Flexible prefabricated member and method for constructing pipe gallery by using flexible prefabricated member

A prefabricated and flexible technology, applied in construction, water conservancy projects, artificial islands, etc., can solve the problems of multiple and complex detailed structures, affecting the deformation function of deformation joints and waterproofing, so as to ensure the quality of molding, shorten the construction period, and eliminate The effect of leakage hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing and embodiment, and the explanation of this embodiment is only for better understanding the present invention, it should be emphasized that, for those of ordinary skill in the art, without carrying out creative work Under the premise, several improvements and adjustments can be made to the present invention, especially in terms of the size of the flexible preform and the materials used, and these improvements and adjustments are also protected by the claims of the present invention.

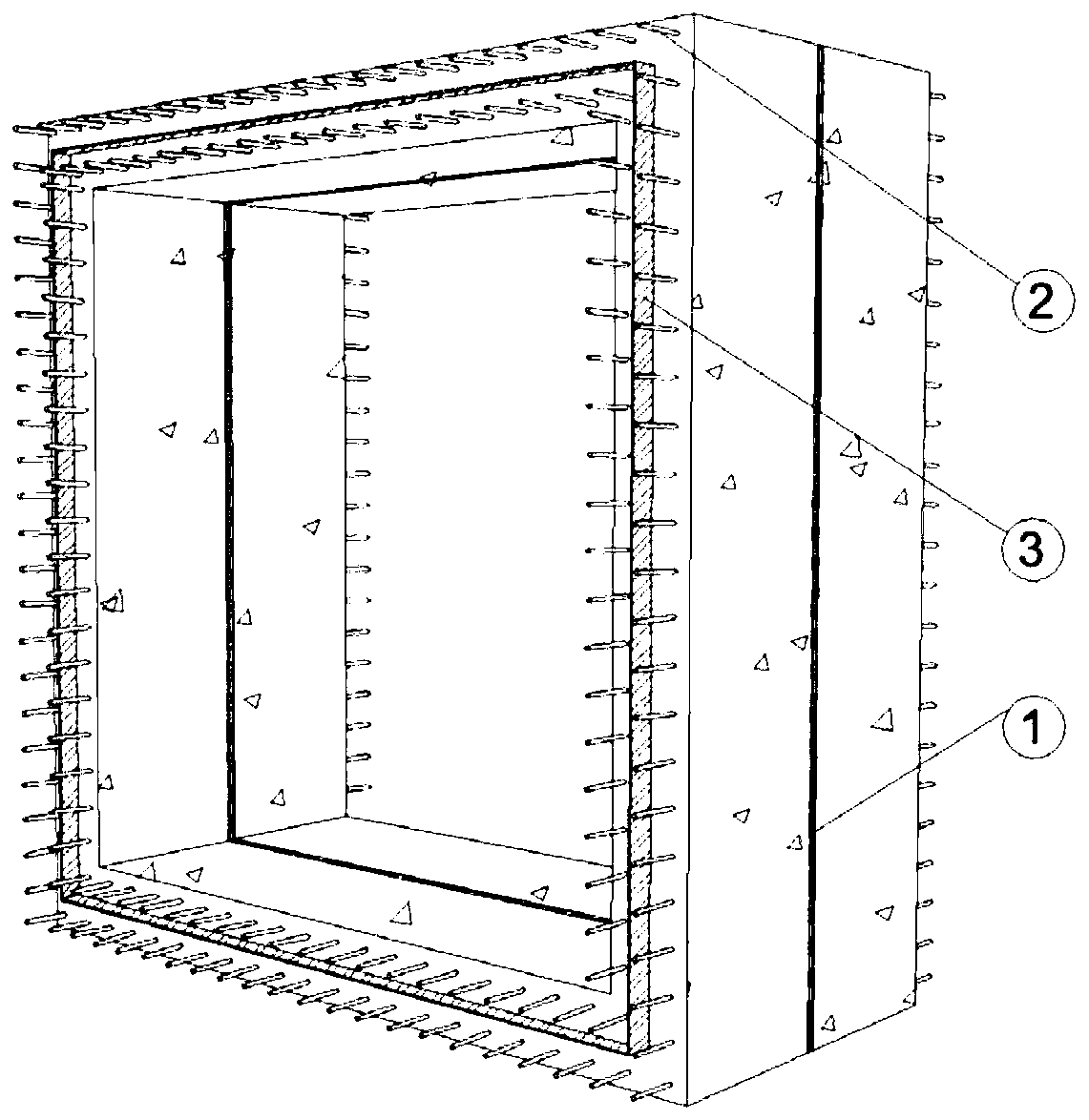

