A kind of preparation method of ceramic glaze based on leaf

A technology of ceramic glazes and leaves, which is applied in the field of ceramic composite materials, can solve problems such as whether there are heavy metals left without careful research, can not meet food-grade standards, and endanger human health, etc., and achieve stable and reliable firing conditions and color rendering Improved stability and high cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the leaf-based ceramic glaze comprises the following steps:

[0033] (1) In the ball mill, according to the specific gravity of 1:0.7, put the components of the Konoha glaze and water into the ball mill for ball milling, specifically: add the following powders in the weight ratio: 21% SiO 2 , 11%P 2 o 3 , 0.2% Fe 2 o 3 , 12%Al 2 o 3 , 2%Cr 2 o 3 , 0.5% MnO, 8% MgO, 40% CaO, 5.6% K 2 O, and water; the ball in the ball milling tank can not exceed 1 / 2nd of the tank volume, and the ball milling time is about 30 minutes to ensure that the ball milling particles can pass through the 120 mesh screen to obtain the wood leaf glaze;

[0034] (2) Choose Longquan mud material, prepare a mud base with a thickness of 2-3mm, after low-temperature biscuit firing at 850°C, spray plum green glaze with a thickness of about 2mm, and then spray 1-2mm on the part of the glaze body (1 ) made of wood leaf glaze;

