Device for filling wafer with glass powder

A glass frit and wafer technology, applied in transportation and packaging, conveying bulk materials, semiconductor devices, etc., can solve the problems of affecting product production speed, low qualification rate of electronic components, and low brushing speed, so as to avoid glass frit Too much, to avoid the uneven distribution of glass powder, and the effect of fast brushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

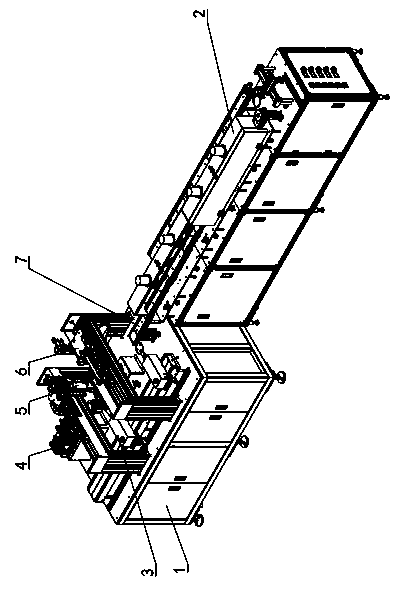

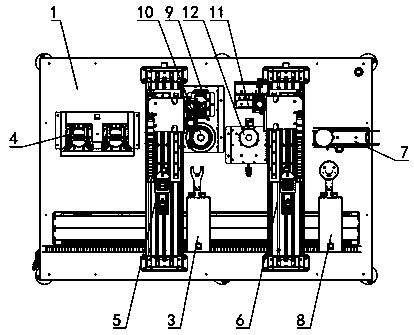

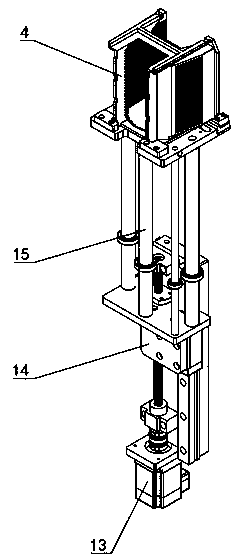

[0045] Figure 1~16 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~16 The present invention will be further described.

[0046]A device for filling glass powder into a wafer, including a supporting device for supporting the wafer, a feeding device 5 and a scraping device 6, and the feeding device 5 and the scraping device 6 are both arranged on the upper side of the supporting device , The lower side of the feeding device 5 is provided with a retrieving part and drives the reclaiming part to move, and the lower side of the scraping device 6 is equipped with a scraper 43 and drives the scraper 43 to move. The feeding device 5, which is a device for filling glass powder into the wafer, evenly places the glass powder on the wafer through the feeding part, and the scraping device 6 removes the excess glass powder on the wafer through the scraper 43, thereby ensuring that the wafer is filled with glass powder. The amount of glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com