A wood-leaf functional cup based on pore-making technology and preparation method thereof

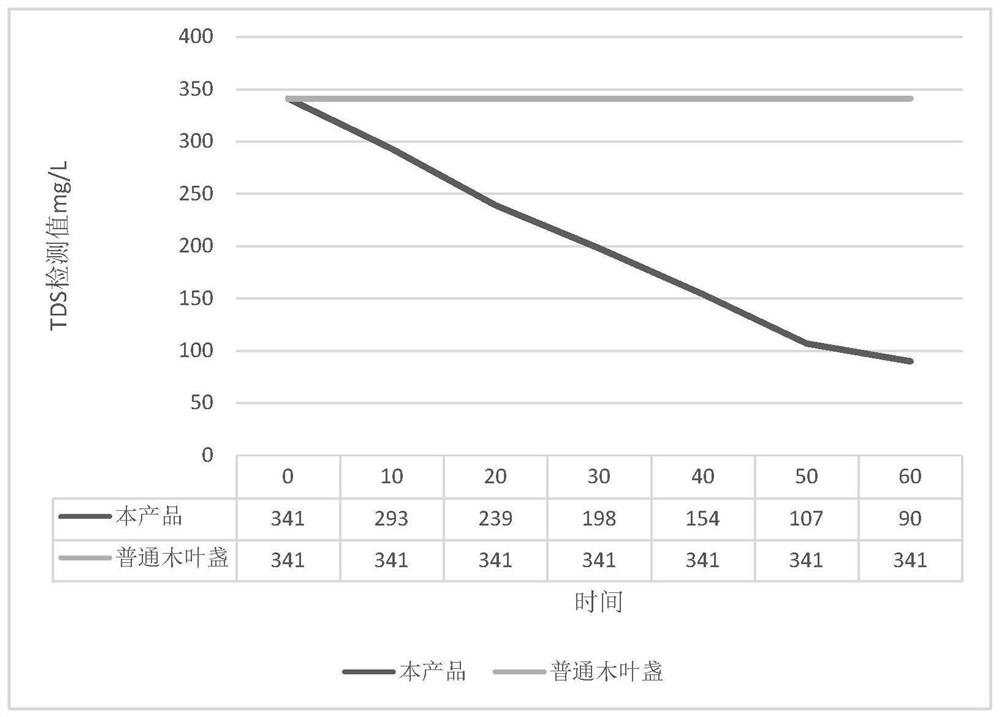

A kind of wood leaf and process technology, applied in the field of wood leaf functional cups and its preparation based on pore-making technology, can solve the problems of limited precipitation of trace elements, affecting the firing efficiency of wood leaf cups, and no precipitation, so as to increase porosity , Stable and reliable firing conditions, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

