High frequency quenching equipment

A high-frequency quenching and equipment technology, applied in the field of heat treatment, can solve the problems of too much coolant in the cooling box, inconvenient to pick up the workpiece, etc., and achieve the effect of convenient picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

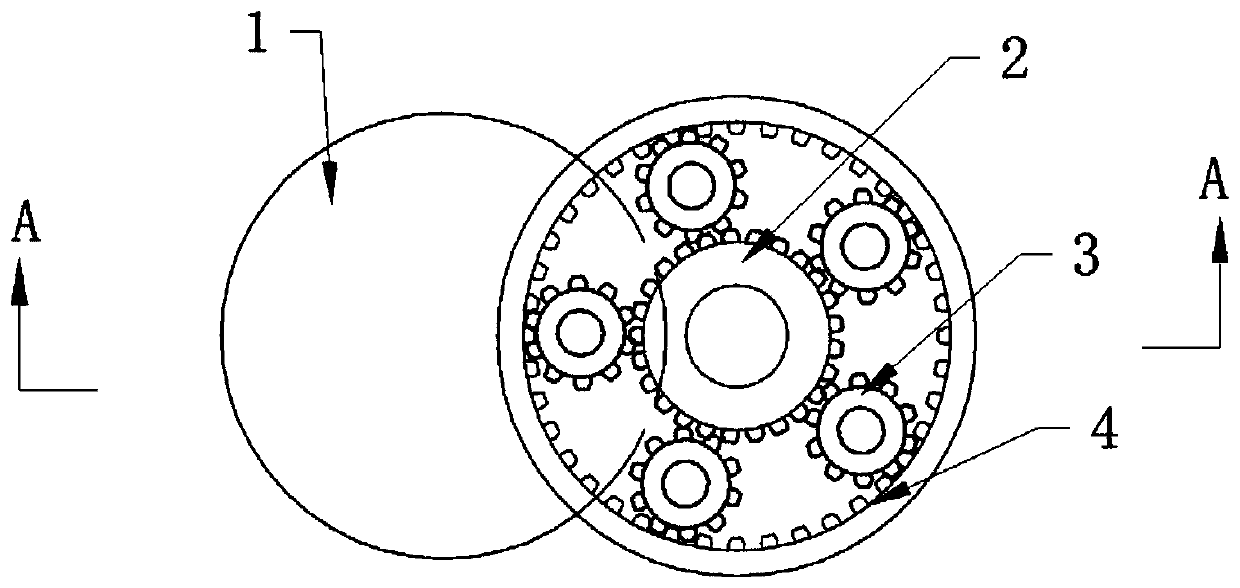

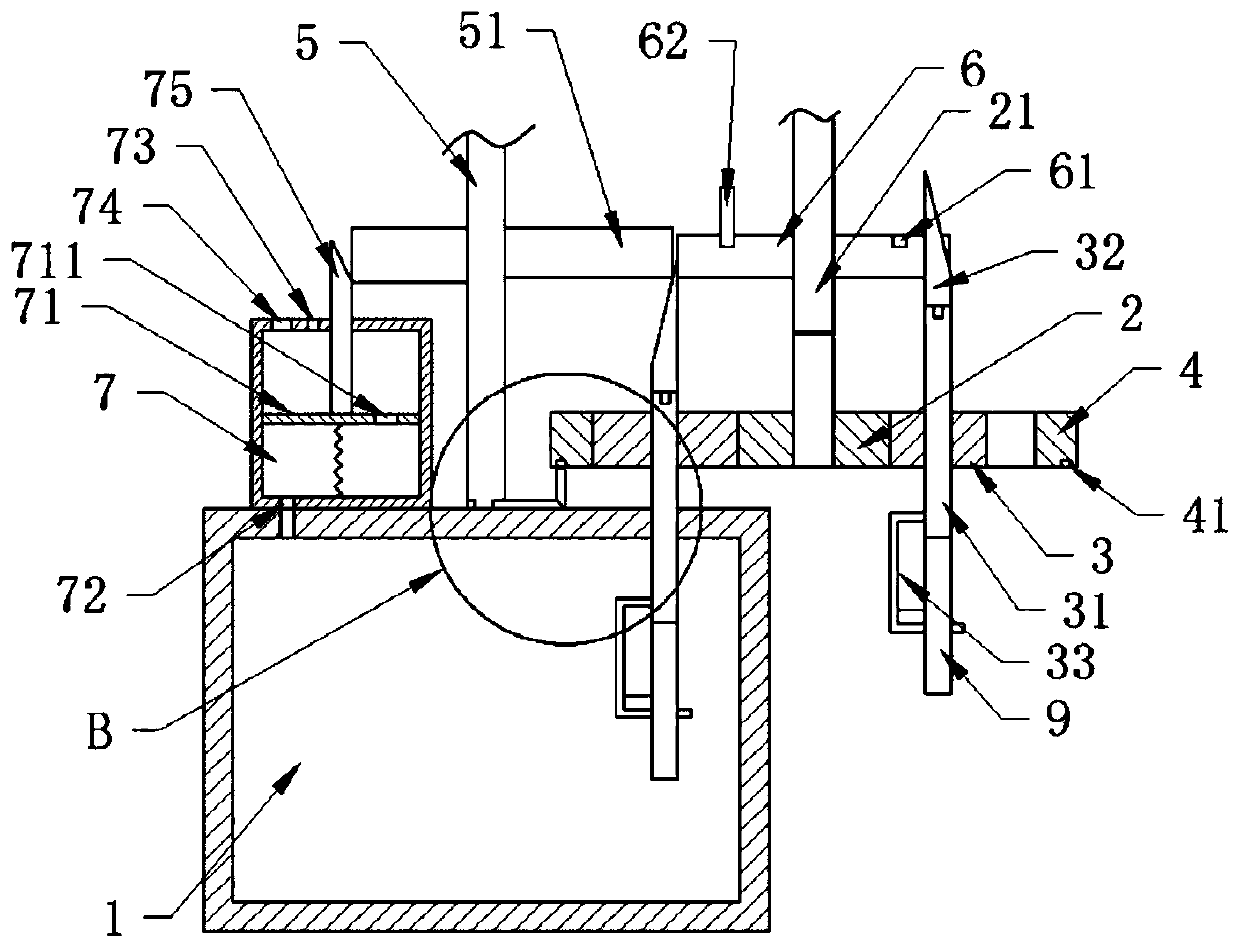

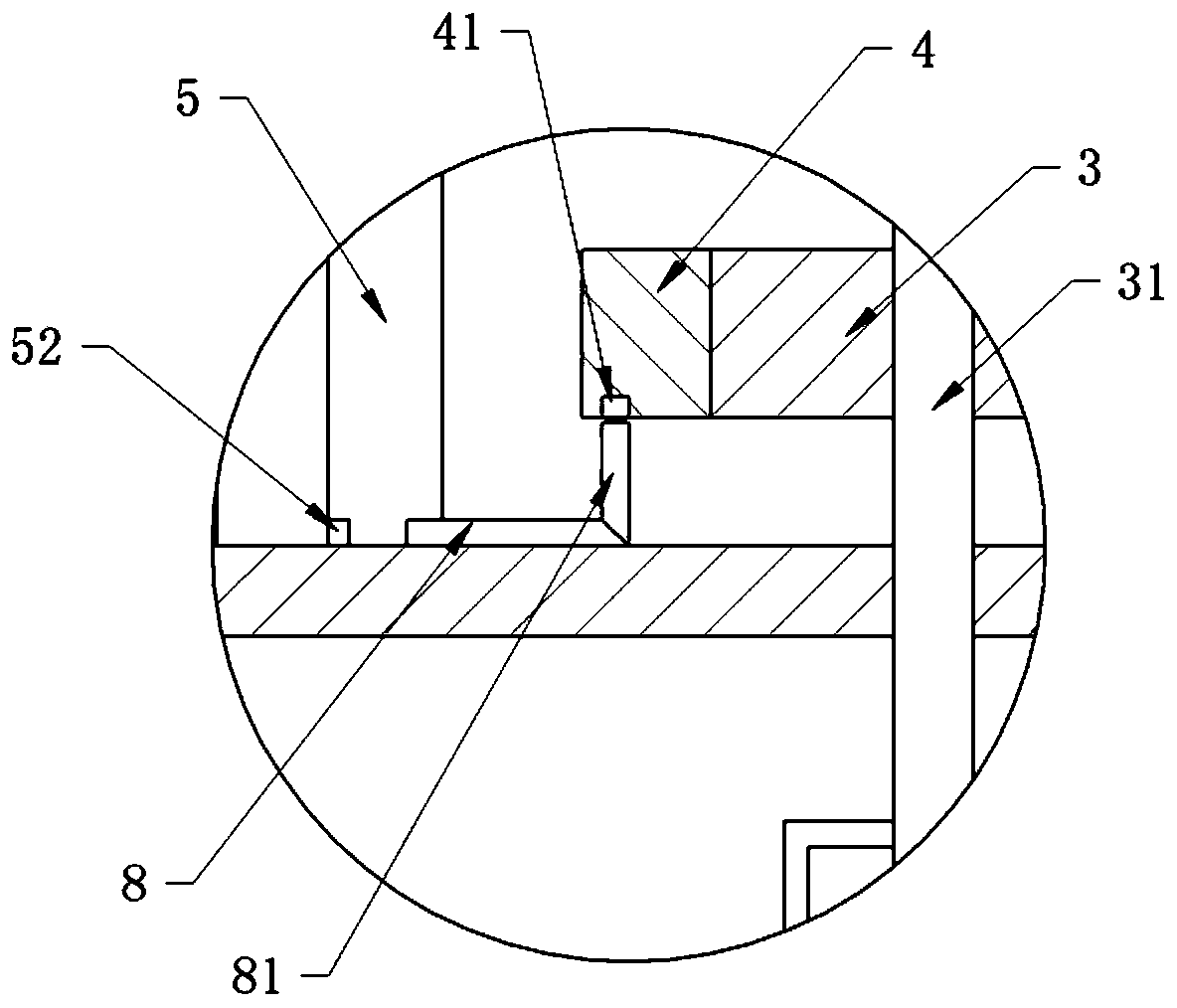

[0027] The reference signs in the accompanying drawings of the description include: cooling box 1, arc-shaped hole 11, bar-shaped hole 12, driving gear 2, rotating shaft 21, driven gear 3, transmission shaft 31, moving block 32, mounting frame 33, internal gear Ring 4, first locking port 41, rotating shaft 5, cam 51, sliding groove 52, planet carrier 6, second locking port 61, locking lever 62, smoke removal barrel 7, slide plate 71, smoke guide port 711, smoke inlet 72, water inlet 73, water outlet 74, push rod 75, first wedge bar 8, second wedge bar 81, workpiece 9.

[0028] The embodiment is basically as attached figure 1 Shown:

[0029] The high-frequency quenching equipment includes a frame and a cooling box 1 fixed on the frame. A planetary gear train is arranged on the right side of the cooling box 1 on the frame. Gear 2, ring gear 4 and five driven gears 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com