Totally-enclosed linear guide rail unit

A linear guide rail, fully enclosed technology, applied in the direction of maintenance and safety accessories, large fixed members, metal processing machinery parts, etc., can solve the problems of reducing the service life of the guide rail, easy adhesion, affecting the lubrication effect of the guide rail, etc., to achieve extended use Long life, guaranteed lubrication effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

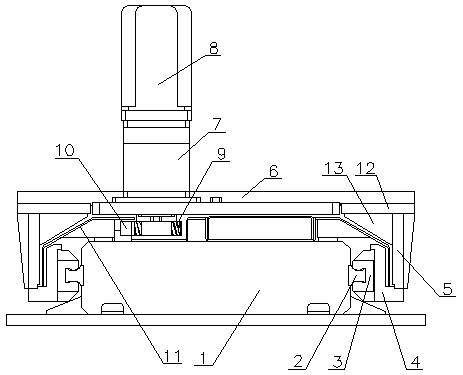

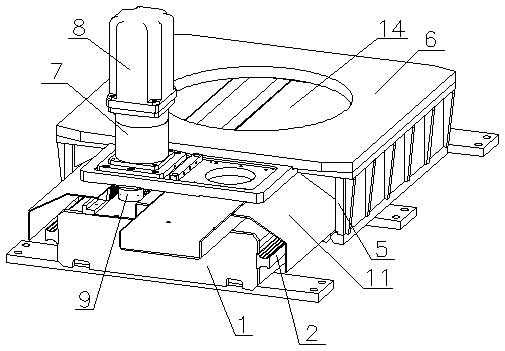

[0014] A fully enclosed linear guide rail unit, comprising a base 1, linear guide rails 2 are respectively provided on both sides of the base 1, a slider 3 is installed on the linear guide rail 2, the outer side of the slider 3 is fixedly connected to a supporting plate 4, the The supporting plate 4 is an L-shaped structure, the outer side of the supporting plate 4 is provided with a side plate 5, the lower end of the side plate 5 is fixedly connected with the foot of the supporting plate 4, the upper end of the side plate 5 is equipped with a slide plate 6, and the sliding plate 6 is provided with a There is a reduction motor 7, the upper end of the reduction motor 7 is provided with a servo motor 8, the output end of the reduction motor 7 is equipped with a gear 9, and the upper end surface of the base 1 is fixedly equipped with a rack 10 matched with the gear 9, the base A protective cover 11 is provided between 1 and the sliding plate 6, and the lower end of the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com