Method for measuring radius of curvature of lens based on interference of composite vortex light

A compound vortex and radius of curvature technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of decreased measurement accuracy and difficult calibration, and achieve the goal of improving measurement accuracy, improving measurement accuracy, and increasing the number of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

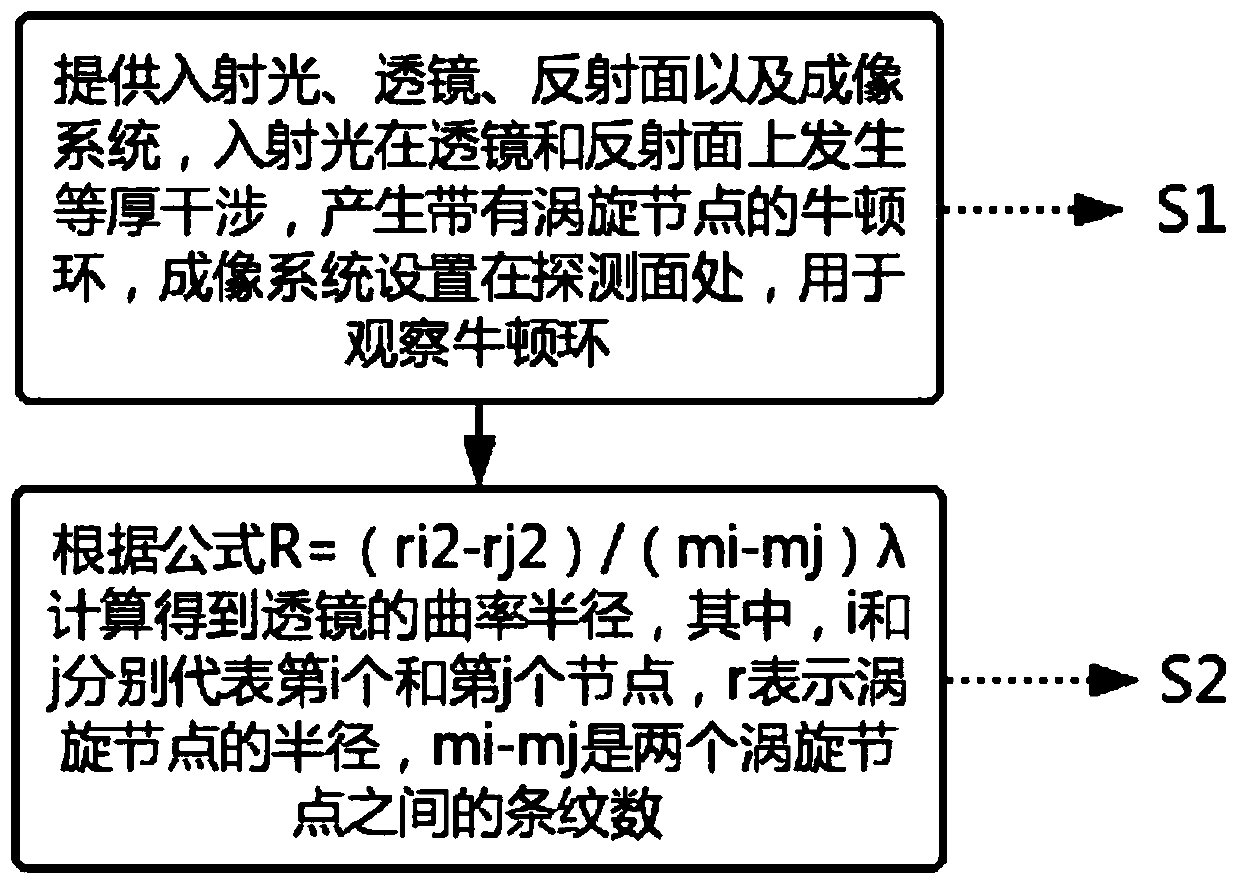

[0031] See figure 1 , a method for measuring the radius of curvature of a lens based on compound vortex light interference of the present invention, comprising the following steps:

