Construction method for secondary lining at abrupt change section and dismantling method for temporary support of secondary lining at abrupt change section

A technology of temporary support and construction method, applied in wellbore lining, earthwork drilling, tunnel lining, etc., can solve the problems of large demolition workload, unsolvable problems, difficult work, etc., to improve safety and economy, Satisfy the overall use demand, ensure the effect of safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

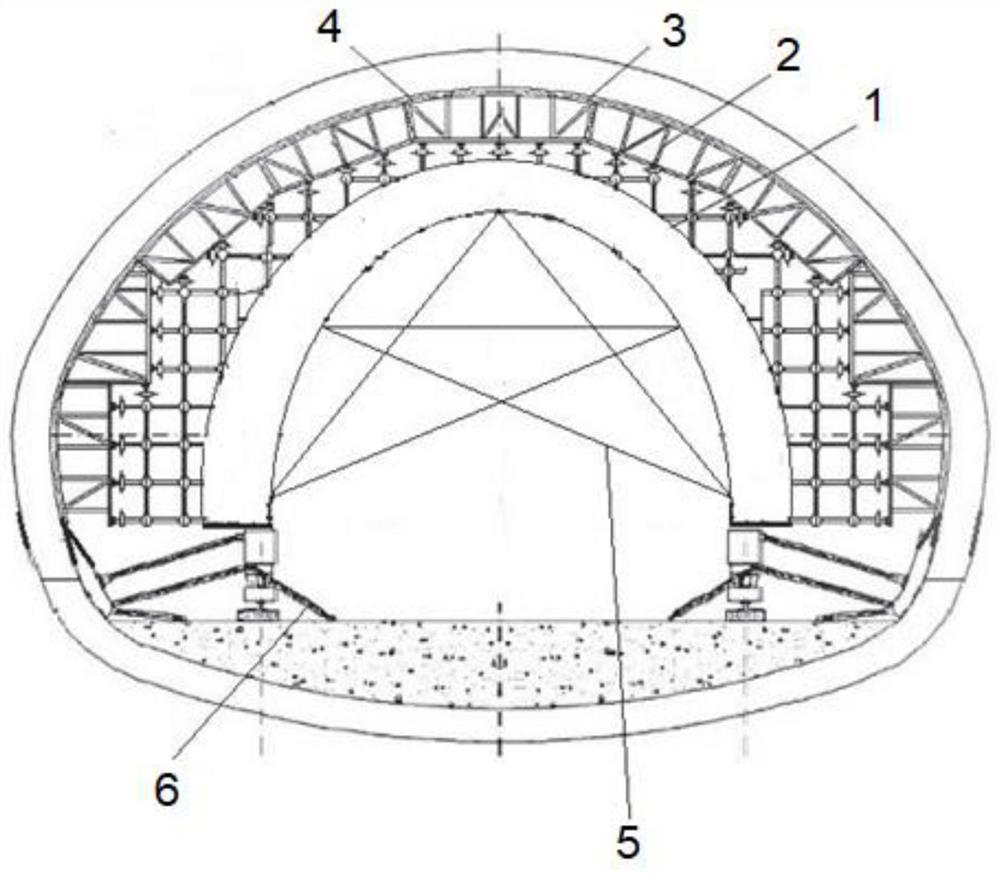

[0030] see figure 1 , a construction method for a secondary lining at a sudden change section and a method for dismantling its temporary support, comprising the following steps:

