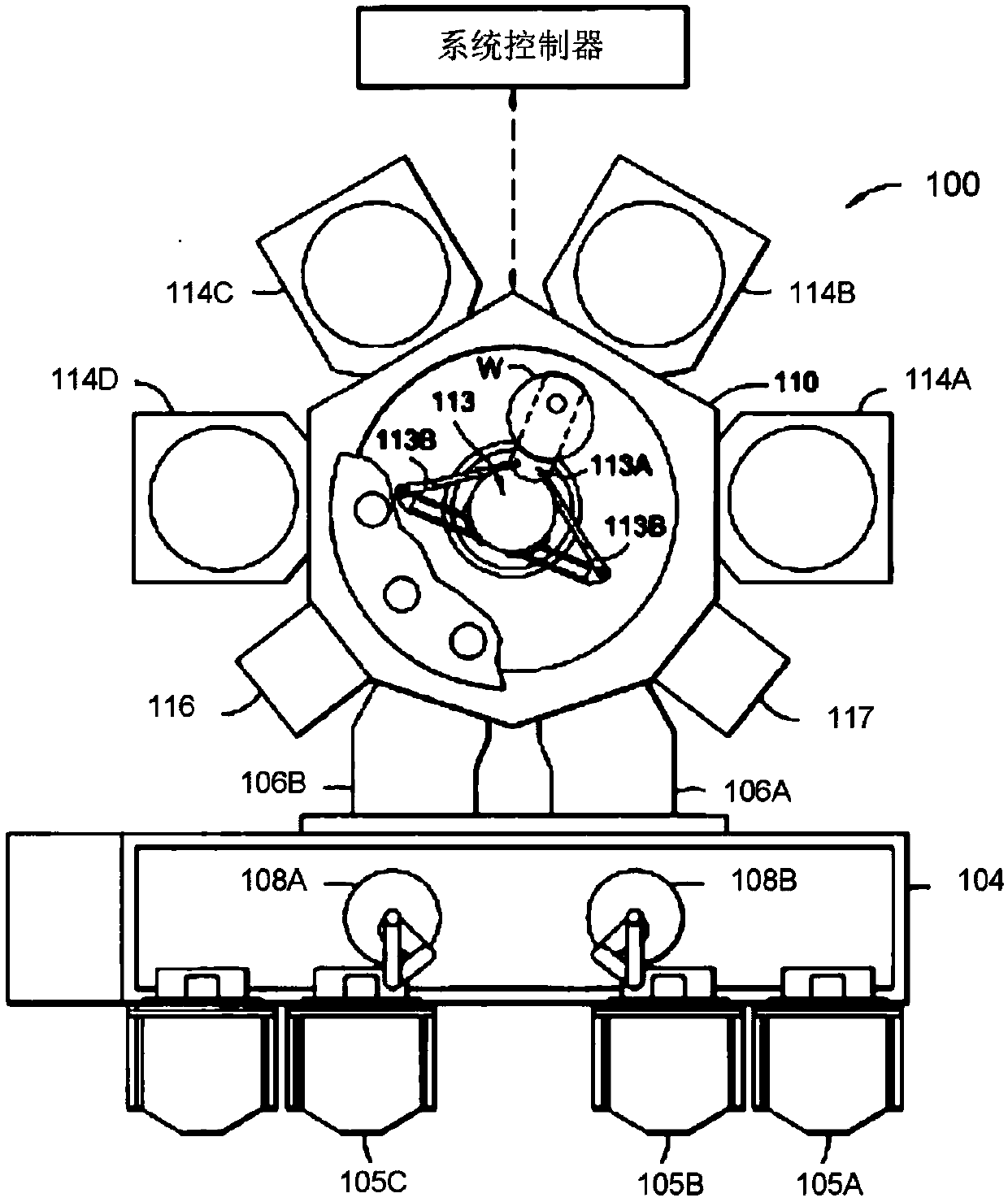

[0020] The technology includes systems and components for semiconductor processing of fine pitch features. As line spacing decreases, standard lithographic processes may be limited and alternative mechanisms may be used in patterning. Conventional techniques have focused on these minimal patterning and removal operations, especially when the exposed material on the substrate can include numerous different features and materials, some to be etched away and some to remain.

