Water or aqueous solution based design method for metamaterial frequency selective surface

A frequency selective surface and design method technology, applied in the direction of electrical components, circuits, waveguide devices, etc., can solve the problems of long production cycle, insufficient performance, high cost, etc., and achieve easy processing and repair, simple preparation process, and production process The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

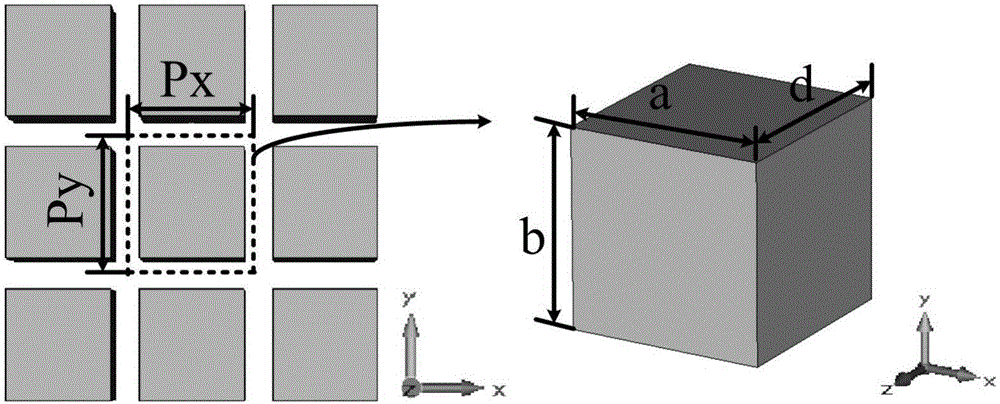

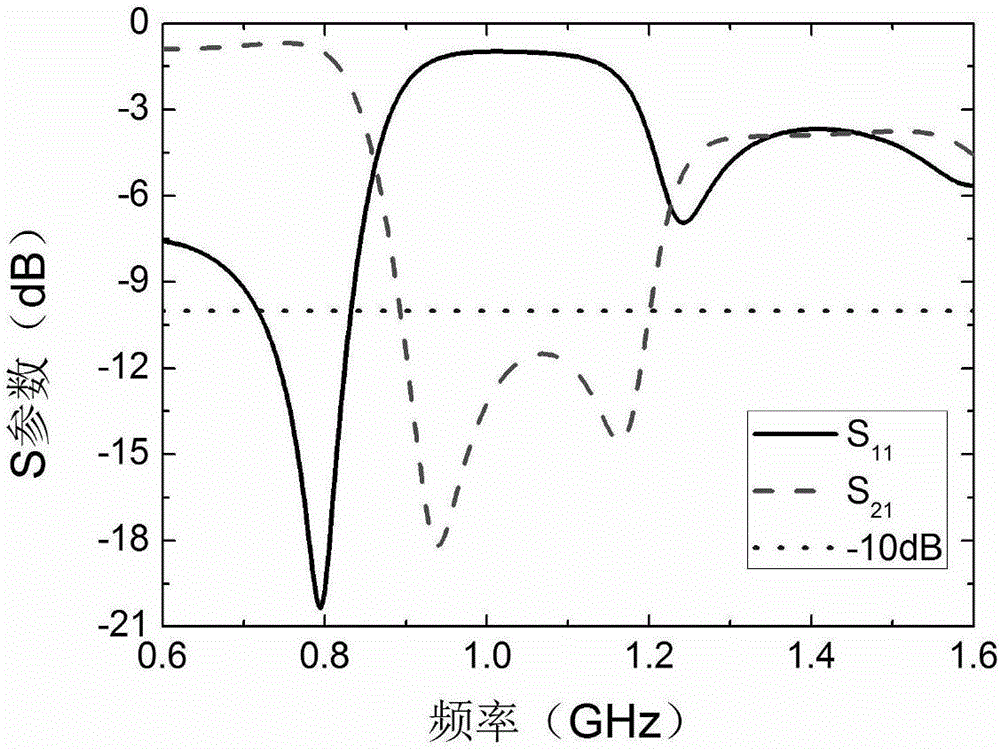

[0054] see figure 1 , This example uses a cubic array structure, a=28mm, b=28mm, d=35mm, Px=38mm, Py=38mm in the model diagram. see figure 2 , the working frequency band of the frequency selective surface stop band is 0.895-1.205GHz. The raw materials used include 3D printed photosensitive resin materials with low dielectric constant that have little effect on electromagnetic waves, and distilled water.

[0055] The preparation process for this example is:

[0056] (1) Test the dielectric constant and dielectric loss of distilled water at different temperatures and frequencies with a vector network analyzer and coaxial probe test accessories.

[0057] (2) Select appropriate temperature and structural parameters for the required working frequency band.

[0058] (3) This example is applied at a room temperature of 25°C, the frequency range is 0.6-1.6GHz, and the relative permittivity of water is about 78. Use electromagnetic simulation software for simulation calculations,...

example 2

[0063] see Figure 4 , This example uses a fishnet structure, a=16mm, b=20mm, d=9.6mm, Px=20mm, Py=20mm in the model diagram. see Figure 5 , the working frequency band of the frequency selective surface stop band is 0.56-1.56GHz. The raw materials used include 3D printed photosensitive resin materials with low dielectric constant that have little effect on electromagnetic waves, and distilled water.

[0064] The preparation process for this example is:

[0065] (1) Test the dielectric constant and dielectric loss of distilled water at different temperatures and frequencies with a vector network analyzer and coaxial probe test accessories.

[0066] (2) Select appropriate temperature and structural parameters for the required working frequency band.

[0067] (3) This example is applied at a room temperature of 25°C, the frequency range is 0.1-2.4GHz, and the relative permittivity of water is about 78. Use electromagnetic simulation software for simulation calculations, opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com