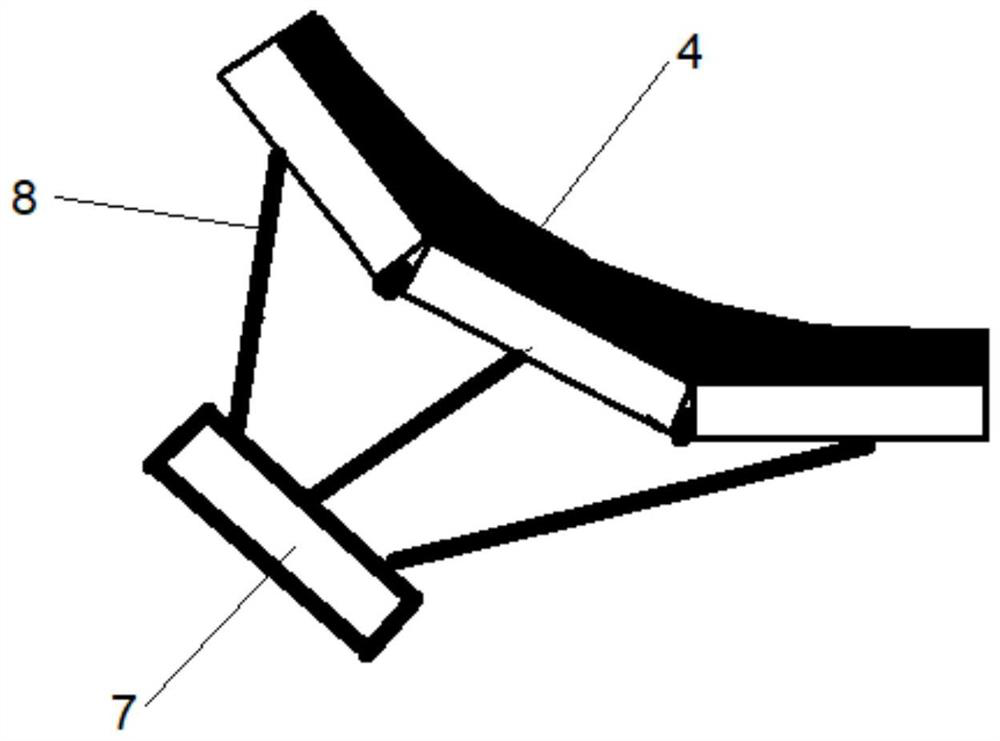

[0031] (1) After the initial support construction of the tunnel is completed and stabilized, start the secondary lining construction device to reach the designated construction position and then put it in place; the secondary lining construction device has an arched frame structure as a whole, and the inner side of the arched frame structure is provided with a support and stabilization system ;

[0032] (2) After the secondary lining construction device is in place, start the positioning device to make it stable at the construction position, and then start the secondary lining formwork system for jacking up the secondary lining construction device; the secondary lining formwork system is along the axial direction of the arched frame structure. Five are arranged side by side in sequence, and can be l...

Embodiment 2

[0045] see figure 1 , a construction method for a secondary lining at a sudden change section and a method for dismantling its temporary support, comprising the following steps:

[0046] (1) After the initial support construction of the tunnel is completed and stabilized, start the secondary lining construction device to reach the designated construction position and then put it in place; the secondary lining construction device has an arched frame structure as a whole, and the inner side of the arched frame structure is provided with a support and stabilization system ;

[0047] (2) After the secondary lining construction device is in place, start the positioning device to make it stable at the construction position, and then start the secondary lining formwork system for jacking up the secondary lining construction device; the secondary lining formwork system is along the axial direction of the arched frame structure. 6 are arranged side by side in sequence, and can be lift...

Embodiment 3

[0066] see figure 1 , a construction method for a secondary lining at a sudden change section and a method for dismantling its temporary support, comprising the following steps:

[0067] (1) After the initial support construction of the tunnel is completed and stabilized, start the secondary lining construction device to reach the designated construction position and then put it in place; the secondary lining construction device has an arched frame structure as a whole, and the inner side of the arched frame structure is provided with a support and stabilization system ;

[0068] (2) After the secondary lining construction device is in place, start the positioning device to make it stable at the construction position, and then start the secondary lining formwork system for jacking up the secondary lining construction device; the secondary lining formwork system is along the axial direction of the arched frame structure. Seven are arranged side by side in sequence, and can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com