Tea dust glaze based on Yellow River mud and preparation method of tea dust glaze

A technology for tea powder and glaze, which is applied in the field of ceramic composite materials, can solve problems such as practical limitations, and achieve the effects of increased yield, simple operation, and stable and reliable firing conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The tea powder glaze based on the Yellow River mud includes glaze raw materials in the following weight ratios:

[0042] Kaolin 12%, incense ash 10%, iron powder 10%, potassium feldspar 39%, quartz 9%, CaCO 3 12%, MgCO 3 8%. The method for making tea powder glaze using the tea powder glaze based on Yellow River mud comprises the following steps:

[0043] (1) In the ball mill, according to the weight ratio of 1:0.7, put the composition of the above-mentioned tea powder glaze and water into the ball mill for ball milling; the balls in the ball mill tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 30 minutes to ensure that the ball mill particles can pass through a 120-mesh sieve to obtain tea powder glaze; set aside;

[0044] (2) Choose the mud from the Yellow River, prepare a mud base with a thickness of 2-3mm, and after biscuit firing at a low temperature of 850°C, spray 1-2mm thick tea powder glaze on the part of the glaze body;

[...

Embodiment 2

[0055] Embodiment 2 (constituent consumption is the same as embodiment 1, and firing temperature changes in the preparation method)

[0056] This tea powder glaze is the same as the tea powder glaze of embodiment 1, and the preparation method comprises the following steps:

[0057] (1) In the ball mill, according to the weight ratio of 1:0.7, put the composition of the above-mentioned tea powder glaze and water into the ball mill for ball milling; the balls in the ball mill tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 30 minutes to ensure that the ball mill particles can pass through a 120-mesh sieve to obtain tea powder glaze; set aside;

[0058] (2) Choose purple sand mud, prepare a mud base with a thickness of 2-3mm, and after biscuit firing at a low temperature of 850°C, spray 1-2mm thick tea powder glaze on the part of the glaze body;

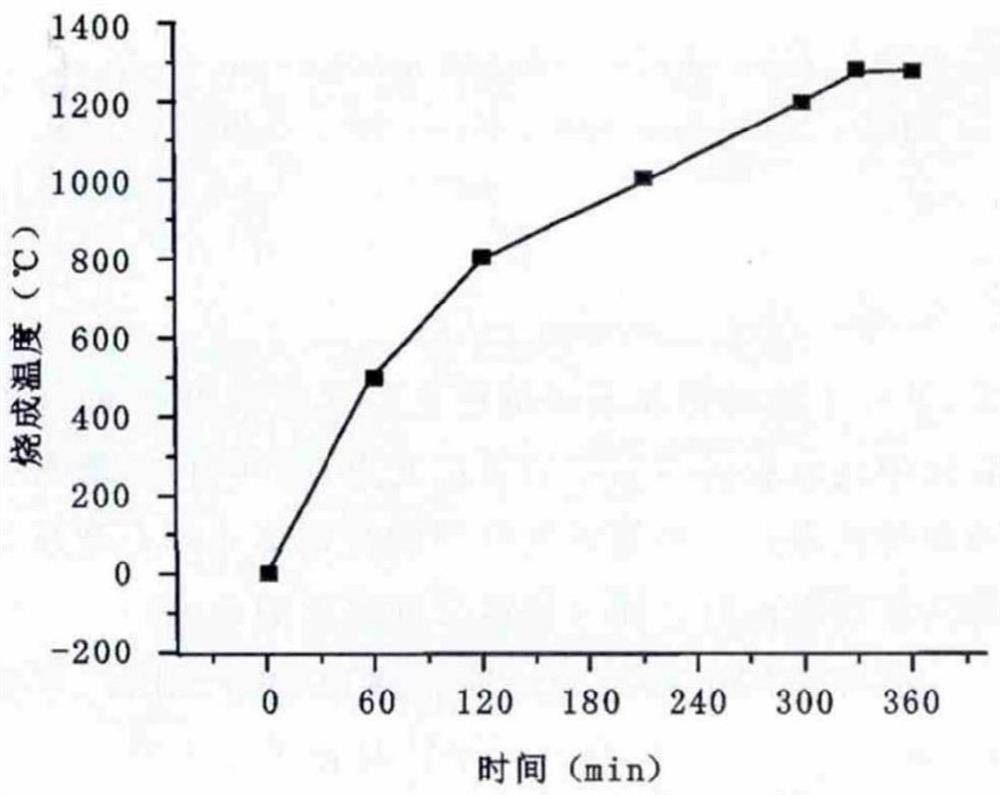

[0059] (3) Put the glaze body prepared in step (2) on the middle and upper layers of the kiln, and ...

Embodiment 3

[0062] The tea powder glaze comprises glaze raw materials in the following weight ratios:

[0063] Kaolin 11%, incense ash 9%, iron powder 10%, potassium feldspar 38%, quartz 9%, CaCO 3 15%, MgCO 3 8%.

[0064] The method and firing method of using the tea powder glaze to make the tea powder glaze are the same as the preparation method and firing method of Example 1, the difference is that the mud is Longquan mud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com