Ion beam metallization method of LCP base material and product thereof

A metallization and ion beam technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem that the plasma deposition layer is difficult to obtain bonding force, impossible to meet the requirements, and lacks high bonding force LCP metal Problems such as chemicalization methods, to achieve the effect of improving compactness and peel strength, strong peel strength, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) The surface of the LCP substrate is activated. The surface of the LCP substrate is treated by a Kaufman ion source to form a surface activation layer. The voltage is 15kV, the activation gas is Ar, the current is 600mA, and the activation time is 45s;

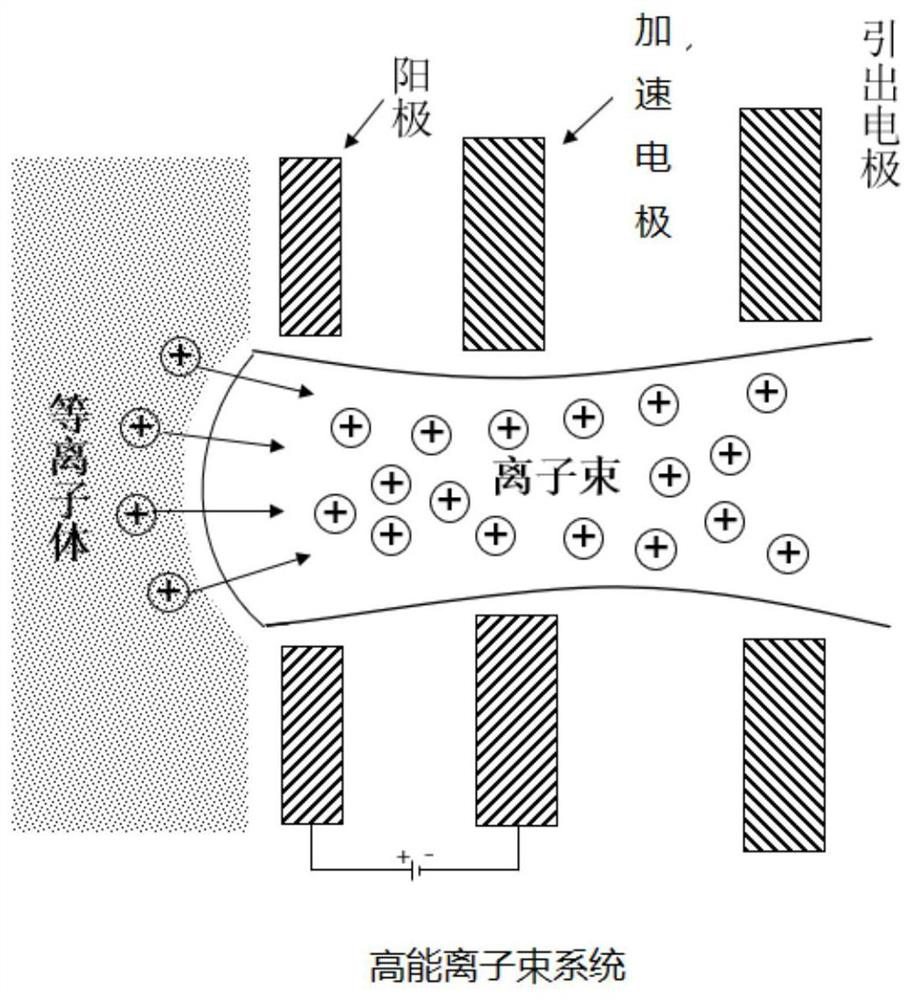

[0045] (2) Form a mixed layer, mix high-energy metal ions in the cross-linked layer through a high-energy ion source system to form a metal-nonmetal mixed layer, the mixed metal is Ni, the ion beam energy is 8keV, and the treatment dose is 1*10 15 ions / cm 2 ;

[0046] (3) Ion beam deposition, metal ions are deposited in the transition layer through a low-energy ion source system, the deposited metal is Cu, the deposition voltage is 30V, and the deposition current is 100A. When the low-energy ion beam and the high-energy ion beam are working, the vacuum degree is maintained at 2 MilliPascal, the working voltage of the electron gun is 1000V, and the magnetic field is 100mT.

