Blue base glaze for Konoha cup and method for making Konoha cup using the blue bottom glaze for Konoha cup

A technology of wood leaf cup and bottom glaze, applied in the field of ceramic materials, can solve the problems of not carefully examining whether there is heavy metal in porcelain, unclear leaf vein texture of wood leaf cup, unable to meet food-grade standards, etc., and achieve stable firing conditions. Reliable, enhance aesthetic value and aesthetic space, colorful and glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The blue base glaze of the Konoha cup and the method for making the Konoha cup provided in this example adopt the raw materials and proportioning of Example 1 in Table 1, and the specific production steps are as follows:

[0037] (1) Obtaining the green body: select high white porcelain clay with low iron content, and adopt the conventional body forming and trimming methods of daily-use ceramics to prepare a green body with a thickness of 2-3mm, and store the green body in Dry naturally in a cool place to make the water content of the green body reach 1-2%;

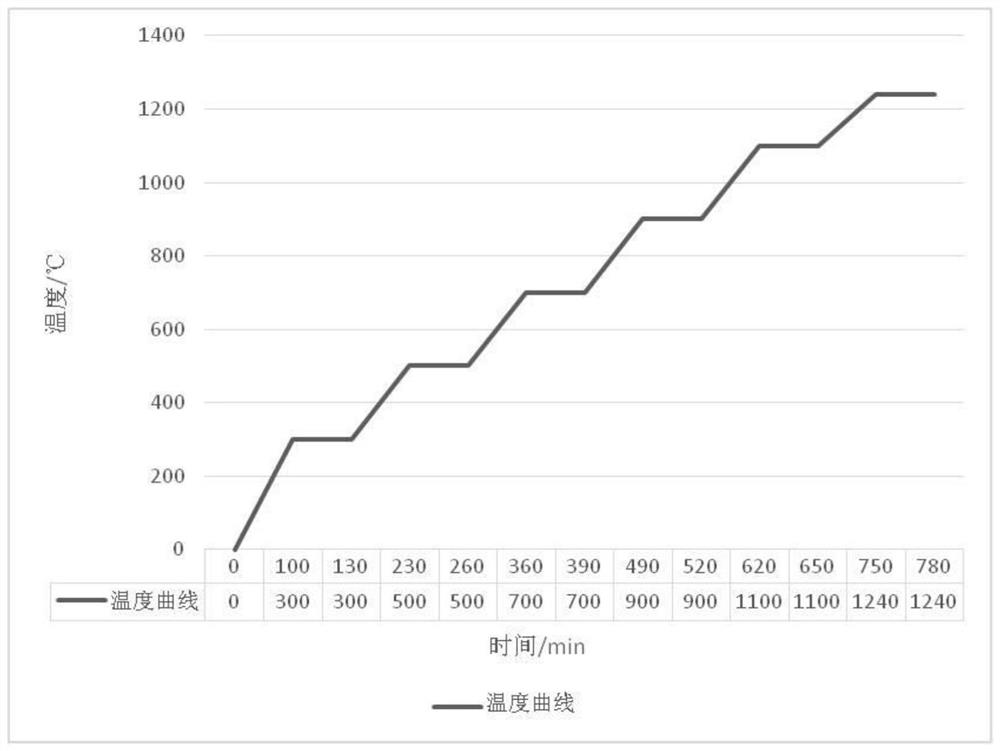

[0038] (2) Low-temperature biscuit firing: use a kiln for daily-use ceramic production to carry out low-temperature biscuit firing on the naturally dried green body. The temperature of low-temperature biscuit firing is 850°C to prepare a biscuit green body; the specific firing of low-temperature bisque firing The preparation method is: heat from room temperature to 850°C at a heating rate of 2-3°C / min, and keep war...

Embodiment 2

[0055] The blue bottom glaze of the Konoha cup and the method for making the Konoha cup provided in this example adopt the raw materials and proportions of Example 2 in Table 1, and the specific production steps are as follows:

[0056] (1) Obtain the green body: choose high white porcelain clay with low iron content, adopt the conventional green body molding and trimming methods of daily-use ceramics, prepare a 2-3mm thick green body, and store the green body in a cool place Dry naturally, so that the water content of the green body reaches 1-2%;

[0057] (2) Low-temperature biscuit firing: use a kiln for daily-use ceramic production to carry out low-temperature biscuit firing on the naturally dried green body. The temperature of low-temperature biscuit firing is 850°C to prepare a biscuit green body; the specific firing of low-temperature bisque firing The preparation method is: heat from room temperature to 850°C at a heating rate of 2-3°C / min, and keep warm for 30 minutes;...

Embodiment 3

[0066] The blue bottom glaze of the Konoha cup and the method for making the Konoha cup provided in this embodiment adopt the raw materials and proportioning of Example 3 in Table 1, and the specific manufacturing method differs from Example 2 in that:

[0067] In step (6), when firing at high temperature, start from room temperature, at a heating rate of 3°C / min, keep warm for 30min every 200°C, heat up to 1230°C, keep warm for 30min, and then cool naturally to room temperature.

[0068] When glazing in step (4) of the above-mentioned examples 1-3, it is not limited to the method of spraying glaze, but the method of dipping glaze can also be used, but the glaze slurry needs to be diluted, if it is too thick, the glaze will shrink easily, and the green body is dipped in glaze. Afterwards, the glaze layer needs to be dehydrated by drying or drying.

[0069] The traditional black-glazed wooden leaf cup is not affected, but the application of the present invention uses blue glaze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com