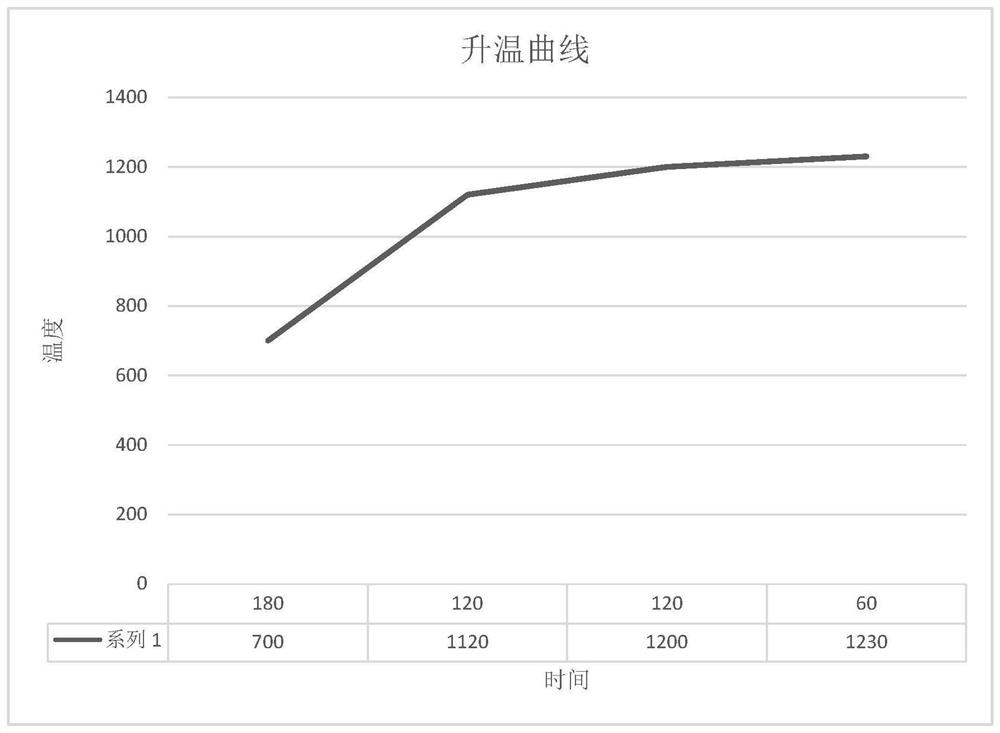

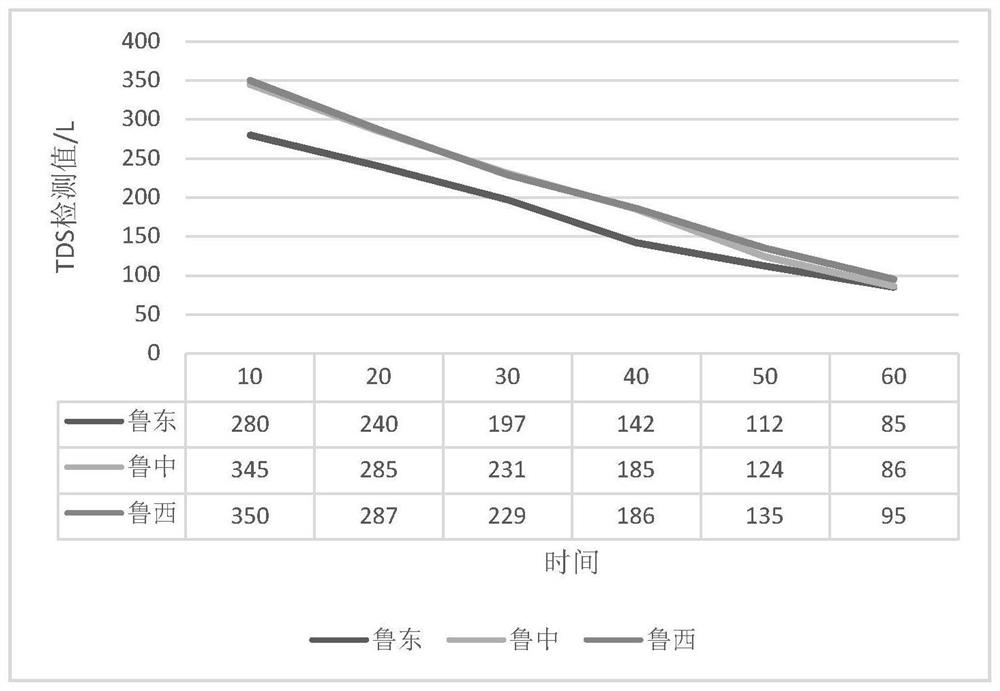

[0029] A method for preparing a wood-leaf functional cup based on a pore-making process, using the following steps:

[0030] (1) In the ball mill, according to the specific gravity of 1:0.7, put the composition of the glaze and water into the ball mill for ball milling, specifically: add the powder in the following weight ratio: K 2 O 6%, Na 2 O 2%, CaO 4%, Al 2 o 3 15%, Fe 2 o 3 4%, SiO 2 62%, P 2 o 5 0.3%, TiO 2 1%, MnO 2 0.1%, and water; the balls in the ball mill tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 60 min, so as to ensure that the ball mill particles can pass through the 120-mesh sieve to obtain the required glaze;

[0031] (2) Clay used: red kaolin 28%, white kaolin 7%, Tuogou pottery clay 27%, feldspar 13%, quartz 4%, CaCO 3 9%, MgO 0.08%, SrO 0.7%, Fe 2 o 3 0.8%, SiO 2 0.6%, TiO 2 0.3%, Na 2 O 0.06%, K 2 O0.01%, prepare the mud base of 2-3mm thickness, after 850 ℃ of low-temperature biscuits, use the ...

Embodiment 2

[0035] A method for preparing a wood-leaf functional cup based on a pore-making process, comprising the following steps:

[0036] (1) In the ball mill, according to the specific gravity of 1:0.7, put the composition of the glaze and water into the ball mill for ball milling, specifically: add the powder in the following weight ratio: K2 O 6%, Na 2 O 2%, CaO 4%, Diatomaceous Earth 6%, Al 2 o 3 15%, Fe 2 o 3 6%, SiO 2 62%, P 2 o 5 0.4%, TiO 2 1%, MnO 2 0.1%, and water; the balls in the ball milling tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 65 min, so as to ensure that the ball milling particles can pass through the 120-mesh sieve to obtain the required glaze;

[0037] (2) Equipped with mud materials 27% red kaolin, 7% white kaolin, 27% Tuogou pottery clay, 12% feldspar, 4% quartz, CaCO 3 9%, MgO 0.08%, SrO 0.7%, Fe 2 o 3 0.8%, SiO 2 0.6%, TiO 2 0.3%, Na 2 O 0.06%, K 2 O0.01%, prepare the mud base of 2-3mm thickness, ...

Embodiment 3

[0041] A method for preparing a wood-leaf functional cup based on a pore-making process, comprising the following steps:

[0042] (1) In the ball mill, according to the specific gravity of 1:0.7, put the composition of the glaze and water into the ball mill for ball milling, specifically: add the powder in the following weight ratio: K 2 O 6%, Na 2 O 2%, CaO 4%, Diatomaceous Earth 3%, Al 2 o 3 15%, Fe 2 o 3 6%, SiO 2 62%, P 2 o 5 0.8%, TiO 2 1%, MnO 2 0.1%, and water; the balls in the ball milling tank should not exceed one-half of the tank volume, and the ball milling time is about 100 min, so that the ball milling particles can pass through the 120-mesh sieve to obtain the required glaze;

[0043] (2) Use clay red kaolin 28% red kaolin, 8% white kaolin, 26% Tuogou pottery clay, 12% feldspar, 4.5% quartz, CaCO 3 1.5%, MgO 0.08%, SrO 0.8%, Fe 2 o 3 0.8%, SiO 2 0.6%, TiO 2 0.3%, Na 2 O0.08%, K 2 O 0.008%, prepare a mud base with a thickness of 2-3mm, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com