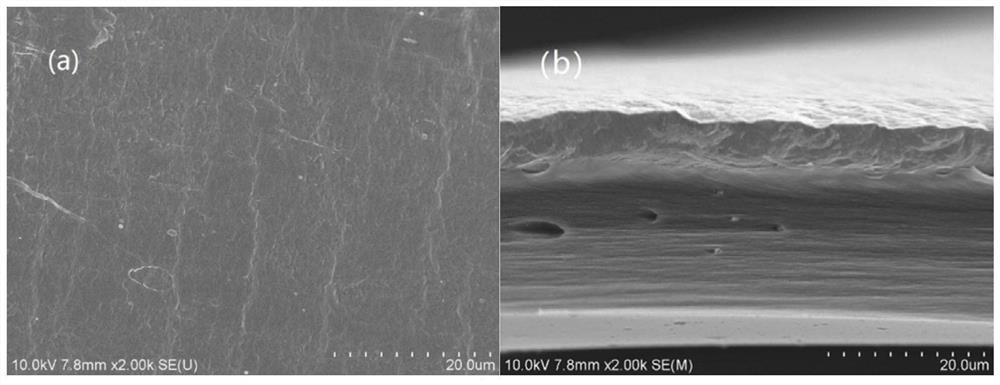

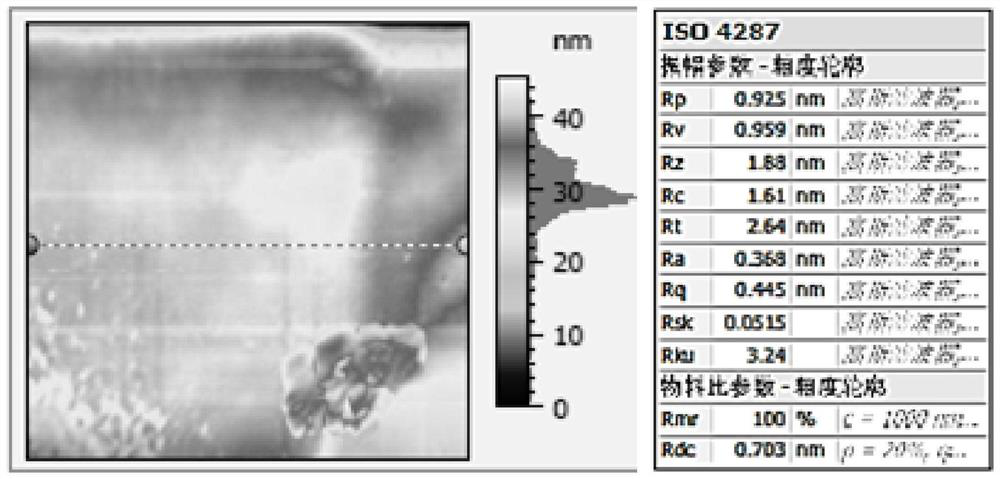

[0047] The LCP copper-clad laminate was t...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 lies in that the processing energy of the Kaufmann ion source in step (1) is different.

[0050] (1) The surface of the LCP substrate is activated. The surface of the LCP substrate is treated by a Kaufmann ion source to form a surface activation layer. The voltage is 10kV, the activation gas is Ar, the current is 600mA, and the activation time is 45s;

[0051] (2) Form a mixed layer, mix high-energy metal ions in the cross-linked layer through a high-energy ion source system to form a metal-nonmetal mixed layer, the mixed metal is Ni, the ion beam energy is 8keV, and the treatment dose is 1*10 15 ions / cm 2 ;

[0052] (3) Ion beam deposition, metal ions are deposited in the transition layer through a low-energy ion source system, the deposited metal is Cu, the deposition voltage is 30V, and the deposition current is 100A. When the low-energy ion beam and the high-energy ion beam are working, the vacuum degree is ma...

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 lies in that the processing energy of the Kaufmann ion source in step (1) is different.

[0056] (1) The surface of the LCP substrate is activated. The surface of the LCP substrate is treated by a Kaufman ion source to form a surface activation layer. The voltage is 5kV, the activation gas is Ar, the current is 600mA, and the activation time is 45s;

[0057] (2) Form a mixed layer, mix high-energy metal ions in the cross-linked layer through a high-energy ion source system to form a metal-nonmetal mixed layer, the mixed metal is Ni, the ion beam energy is 8keV, and the treatment dose is 1*10 15 ions / cm 2 ;

[0058] (3) Ion beam deposition, metal ions are deposited in the transition layer through a low-energy ion source system, the deposited metal is Cu, the deposition voltage is 30V, and the deposition current is 100A. When the low-energy ion beam and the high-energy ion beam are working, the vacuum degree is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com