A component-based cable network process design system and method

A technology of process design and cable network, which is applied in the directions of instruments, calculations, and electrical digital data processing, etc., can solve the problems of heavy process repetitive workload and difficulty in direct reuse of design data, achieve convenient and correct filling, and improve electrical equipment. The effect of process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

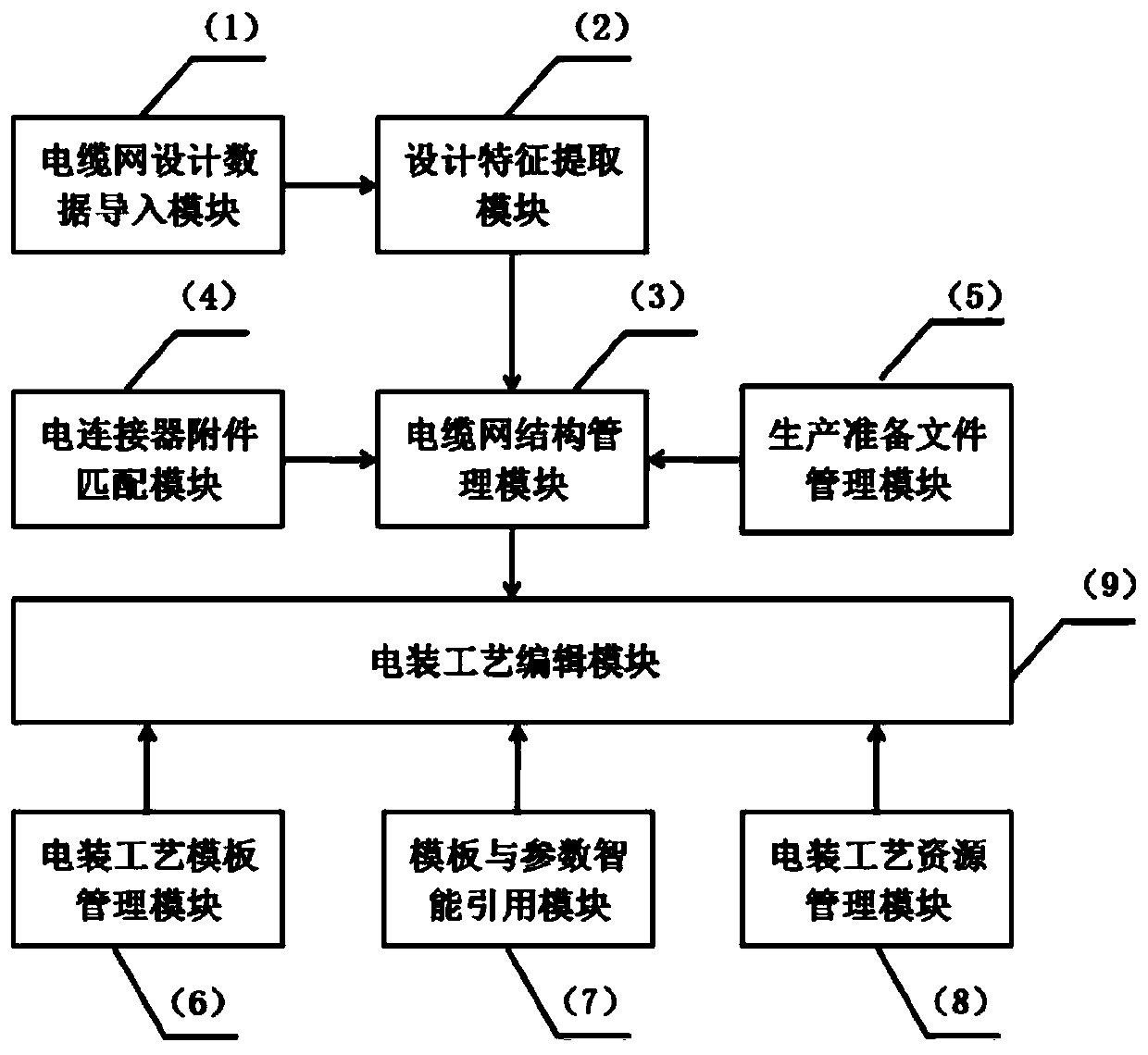

[0039] A cable network process design system based on the characteristics of components, the system includes: a cable network design data import module (1), a design feature extraction module (2), a cable network structure management module (3), and an electrical connector accessory matching module (4), production preparation document management module (5), Denso process template management module (6), template and parameter intelligent reference module (7), Denso process resource management module (8), Denso process editing module (9 ). As shown in Figure 1 of the accompanying drawing.

