Method for preparing titanium carbonitride from titanium carbonitride powder and hydrolyzable titanium source

A titanium carbonitride, hydrolyzable technology, applied in the field of ceramic powder preparation, can solve the problems of material defects, easy denitrification, difficult to achieve mass production, etc., and achieve the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Titanium carbonitride was prepared according to the following steps:

[0044] (1) Mix 300ml of cyclohexane with 150ml of ethanol, adjust the pH to 2~3, add 12g of cetyltrimethylammonium bromide, adjust the pH to 2~3, and slowly drop in the 24ml of titanium tetrachloride to obtain liquid A. Mix 150ml ethanol with 50ml deionized water. Add 18g of cetyltrimethylammonium bromide and 6.68g of carbon black, and stir for 30 minutes to obtain liquid B. Mix liquids A and B and continue to stir for 30 minutes.

[0045] (2) Mix 150ml of ammonia water and 150ml of deionized water, pour it into an infusion bottle, use a 34G needle under high-speed magnetic stirring conditions, drop the diluted ammonia water into the mixed solution obtained in (1), and wait until the pH is 7 Stop dripping ammonia. The suspension was suction filtered to extract the precipitate.

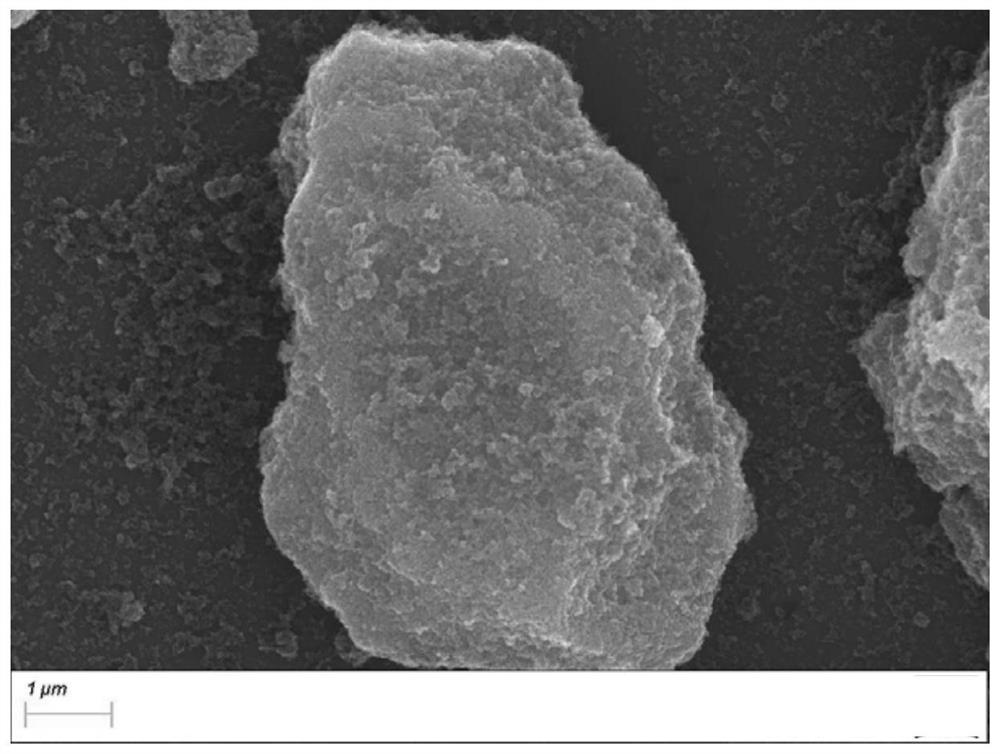

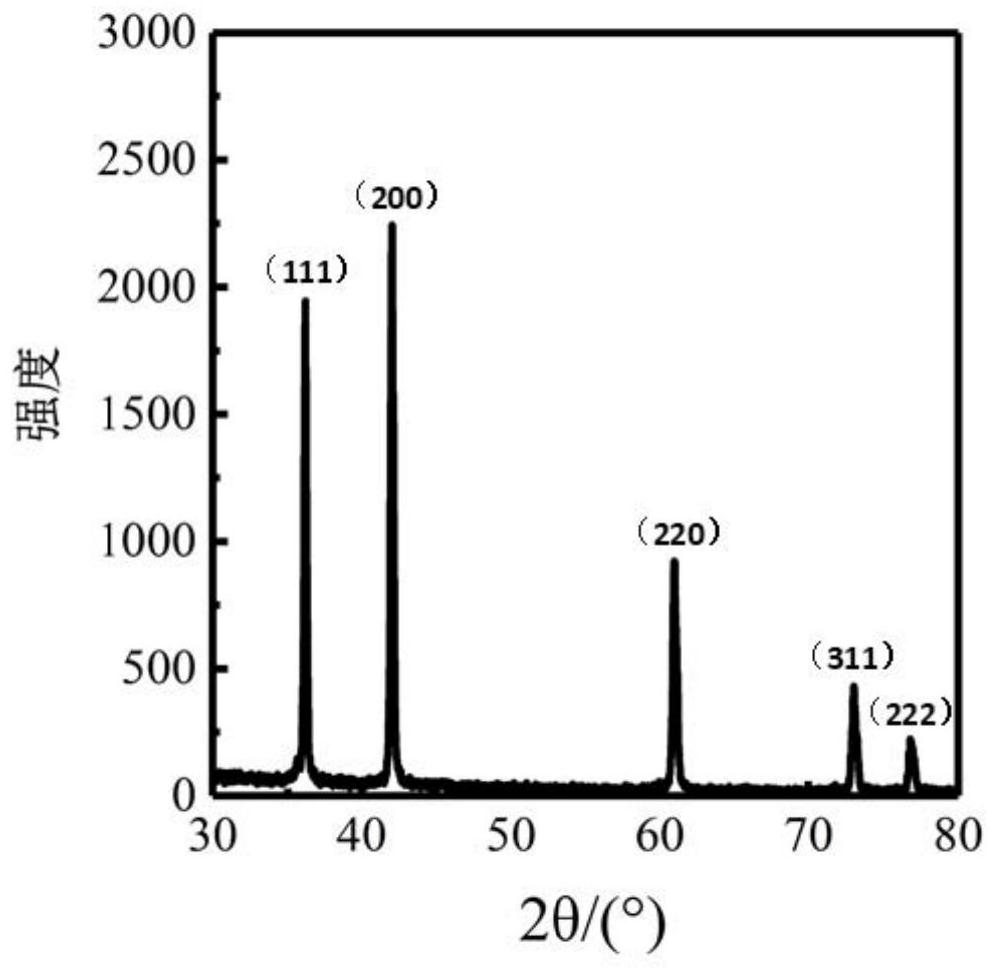

[0046] (3) After the precipitate is dried, it is heated to 600° C. in a vacuum tube furnace and kept for 2 hours to ob...

Embodiment 2

[0051] Titanium carbonitride was prepared according to the following steps:

[0052] (1) Mix 600ml of cyclohexane with 300ml of ethanol, adjust the pH to 2~3, add 20g of cetyltrimethylammonium bromide, adjust the pH to 2~3, and slowly drop in the 48ml of titanium tetrachloride was obtained as liquid A. Mix 300ml ethanol with 200ml deionized water. Add 25g of cetyltrimethylammonium bromide and 12.33g of carbon black, and stir for 30min to obtain liquid B. Mix liquids A and B and continue to stir for 30 minutes.

