Slag salvaging and wringing treatment system

A technology for dry treatment and slag collection, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems such as the specific structure of the undisclosed pressing mechanism, so as to reduce the squeezing work and the process. Process, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

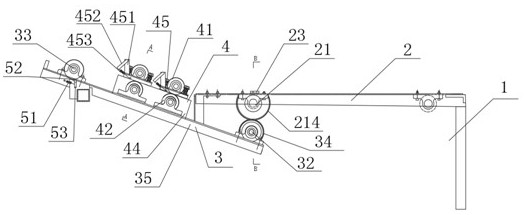

[0044] Such as figure 1 with figure 2 As shown, a slag removal and squeezing treatment system includes

[0045] A flotation tank 1, the bottom of which is provided with an aeration structure for floating the slag in the flotation tank 1;

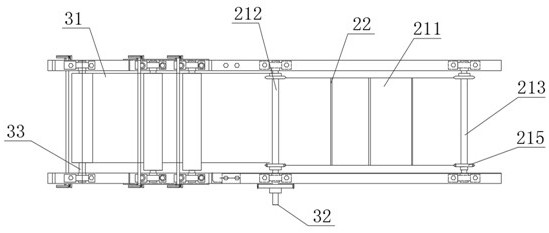

[0046] The slag removal device 2 includes a transmission structure 21 and a slag removal structure for picking up the upper scum in the flotation tank 1 under the action of the transmission structure 21;

[0047] The conveying structure 3 is used for receiving and conveying the slag picked up by the slag removing device 2;

[0048] Squeeze the structure 4 to dry the slag conveyed by the conveying structure 3;

[0049] And a collection structure to collect the squeezed slag;

[0050] The transmission structure 3 includes a second power assembly and a second transmission member 31 that is driven under the action of the second power assembly, and the second transmission member 31 is used to transport slag;

[0051] Described extruding str...

Embodiment 2

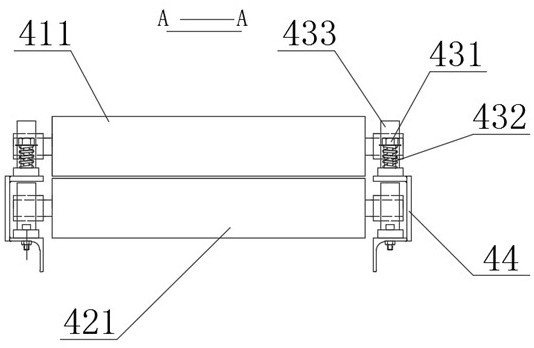

[0079] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, the scraper mechanism 45 includes a scraper bracket 451, a scraper shaft 452 and a scraper 453, one end of the scraper bracket 451 is rotatably connected to the scraper shaft 452, and one end of the scraper 453 is fixedly connected to the scraper shaft 452, The other end is in contact with the outer contour of the first extrusion wheel 411, and a first tension spring 454 is connected between the scraper shaft 452 and the first extrusion assembly 41 to press the scraper 453 to the first extrusion wheel 411, so One end of the first extrusion wheel 411 is connected with a bearing 456, the bearing 456 is equipped with a bearing seat (the bearing seat is not shown in the figure) that limits the rotation of the outer ring of the bearing 456, and the other end of the scraper bracket 451 is connected to the bearing The seat is fixedly connected.

[0080] The coaxiality between the bearing 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com