Grinding wheel of coal mill

A coal mill and grinding wheel technology, applied in the field of coal mill grinding wheels, can solve the problems of large ventilation resistance, high grinding efficiency, small air-to-coal ratio, etc., to meet production needs, speed up grinding and pressing efficiency, and good extrusion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

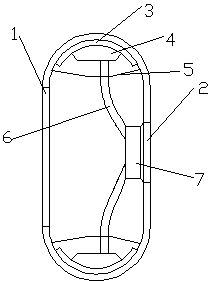

[0007] The figure shows an embodiment of the coal mill of the present invention, which includes a bowl-type grinding wheel, which is hollowly arranged. One side of the grinding wheel is provided with a grinding roller interface 1, and the other side is provided with an exhaust fan outlet 2. The inside bowl wall of the grinding wheel is Heating strips 3 are arranged on the top, and the heating strips are evenly distributed in a ring shape. The heating strips are connected to the heating machine 4. The heating strips and the heating machine are sealed and set by the sealing cover 5 provided outside. The air exhaust fan 7 that is provided with at the tuyere is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com