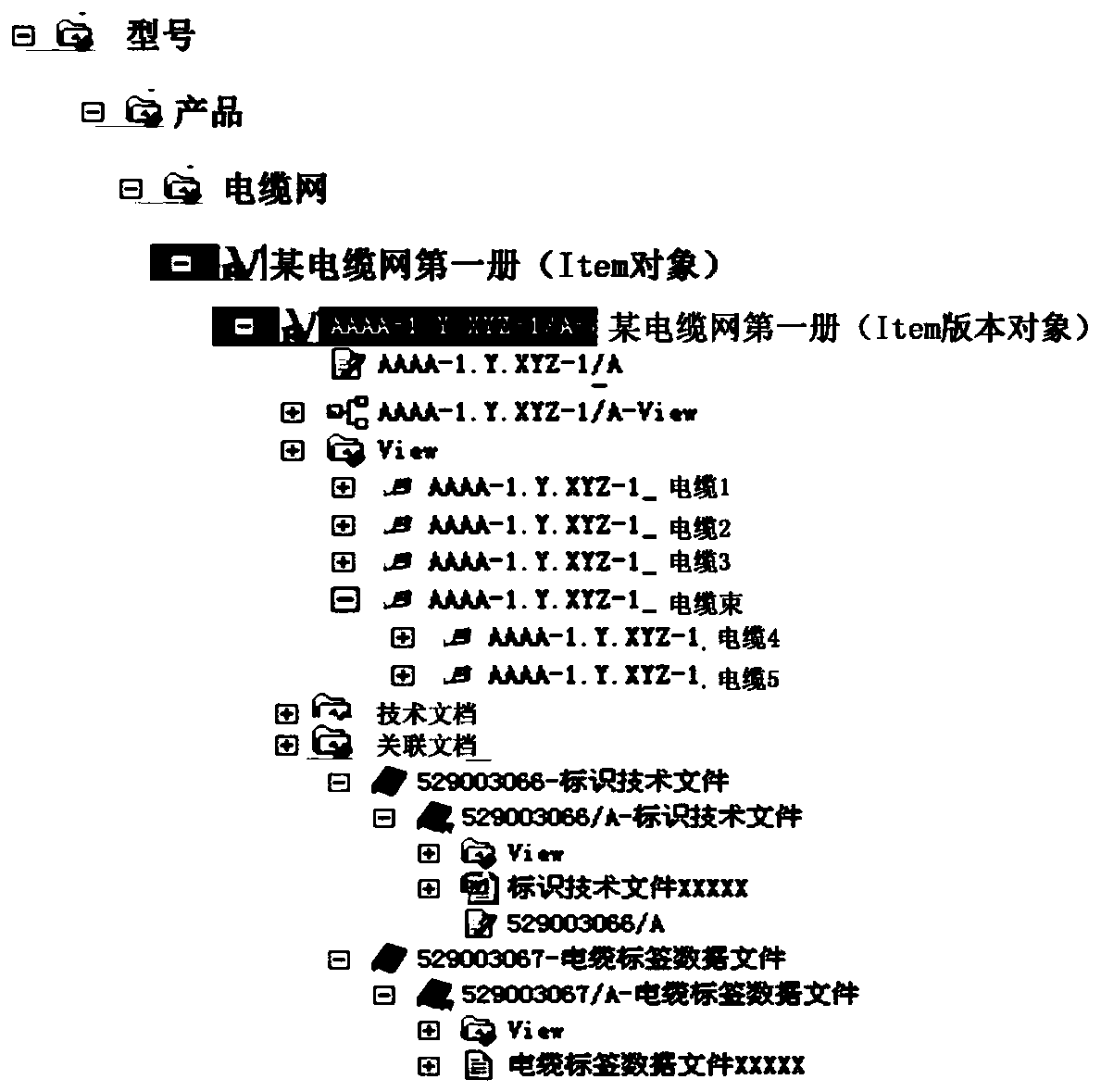

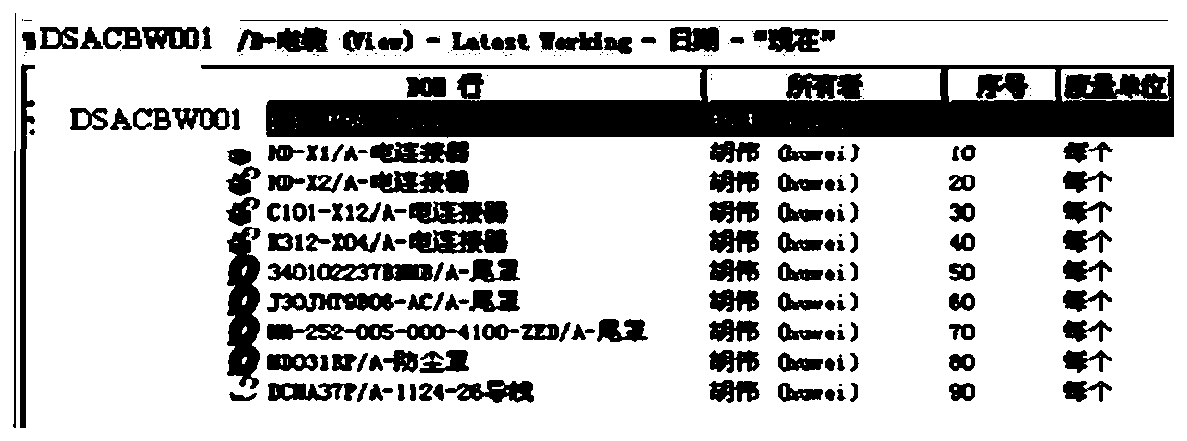

[0040] The first step is to use the cable network design data import module (1) to import the cable network structured design data table into the cable network process design system. The structured design data table of the cable network includes: a contact table, a supporting table of components, a branch relationship table, a branch length table, a cable length table, and a three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com