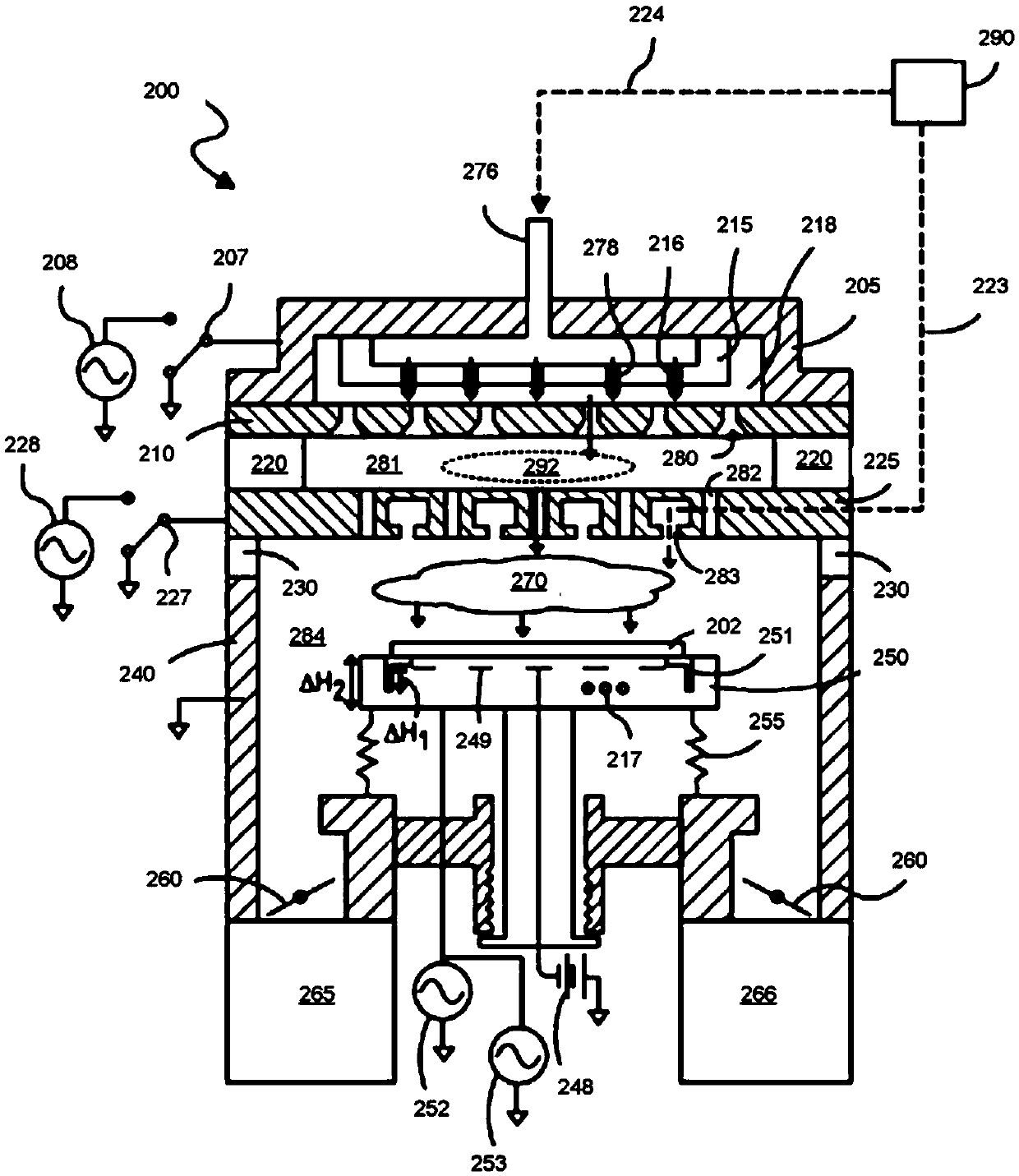

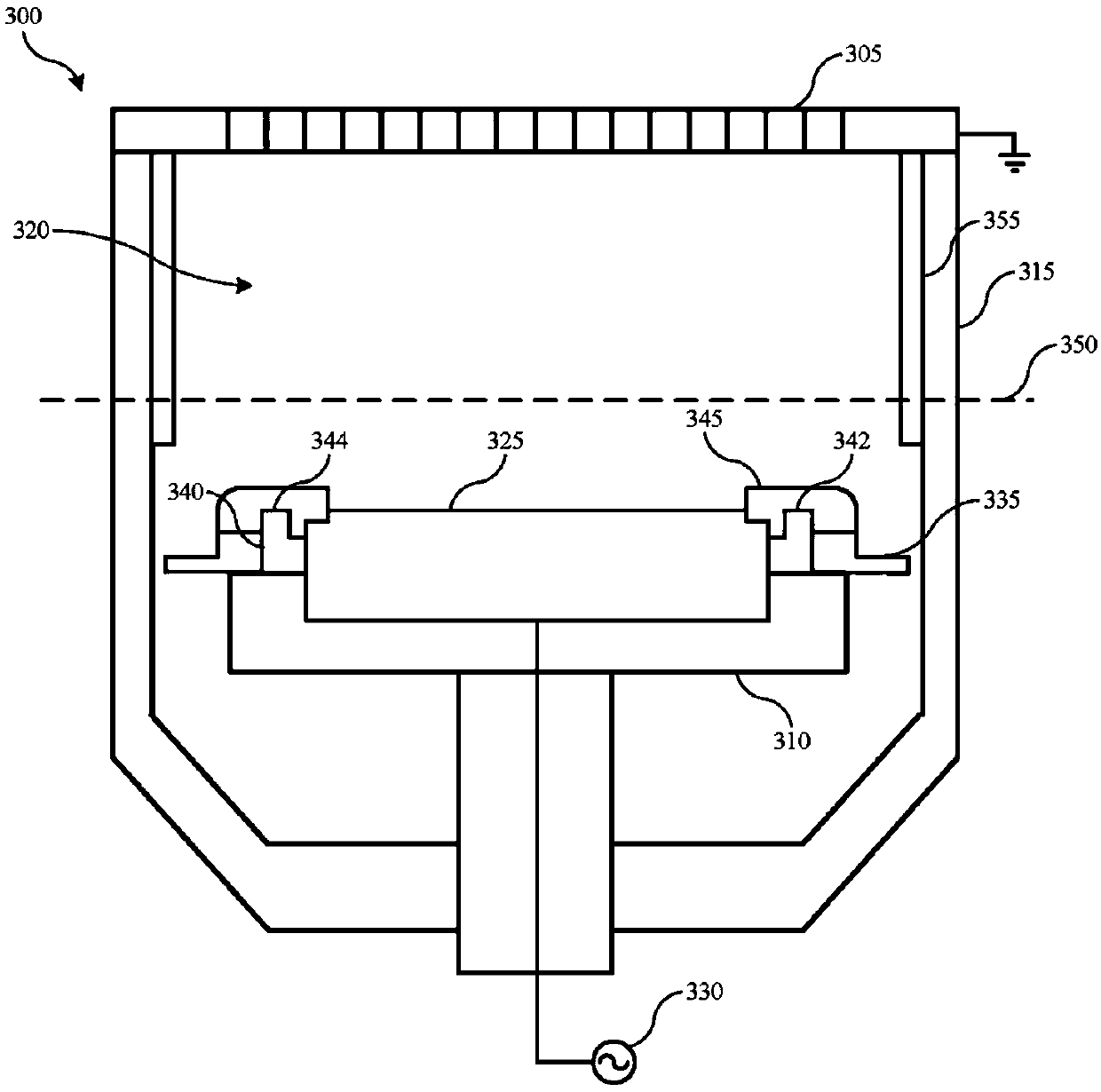

[0021] Atomic layer etching is a method that utilizes a multi-operation process that destroys or modifies the surface of a material followed by an etching operation. Etching operations can be performed under chamber conditions that allow removal of modified material but limit interaction with unmodified material. This method can then be cycled any number of times to etch additional material. Some chambers available can perform both operations within a single chamber. The modification can be performed usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com