a labeling machine

A label machine and label paper technology, applied in the field of label machines, can solve the problems of wasting manpower and energy, and achieve the effect of ensuring quality and reducing the trouble of reciprocating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

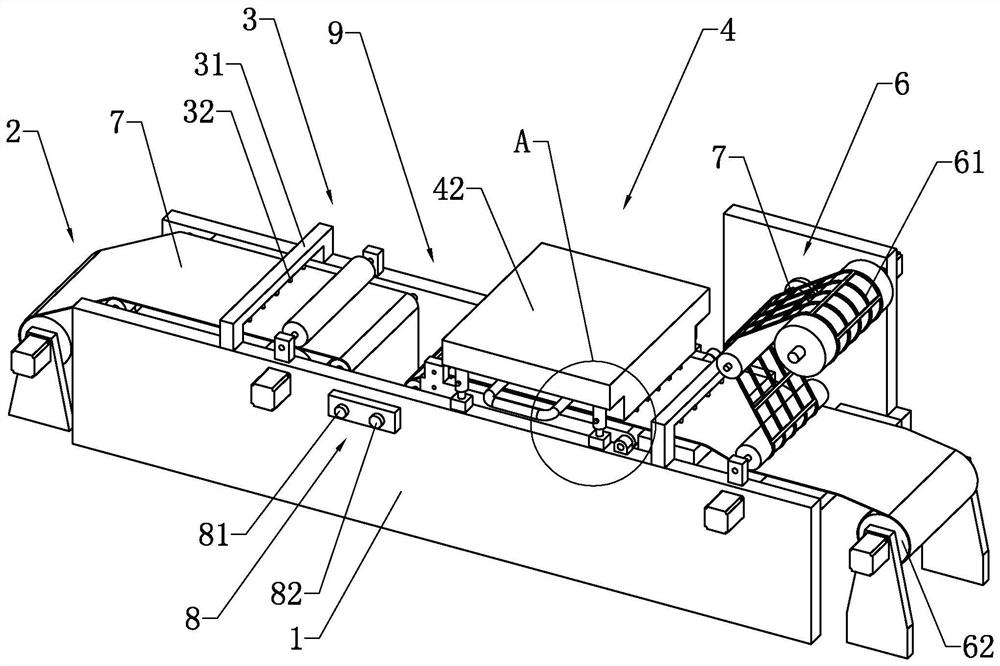

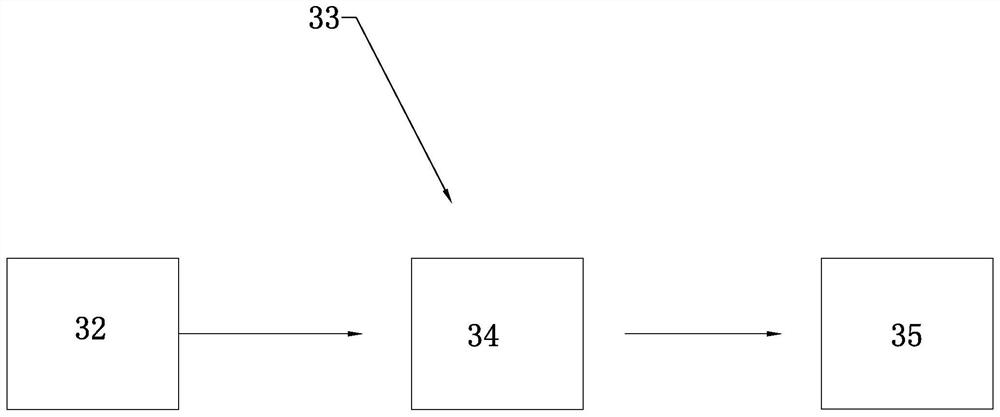

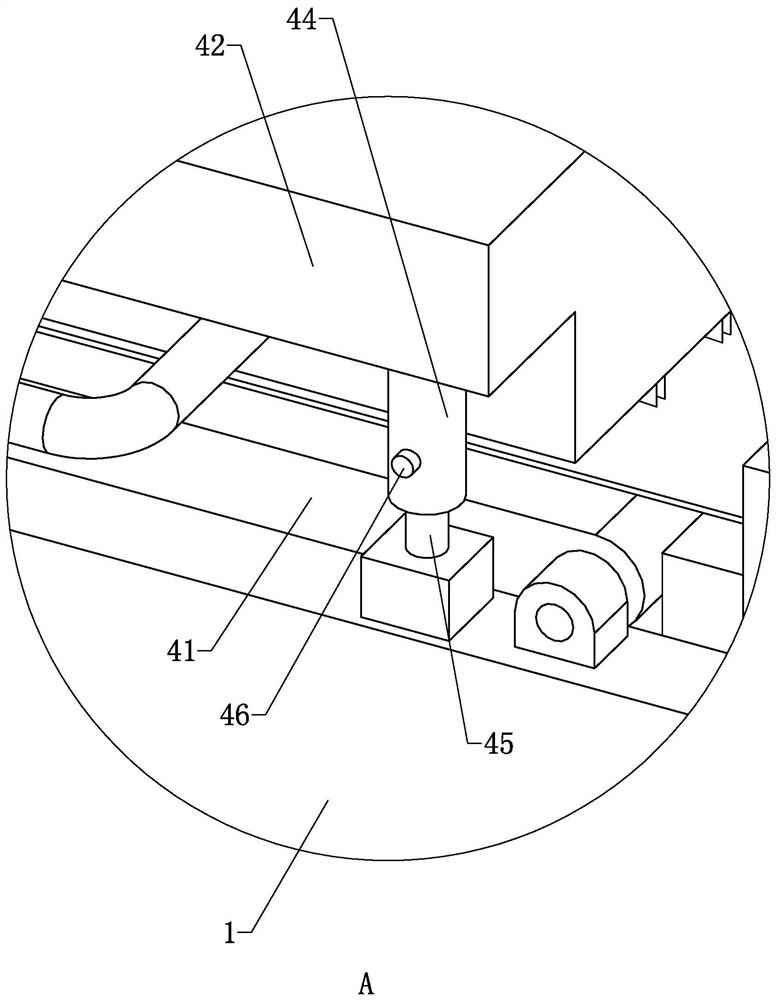

[0042] Embodiment: a kind of labeling machine, as figure 1 As shown, it includes a frame 1, a paper feeding device 2 connected to one end of the frame 1, a first detection device 3 connected to the frame 1 and detecting the printing situation of the label paper 7, and a work station next to the first detection device 3. The die-cutting device 4 at the first station, the second detection device 5 located at the next station of the die-cutting device 4 and detecting the die-cutting of the label paper 7, and the second detection device 5 located at the next station to tear the label paper 7 The finished product unwinding device 6, the alarm device 8 that is coupled to the first detection device 3 and the second detection device 5 and sends out an alarm according to the detection results, wherein the label paper 7 is limited by a plurality of rotating rollers connected to the frame 1 bits and drivers.

[0043]When in use, the paper feeding device 2 can be directly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com