Double concave diamond energy transmission window and preparation process thereof

A diamond and double concave technology, applied in the field of double concave diamond energy transmission window and its preparation, can solve the problem of insufficient packaging strength, and achieve the effects of excellent effect, easy realization and improved transmission performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

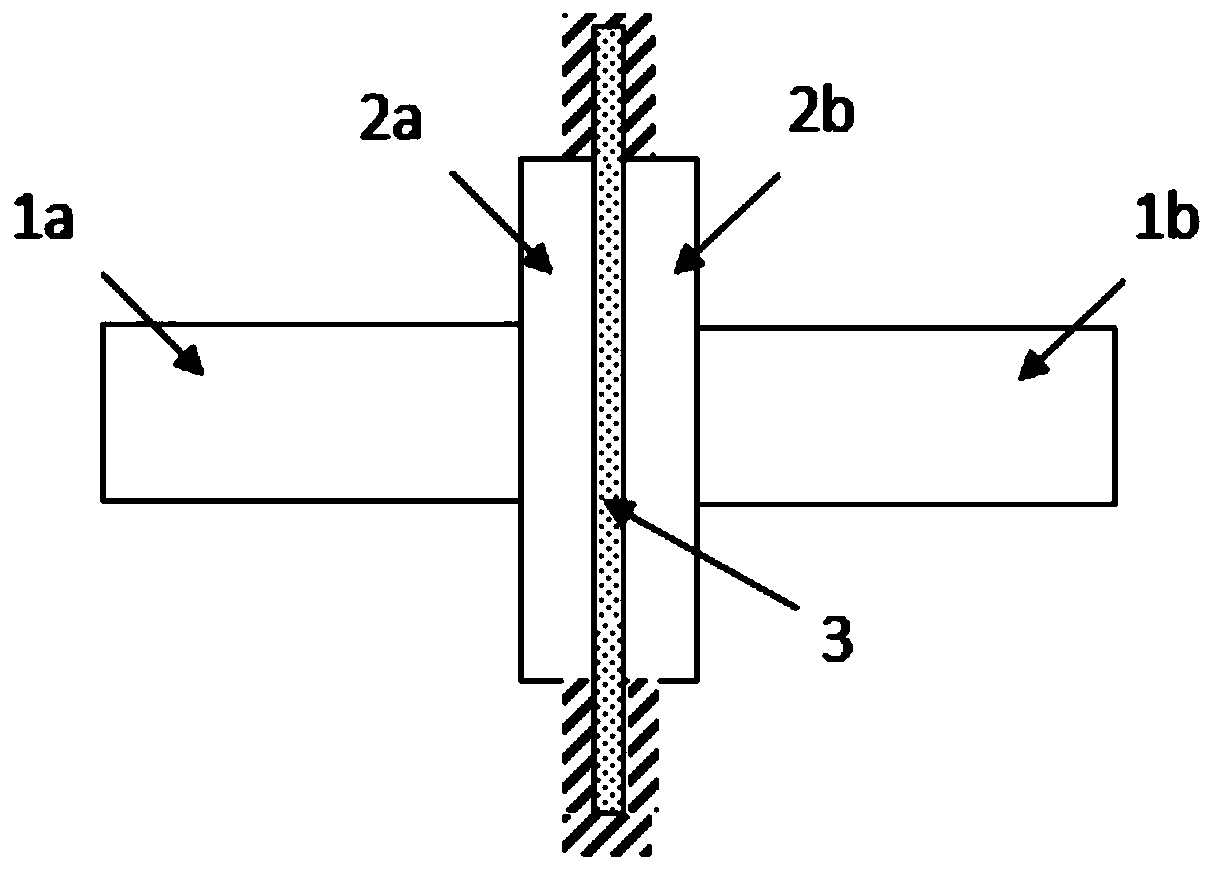

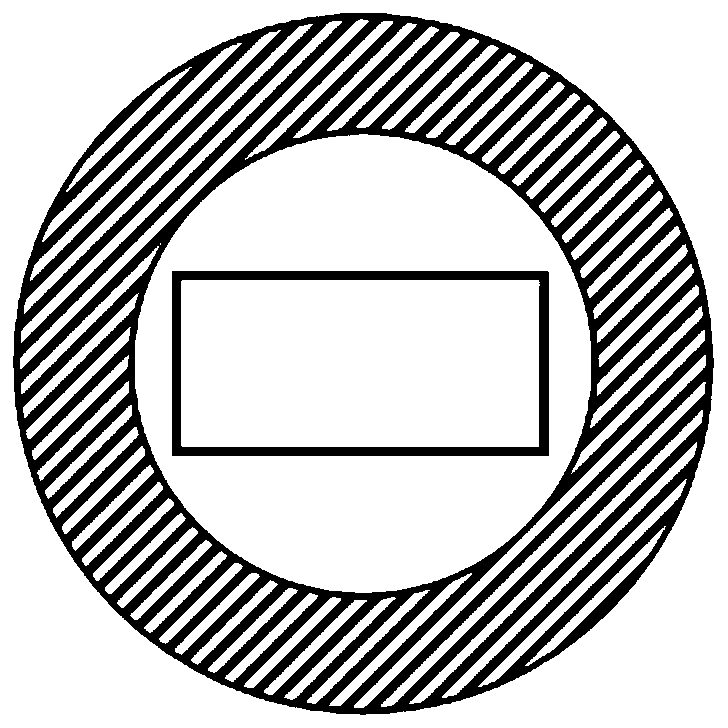

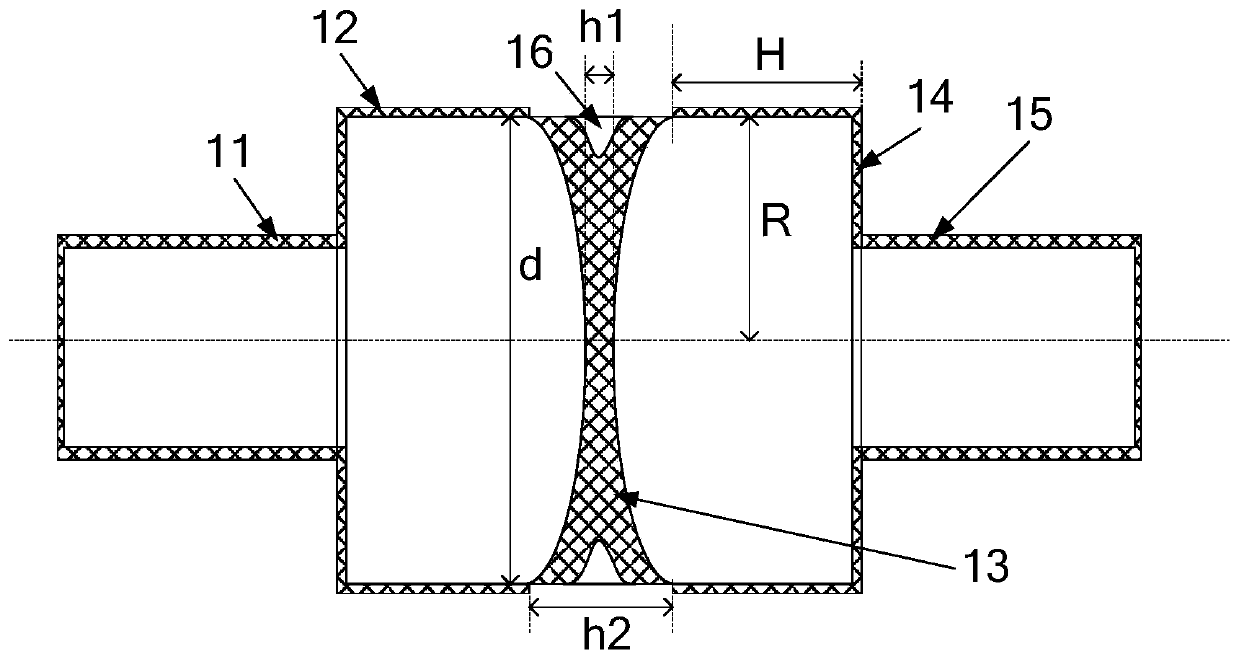

[0035] Double concave diamond energy transmission window, such as Figure 3-Figure 4 As shown, it mainly includes: a first rectangular waveguide 11 , a first circular waveguide 12 , a diamond window 13 , a second circular waveguide 14 and a second rectangular waveguide 15 . The diamond window 13 is a double-concave diamond window, which is sealed and welded in the middle of the first circular waveguide 12 and the second circular waveguide 14, and the first rectangular waveguide 11 and the second rectangular waveguide 15 are respectively welded on the first circular waveguide 12 and the second circular waveguide 14. The other side of the second circular waveguide 14. The energy transmission window metallization area described in the present invention is as image 3 The slashed part shown.

[0036] In this embodiment, the specifications of the first rectangular waveguide 11 and the second rectangular waveguide 15 are 2.54mm×1.27mm×3mm. The inner radius R of the first circular...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that the structure of the energy transmission window is optimized in this embodiment, such as image 3 As shown, the settings are as follows:

[0044] A groove 16 is arranged on the annular side of the diamond window 13 , and the groove 16 is an annular groove arranged along the annular side of the diamond window 13 . The cross-sectional shape of the annular groove can be various, such as semicircle, semiellipse, V-shape, V-like structure and the like. In this embodiment, the cross section of the groove 16 is preferably configured as a "V"-like structure, that is, a V-like shape composed of arc-shaped surfaces, such as image 3 shown. Since the groove 16 is arranged around the side of the diamond window 13, it can effectively function as a solder guide groove, reducing the risk of contamination of the window.

[0045] At the same time, during the preparation process, the shape of the inner wall of the semicir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com