Linear rotary compound feeding robot

A robot and feeding technology, applied in the direction of manipulators, electromechanical devices, electric components, etc., can solve the problems of large occupied space, high manufacturing cost, and high failure rate, so as to reduce equipment failure rate, eliminate connecting parts, and reduce X-axis. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

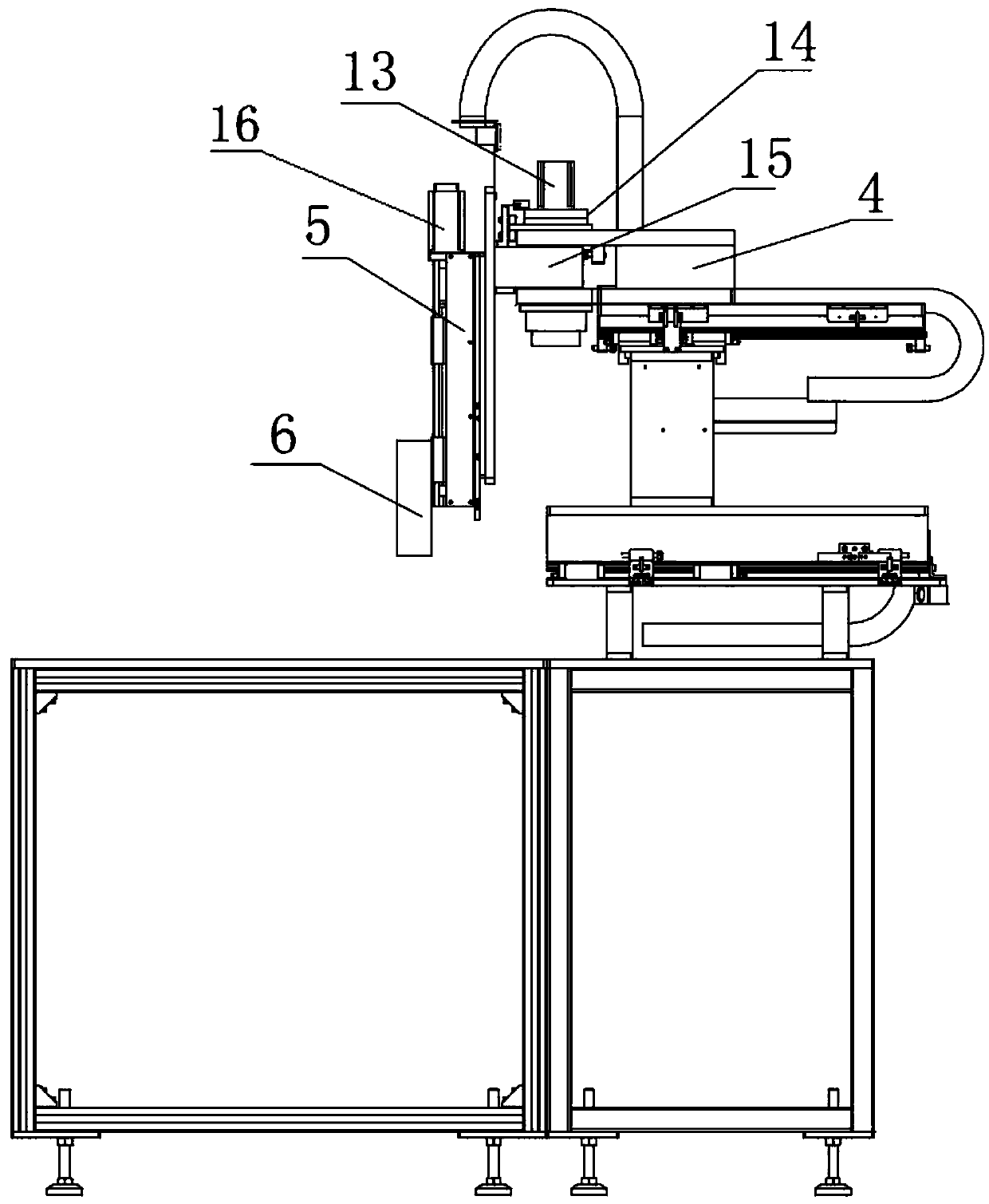

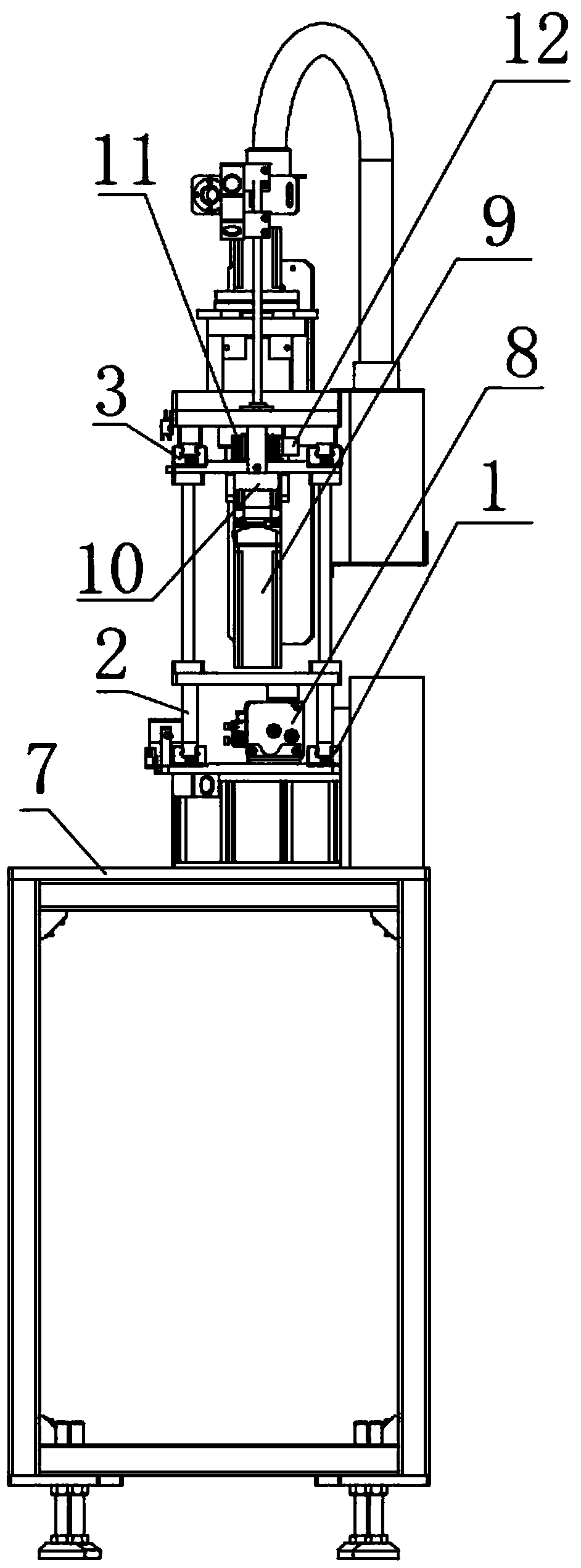

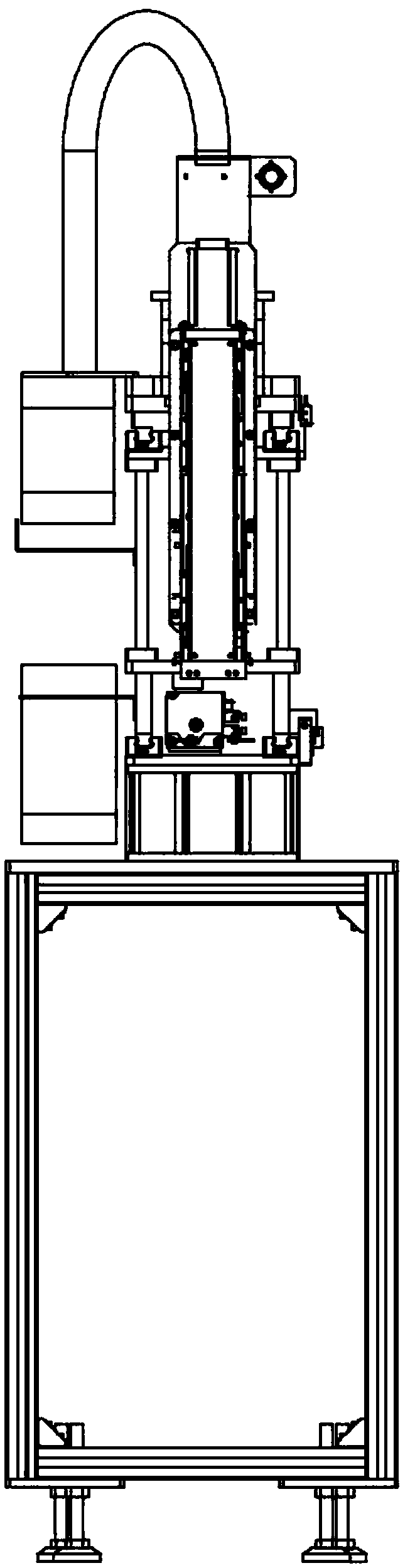

[0019] Attached below Figure 1-4 The present invention is described further:

[0020] A linear and rotary compound feed robot, including a Y-axis guide rail a1 fixed on the workbench 7, on which the Y-axis guide rail a1 is slidably connected to a carriage 2, and the carriage 2 is driven on the Y-axis guide rail a1 by the cylinder 8 at the bottom Moving upward, the cylinder 8 is connected to the control system, the carriage 2 is fixed with a Y-axis guide rail b3, and the Y-axis guide rail b3 is slidably connected to the sliding seat 4, and the bottom of the Y-axis guide rail b3 is provided with a servo motor a9. The servo motor a9 is connected to the drive shaft through the reducer 10, the outer periphery of the drive shaft is provided with a gear 11, the gear 11 meshes with the rack 12 fixed on the carriage 2, the servo motor a9 is connected to the control system, and the slide seat 4 is connected in rotation The Z-axis guide rail 5, the end of the sliding seat 4 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com