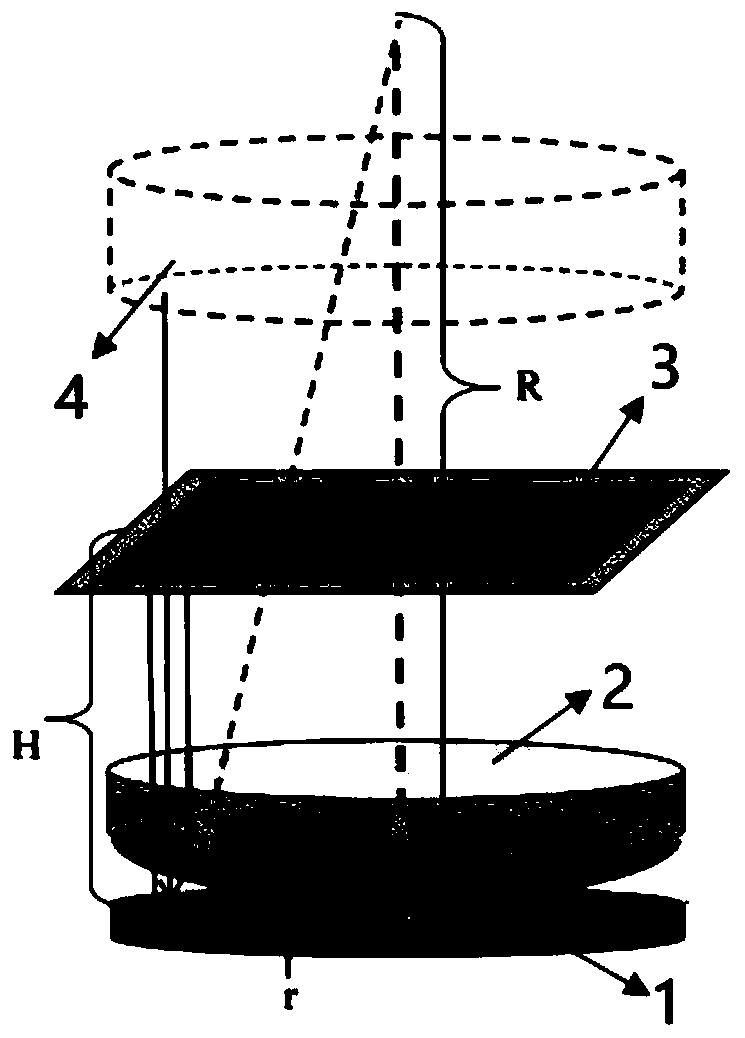

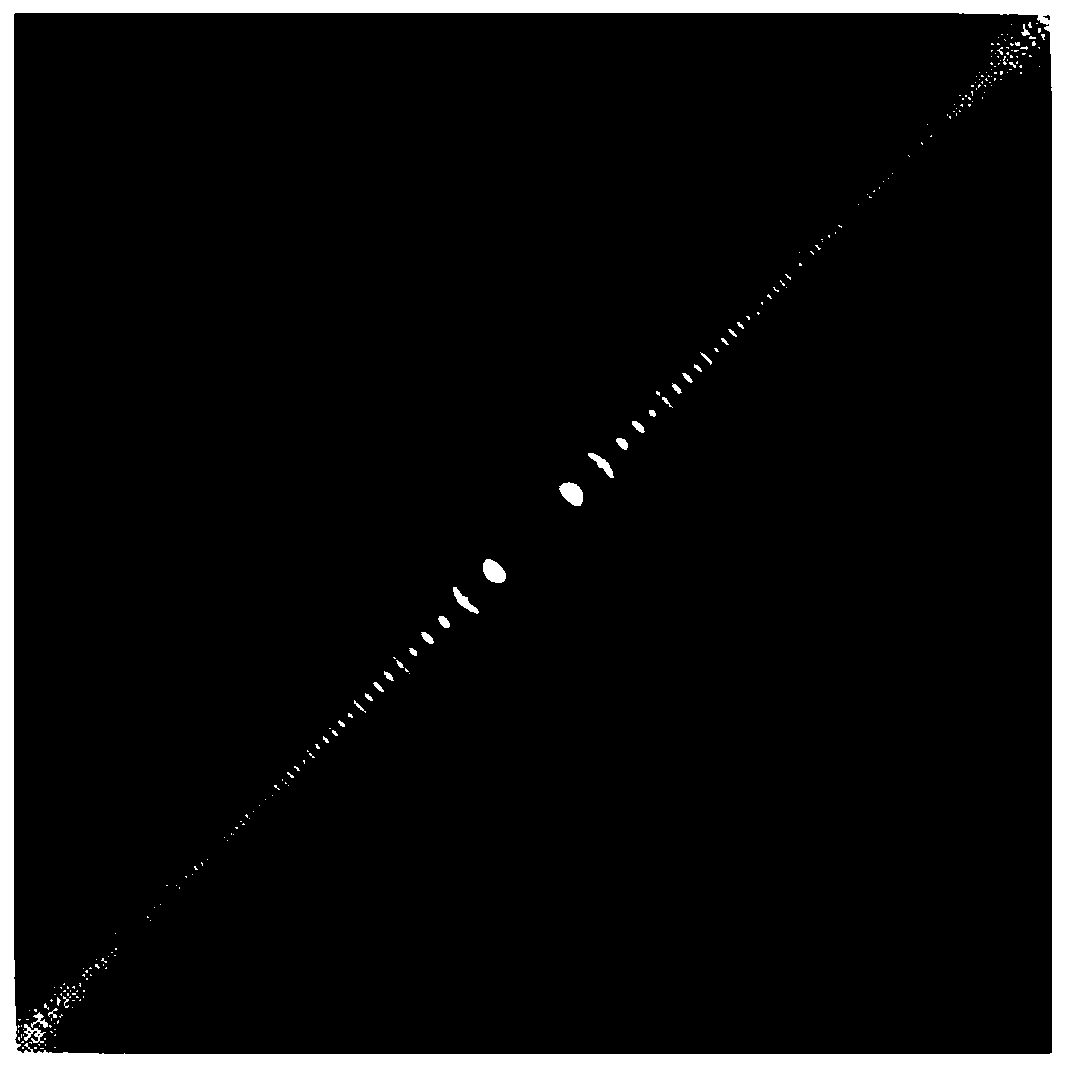

[0032] S1. Provide incident light, lens, reflective surface and imaging system. The reflective surface is one side of the flat glass. When the incident light is irradiated on the reflective surface, no diffuse reflection occurs. The incident light is on the said reflective surface. Equal-thickness interference occurs on the lens and the reflective surface to produce a Newton ring with vortex nodes, and the imaging system is arranged at the detection surface to observe the Newton ring (when th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap