A preparation method of ion exchange reinforced prestressed vitrified brick and its ceramic products

A technology of ion exchange and vitrified bricks, which is applied in the field of building ceramic materials, can solve problems such as the difficulty in meeting the needs of vitrified brick ceramic materials, and achieve the effects of saving high-quality ceramic raw material resources, preventing premature cracking and damage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

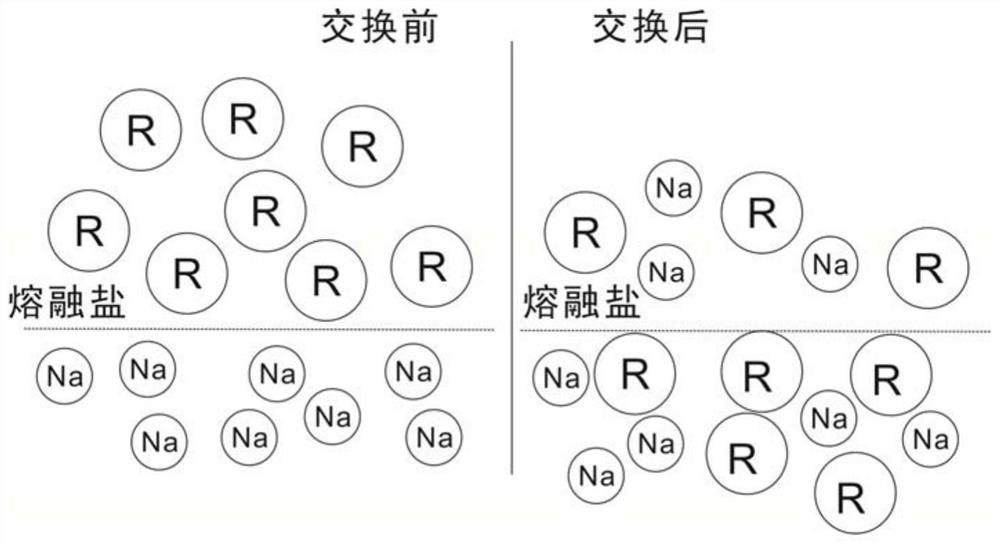

Method used

Image

Examples

Embodiment Construction

[0021] 1. The vitrified brick body of the embodiment of the present invention is composed of raw materials according to parts by weight: kaolin 30, quartz 30, albite feldspar 35, Datong sandstone 5. Its chemical composition is: SiO 2 65wt%, Al 2 o 3 20wt%, Fe 2 o 3 1wt%, (MgO+CaO)2wt%, Na 2 O 6wt%, K 2 O 1wt%, I.L 5wt%.

[0022] 2. The preparation method of the vitrified brick body in the embodiment of the present invention is as follows:

[0023] Mix the raw materials according to the above formula, crush the sample, wet ball mill, sieve to remove iron, dry at 90°C, add 6% water to granulate, and pass through a 60-mesh sieve to obtain powder; then the powder The material is made of metal film compact, the molding pressure is 15Mpa, the pressure is kept for 30s, and the vitrified brick body with length 100mm×width 20mm×thickness 6mm is obtained by pressing on one side.

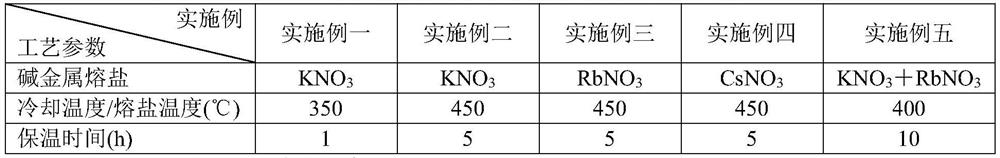

[0024] 3. The preparation method of the ion exchange reinforced prestressed vitrified brick accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com