Lifting system of pneumatic motor with excellent operating conditions

A technology of air motor and lifting system, which is applied in the direction of lifting devices, etc., and can solve problems such as operation compatibility constraints, inability to lift devices to the correct target location, failure to meet operating specifications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in connection with the drawings and embodiments.

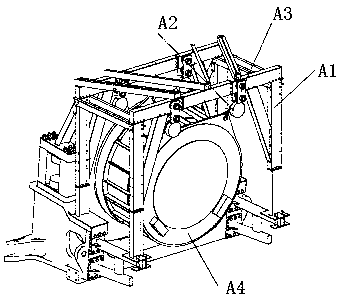

[0025] Such as Figure 1-Figure 3 As shown, the lifting system of the air motor in good operating condition is used to lift the equipment to be lifted A4 in the air motor accommodating cavity. The lifting system has a lifting frame A1 and a lifting device A2, and the lifting device A2 is a crank;

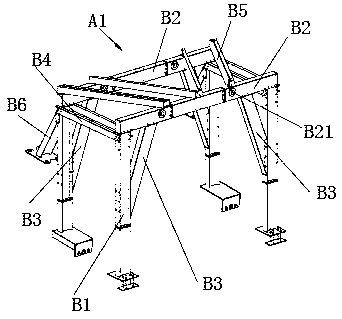

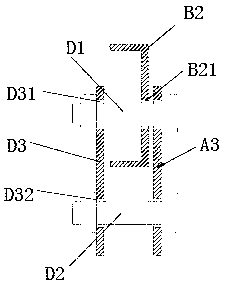

[0026] The lifting frame A1 has a lifting assembly, and there are more than one lifting assembly. Here, the lifting assembly has a vertical rod B1 and a horizontal rod B2. The number of the vertical rods B1 is a pair, and the pair of vertical rods B1 are arranged longitudinally and can Disassembled and arranged in the lower part of the air motor containing chamber, the two ends of the horizontal rod B2 can be disassembled and connected to the upper wall of a pair of vertical rods B1, and the lifting facility A2 can be disassembled and connected to the horizontal rod B2;

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com