Straw picking filament rubbing device used for furrows and ridges

A straw and furrow technology, applied in the field of straw picking and kneading devices, can solve problems such as waste, low efficiency, and need for manual collection, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

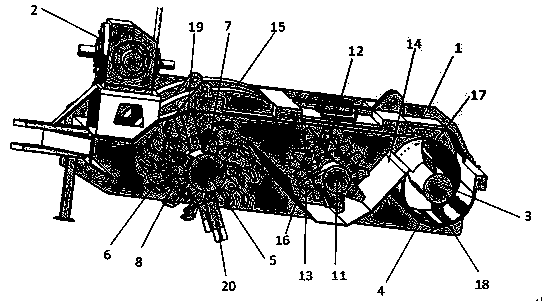

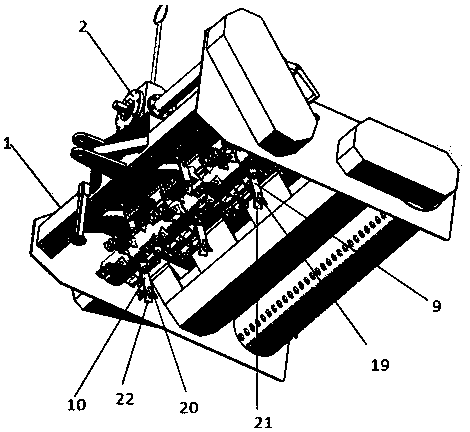

[0017] combine figure 1 and figure 2 It can be seen that a straw picking and kneading device for furrows and ridges includes an integrated pick-up shell 1, a gearbox 2 is arranged at the upper end of the pick-up shell 1, and a bottom rear end of the pick-up shell 1 An auger conveying mechanism is provided, and a hammer claw picking-up mechanism is arranged at the bottom front end of the pickup shell 1 .

[0018] The auger conveying mechanism includes a first transmission shaft 3 on which a continuous spiral conveying piece 4 arranged along the length direction of the first transmission shaft 3 is arranged. The first transmission shaft 3 is also provided with a strip-shaped first sawtooth piece 17 and a second sawtooth piece 18 , and the angle between the first sawtooth piece 17 and the second sawtooth piece 18 is 180 degrees.

[0019] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com