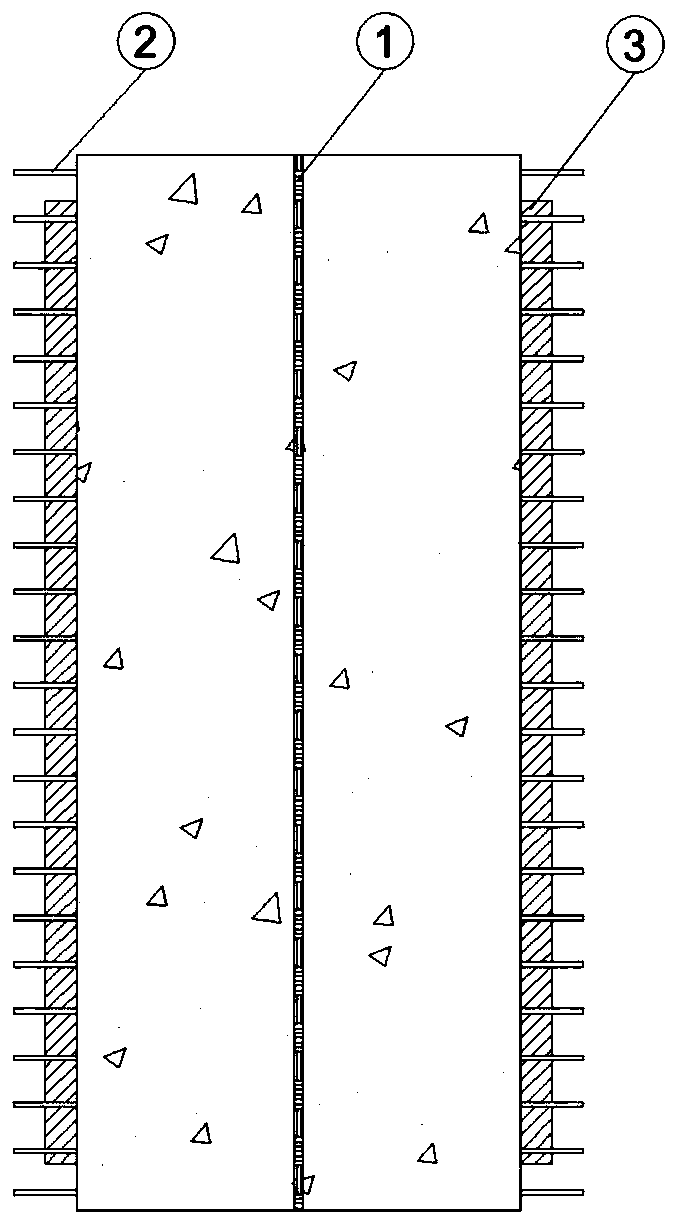

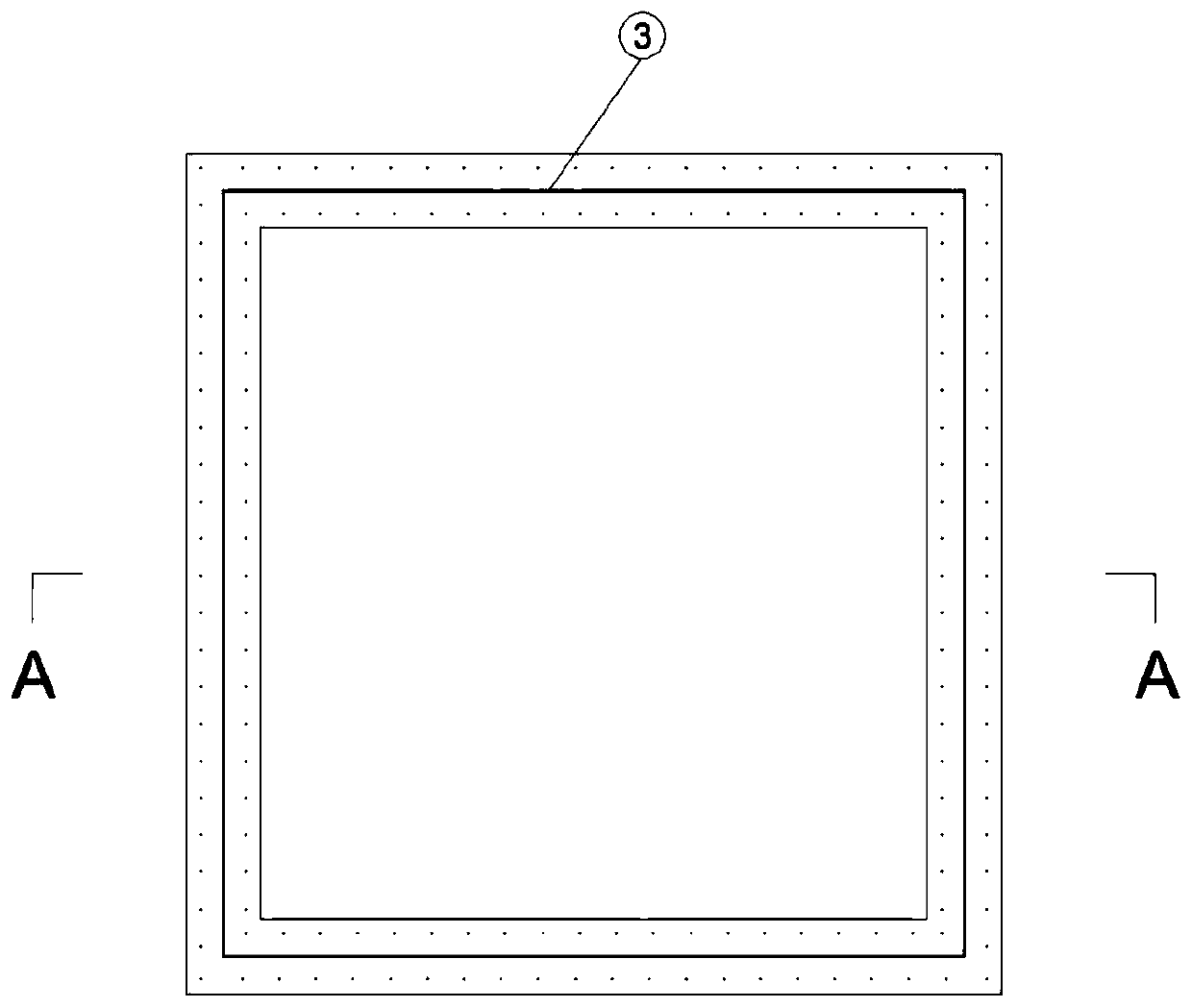

[0040] Such as Figure 1-5 As shown, according to the design requirements, a certain length of flexible prefabricated parts 10 including deformation joints are prefabricated in the prefabrication factory. Wherein the structural requirements of the flexible prefabricated part 10 are as follows:

[0041] The height, width and other cross-sectional dimensions of the flexible prefabricated part are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com