[0053] (2) Mix 250ml of ammonia water and 250ml of deionized water, pour it into an infusion bottle, and use a 34G needle under high-speed magnetic stirring conditions, drop the diluted ammonia water into the mixed solution obtained in (1) until the pH is 7 Stop dripping ammonia. The suspension was suction filtered to extract the precipitate.

[0054] (3) After the precipitate is dried, it is heated to 600° C. in a vacuum tube furnace and kept for 2 hours.

[005...

Embodiment 3

[0058] Titanium carbonitride was prepared according to the following steps:

[0059] (1) Mix 300ml of cyclohexane with 150ml of ethanol, adjust the pH to 2~3, add 12g of cetyltrimethylammonium bromide, adjust the pH to 2~3, and slowly drop in the 24ml of titanium tetrachloride to obtain liquid A. Mix 150ml ethanol with 50ml deionized water. Add 18g of cetyltrimethylammonium bromide and 6.68g of carbon black to obtain liquid B. Mix liquids A and B and continue to stir for 30 minutes.

[0060] (2) Mix 150ml of ammonia water and 150ml of deionized water, pour it into an infusion bottle, use a 34G needle under high-speed magnetic stirring conditions, drop the diluted ammonia water into the mixed solution obtained in (1), and wait until the pH is 7 Stop dripping ammonia. The suspension was suction filtered to extract the precipitate.

[0061] (3) After the precipitate is dried, it is heated to 600° C. in a vacuum tube furnace and kept for 2 hours.

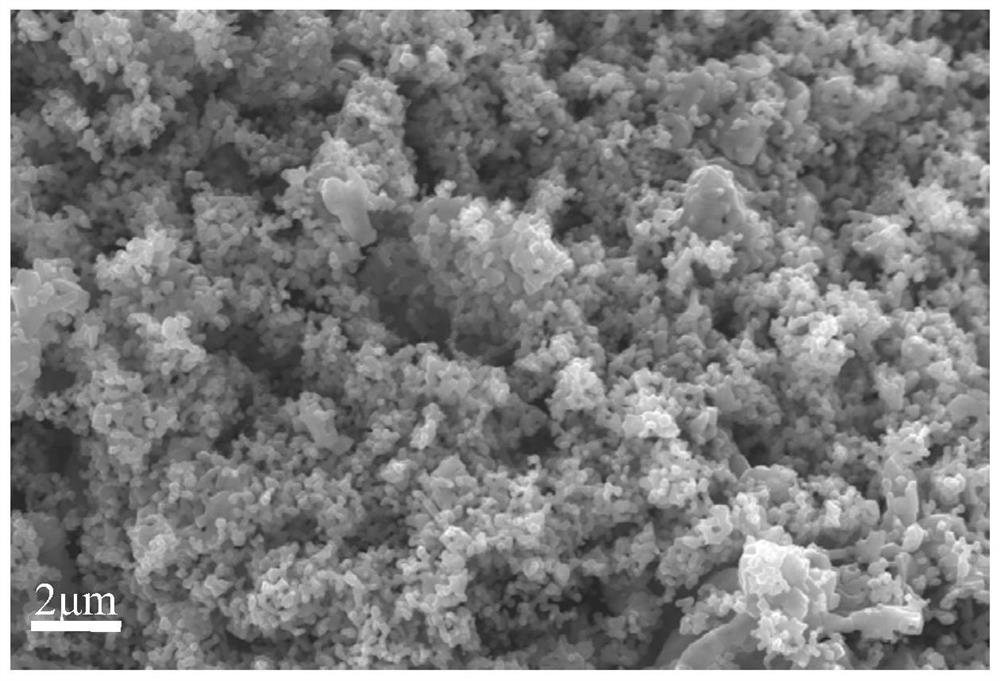

[0062] (4) Grind the precu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com