A binder, negative electrode slurry using it, its preparation method and application

A negative electrode slurry and binder technology, applied in negative electrodes, structural parts, battery electrodes, etc., can solve the problems of coulombic efficiency and cycle life to be improved, lithium-ion battery capacity decay, and cycle life to be improved, etc. Industrial mass production application, increasing lithium ion conductivity, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

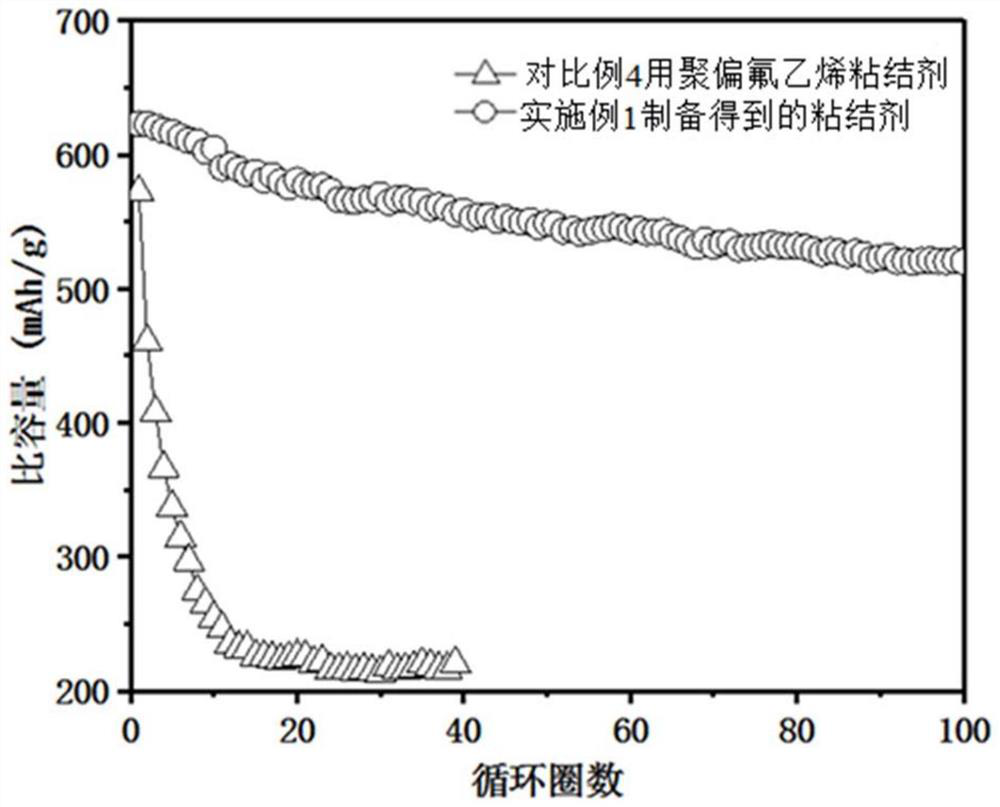

Embodiment 1

[0046] This embodiment provides a kind of binding agent, and described binding agent comprises the sodium alginate that mass percent content is 40%, the cyclodextrin of 40% and the lithium salt of 20%, wherein cyclodextrin is α-ring The combination of dextrin and β-cyclodextrin, the mass ratio of α-cyclodextrin and β-cyclodextrin is 1:1, the lithium salt is the combination of lithium oxalate and lithium carbonate, the mass ratio of lithium oxalate and lithium carbonate is 1:1.

[0047] The preparation method of the binder comprises: dissolving 300g of sodium alginate, 300g of cyclodextrin and 150g of lithium salt in 3500g of deionized water and mixing to obtain the binder.

[0048] The negative electrode slurry includes 80% by mass of silicon-based material (SiC600), 5% of conductive additive (SP) and 15% of the binder prepared above.

[0049] The preparation method of the negative electrode slurry includes: dissolving 4000g of silicon-based materials, 250g of conductive addi...

Embodiment 2

[0060] This embodiment provides a kind of binding agent, and described binding agent comprises the sodium alginate that mass percentage content is 75%, the cyclodextrin of 20% and the lithium salt of 5%, wherein cyclodextrin is α-ring The combination of dextrin and β-cyclodextrin, the mass ratio of α-cyclodextrin and β-cyclodextrin is 3:1, the lithium salt is the combination of lithium oxalate and lithium carbonate, the mass ratio of lithium oxalate and lithium carbonate is 4:1.

[0061] The preparation method of the binder includes: dissolving 562.5g of sodium alginate, 30g of cyclodextrin and 7.5g of lithium salt in 700g of deionized water and mixing to obtain the binder.

[0062] The negative electrode slurry includes 96% by mass of silicon-based material (SiC600), 1% of conductive additive (SP) and 3% of the binder prepared above.

[0063] The preparation method of the negative electrode slurry includes: dissolving 4800g of silicon-based material, 50g of conductive additi...

Embodiment 3

[0071] This embodiment provides a kind of binding agent, and described binding agent comprises the sodium alginate that mass percentage content is 50%, the cyclodextrin of 35% and the lithium salt of 15%, wherein cyclodextrin is α-ring The combination of dextrin and β-cyclodextrin, the mass ratio of α-cyclodextrin and β-cyclodextrin is 2:1, the lithium salt is the combination of lithium oxalate and lithium carbonate, the mass ratio of lithium oxalate and lithium carbonate is 2:1.

[0072] The preparation method of the binder comprises: dissolving 375g of sodium alginate, 262.5g of cyclodextrin and 112.5g of lithium salt in 3500g of deionized water and mixing to obtain the binder.

[0073] The negative electrode slurry includes 90% by mass of silicon-based material (SiC600), 3% of conductive additive (SP) and 7% of the binder prepared above.

[0074] The preparation method of the negative electrode slurry includes: dissolving 4500g of silicon-based material, 150g of conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com