A method for detection and classification of internal toothed steel wheels in harmonic reducers

A technology of harmonic reducer and classification method, applied in sorting and other directions, can solve the problems of human judgment error, resource waste cost, loss, etc., to avoid deformation, prolong service life, and ensure the effect of transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

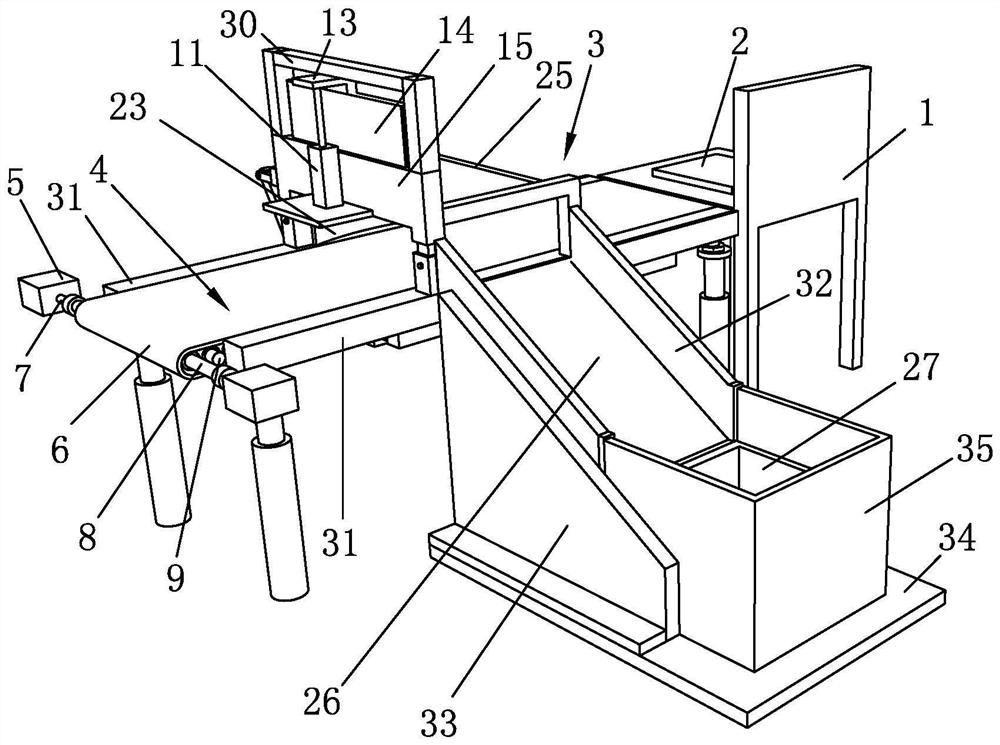

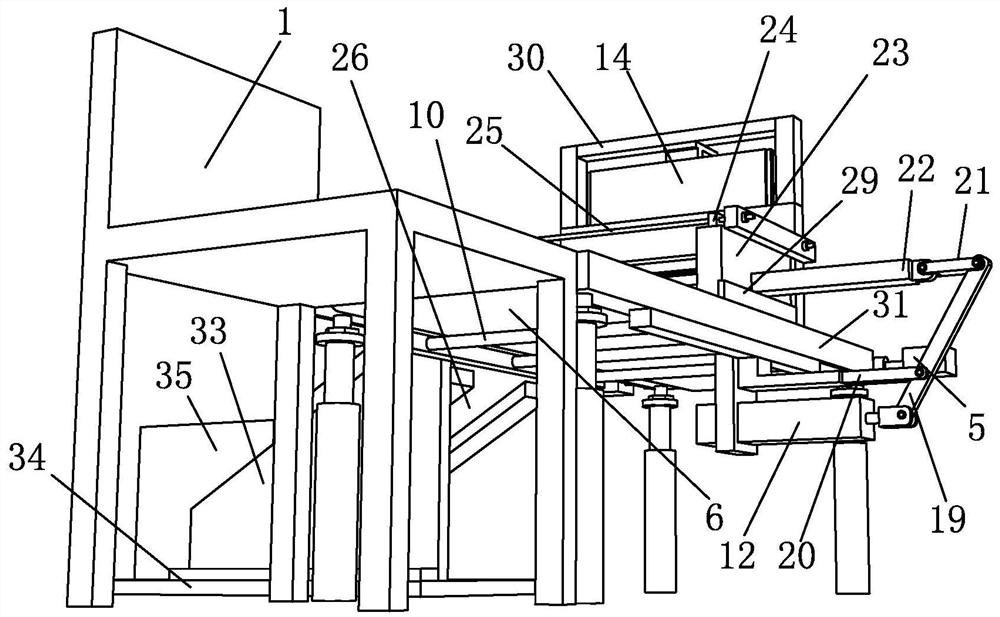

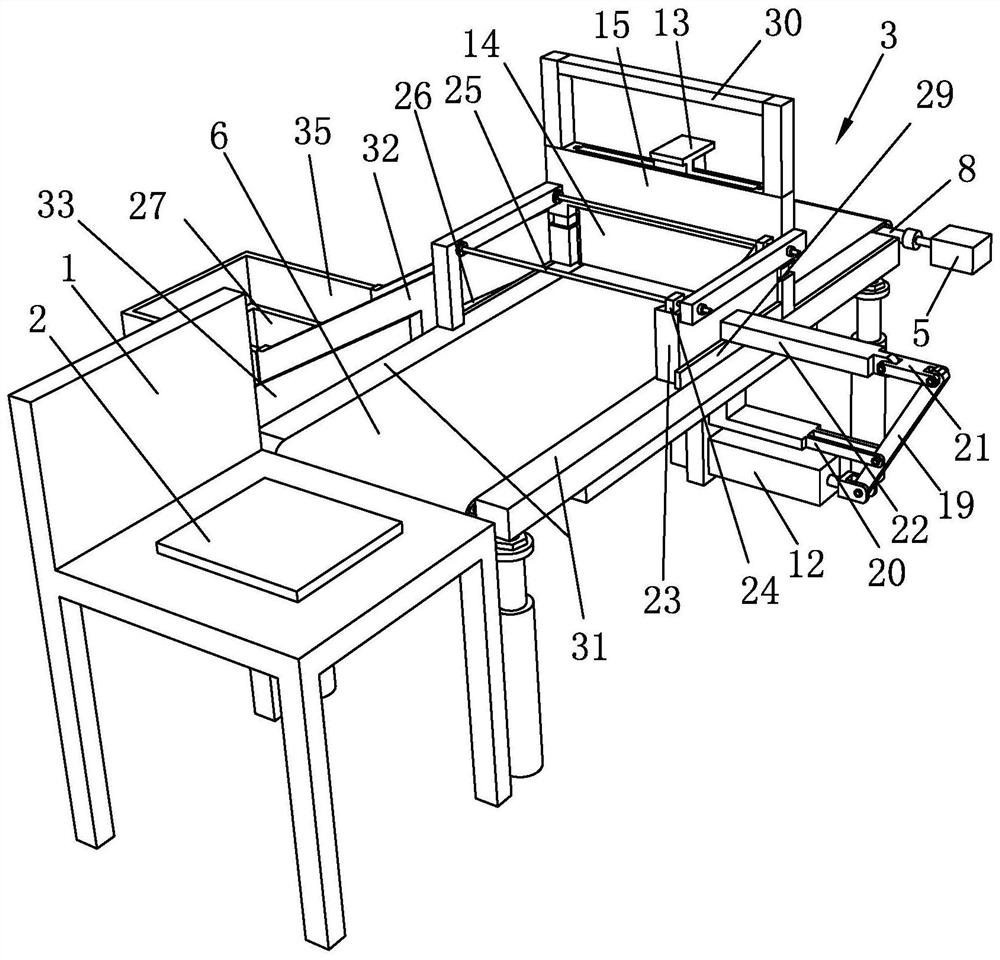

[0034] Such as Figure 1 to Figure 6 As shown, it is a method for detecting and classifying internal-toothed steel gear products in a harmonic reducer of the present invention, which includes the following steps:

[0035] 1) Product testing:

[0036] Put the product to be tested on the detection plate 2 of the detection platform 1, and use the detection device to detect the surface flatness, product diameter and internal tooth size of the product;

[0037] 2) Product classification:

[0038] a. Before product classification, the height of the limit frame 15 must be adjusted according to the actual height of the product to ensure that qualified products pass through the conveyor belt 6 and are transported to the next process through the slot below the limit frame 15. Position screw 38, adjust the length of the insertion rod 36 at the bottom of the limit frame 15 inserted into the fixed frame 37, until the height of the through groove is not less than the height of the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com