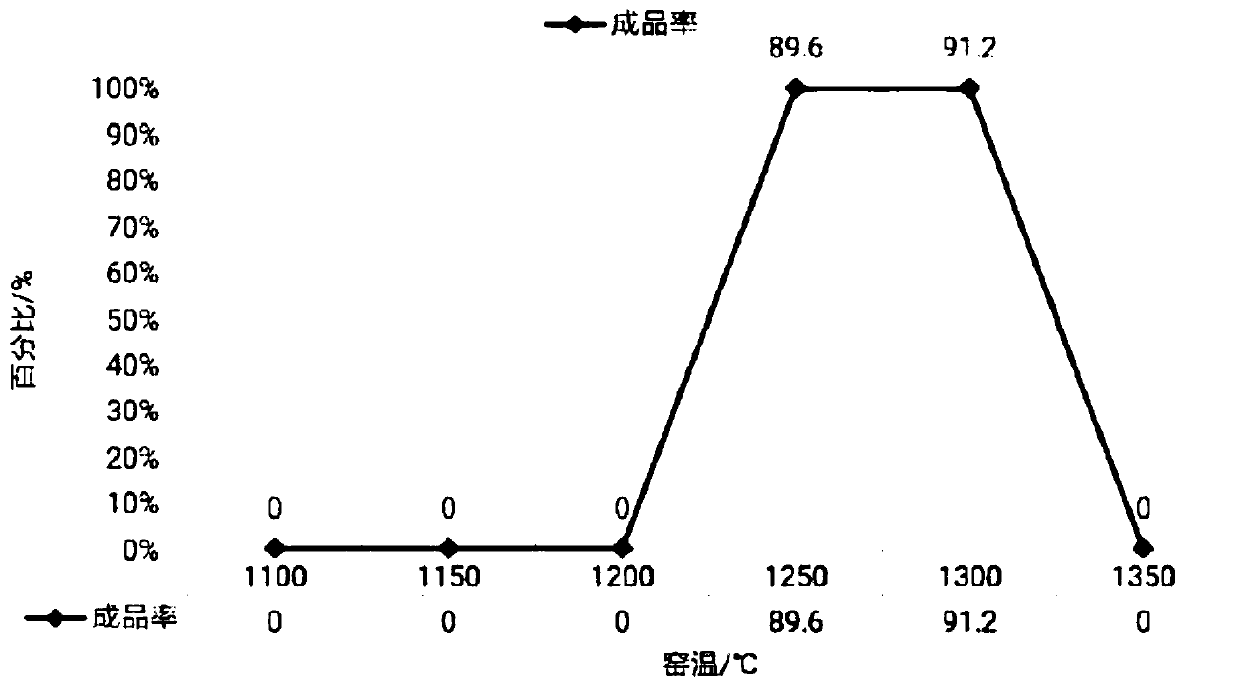

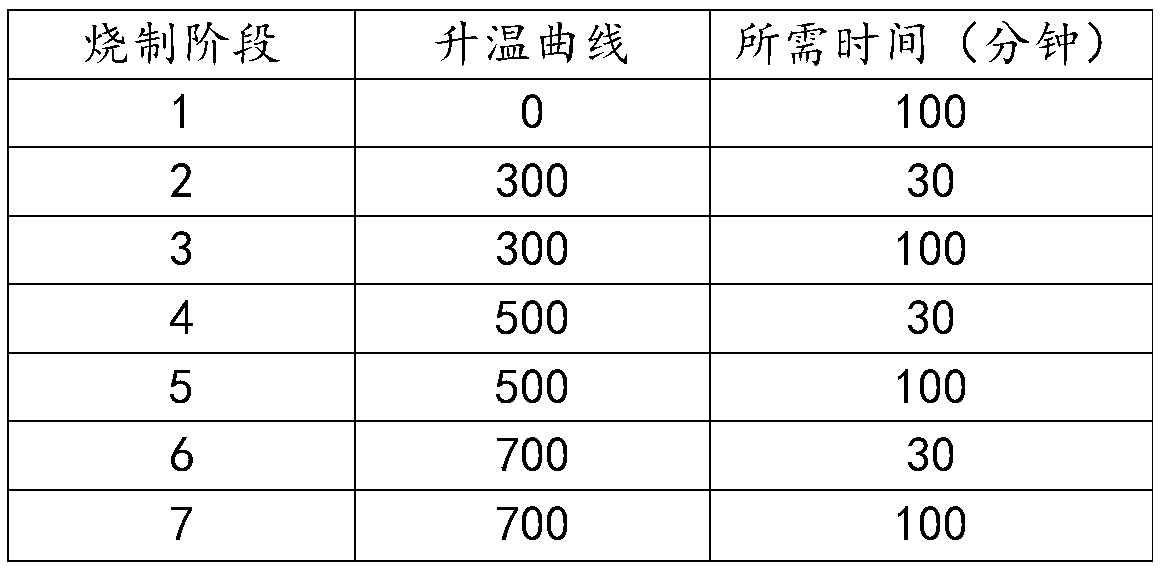

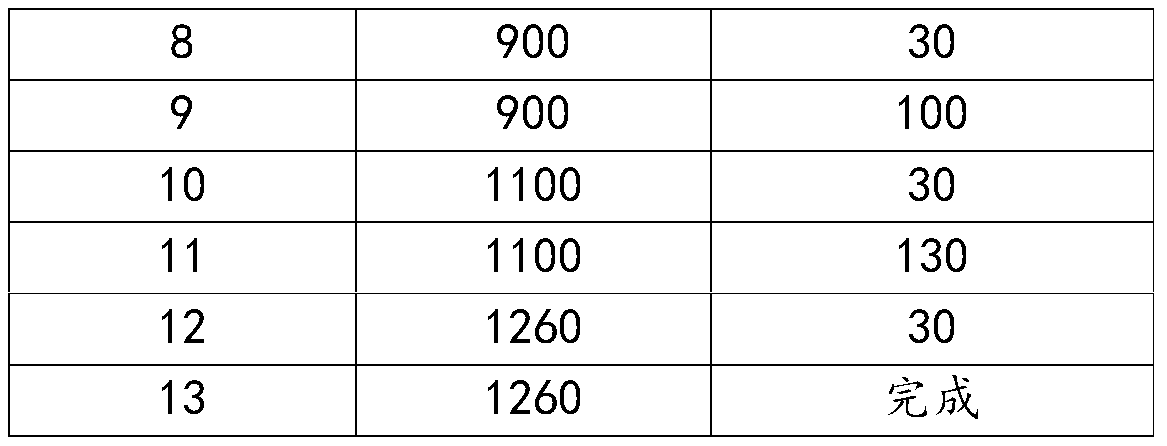

[0035] (3) Put the glaze body prepared in st...

Embodiment 2

[0046] The preparation method of the leaf-based ceramic glaze comprises the following steps:

[0047] (1) In the ball mill, according to the specific gravity of 1:0.7, put the components of the Konoha glaze and water into the ball mill for ball milling, specifically: add the following powders in the weight ratio, 21% SiO 2 , 11%P 2 o 3 , 0.2% Fe 2 o 3 , 12%Al 2 o 3 , 2%Cr 2 o 3 , 0.5% MnO, 8% MgO, 40% CaO, 5.6% K 2 O, and water; the ball in the ball milling tank can not exceed 1 / 2nd of the tank volume, and the ball milling time is about 30 minutes to ensure that the ball milling particles can pass through the 120 mesh screen to obtain the wood leaf glaze;

[0048] (2) Select the cinnabar tire mud material, prepare a mud base with a thickness of 2-3 mm, and spray 1-2 mm of the wood leaf glaze prepared in step (1) after biscuit firing at 850 ° C;

[0049] (3) Put the glaze body prepared in step (2) on the middle and upper layers of the kiln, and use a gas kiln to fire a...

Embodiment 3

[0052] The preparation method of the leaf-based ceramic glaze comprises the following steps:

[0053] (1) In the ball mill, according to the specific gravity of 1:0.7, put the Konoha glaze component and water into the ball mill for ball milling, specifically: add the following powders in the weight ratio respectively, 21% SiO 2 , 11%P 2 o 3 , 0.2% Fe 2 o 3 , 12%Al 2 o 3 , 2%Cr 2 o 3 , 0.5% MnO, 8% MgO, 40% CaO, 5.6% K 2 O, and water; the ball in the ball milling tank can not exceed 1 / 2nd of the tank volume, and the ball milling time is about 30 minutes to ensure that the ball milling particles can pass through the 120 mesh screen to obtain the wood leaf glaze;

[0054] (2) Choose Longquan mud material, prepare a mud base with a thickness of 2-3mm, after low-temperature biscuit firing at 850°C, spray black gold glaze with a thickness of about 2mm, and then spray 1-2mm on the glaze body. Step (1) The prepared wood leaf glaze;

[0055] (3) Put the glaze body prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com