Tool setting method for annular mortise machining

A tongue-and-groove and ring technology, applied in the field of tool setting point selection, can solve problems such as unqualified machining dimensions, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: In this embodiment, the longitudinal direction is the X direction, and the horizontal direction is the Z direction. When setting the knife, it is the edge setting of the knife, that is, Z=0.

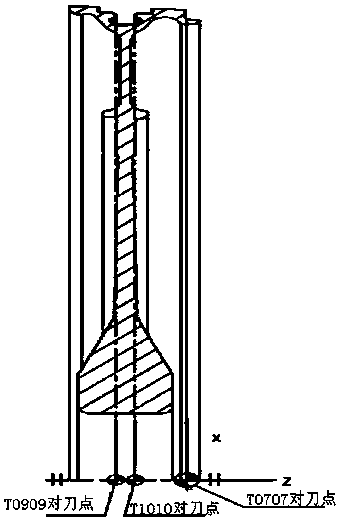

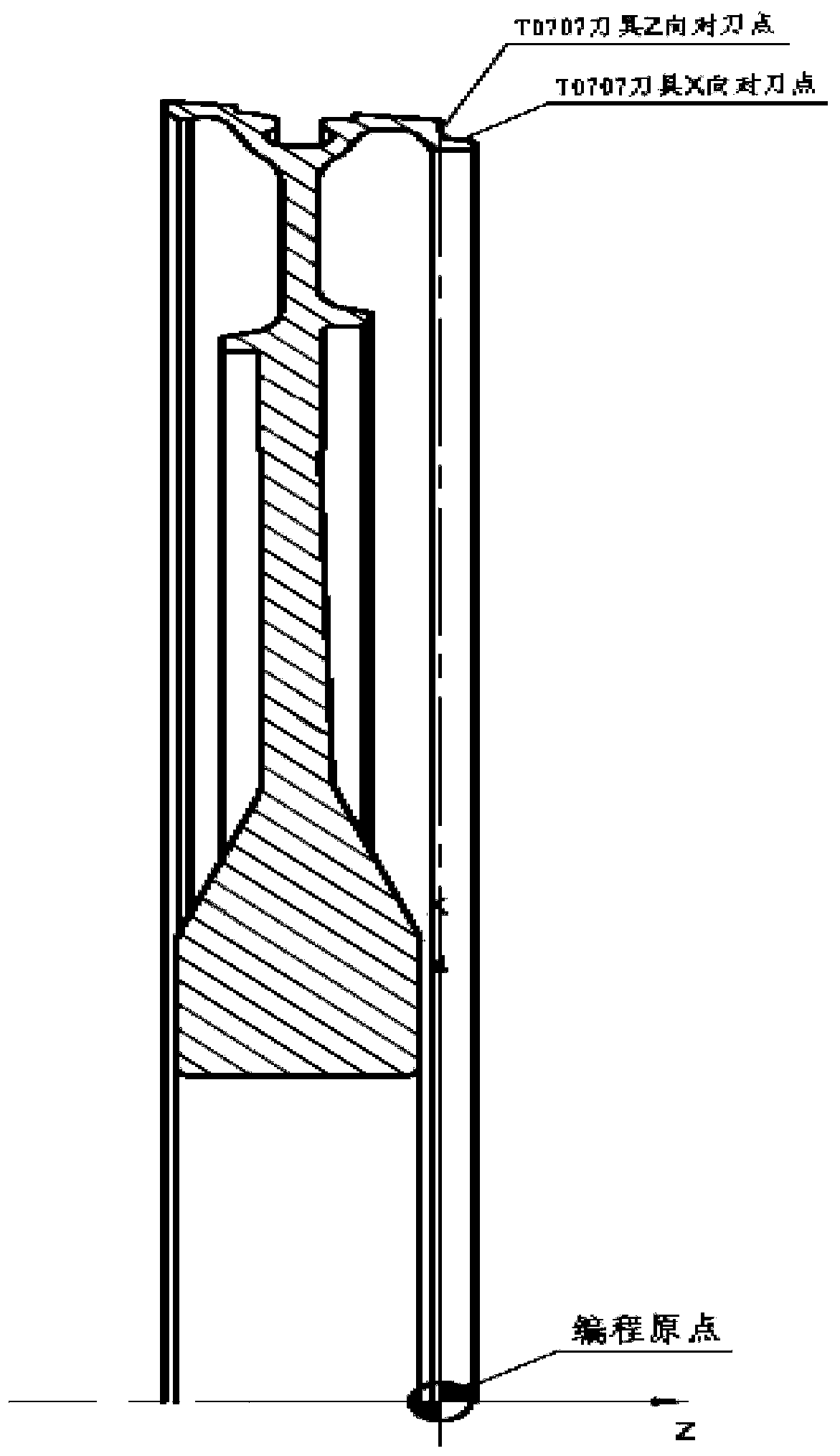

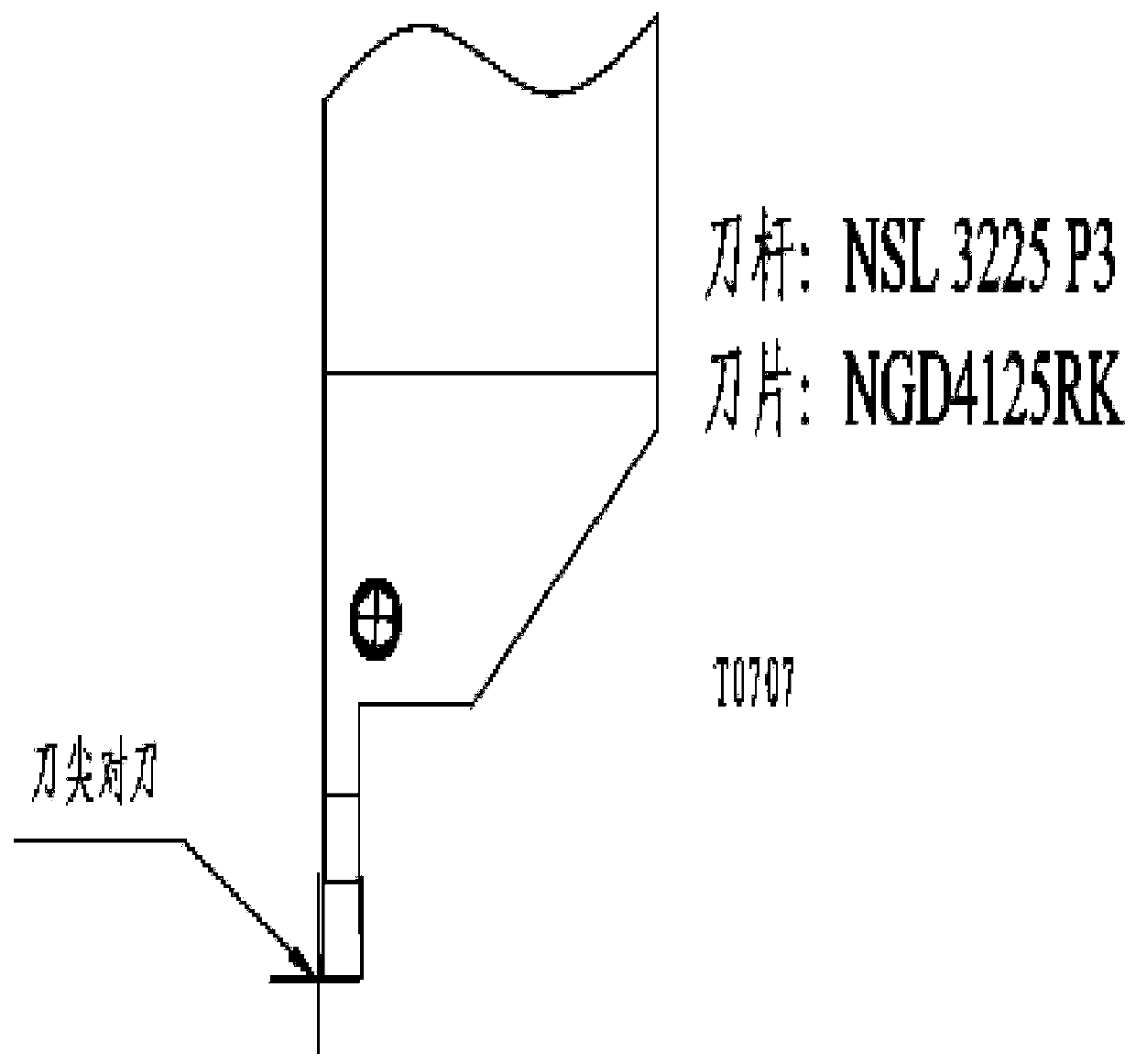

[0022] ①The tool setting point of the first straight tool (No. T0707 tool): X direction tool setting point, figure 1 Shown is straight OD. Z-direction tool setting point: the end face of the reference position of the part, such as figure 1 shown. figure 2 A schematic diagram of the tool. Selection of the first tool setting point: such as figure 1 As shown, because the slotting knife is the initial slotting (that is, ordinary outer circle slotting)

[0023] reason:

[0024] The normal initial grooving accuracy can be guaranteed with the accuracy of the end-to-knife. Therefore, the exposed straight mouth is selected as the X-direction tool-setting point for this tool-setting point, and the end face as shown in the figure is used as the Z-direction tool-setting poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com