A flexible fixture with integrated assembly force detection

A flexible fixture and assembly force technology, applied in the field of processing and manufacturing, can solve the problems of inability to measure and control the clamping force, large size span, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The flexible fixture for integrated assembly force detection in the present invention includes two fixtures and matching tooling.

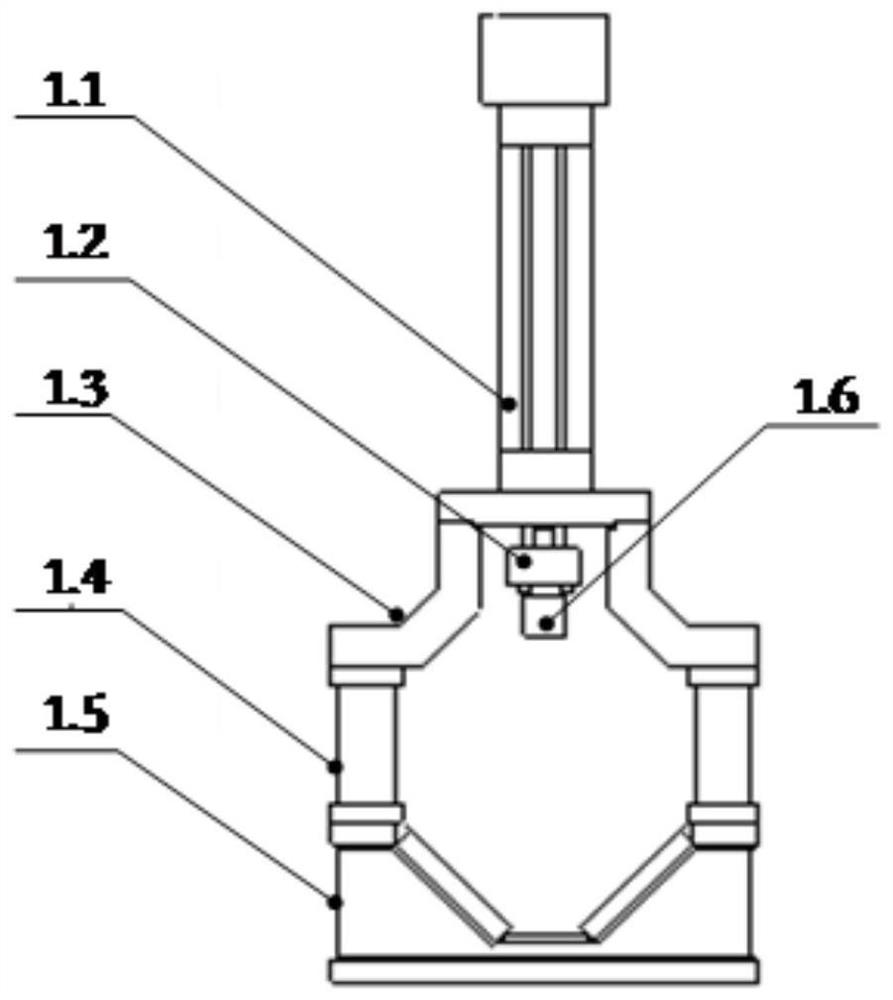

[0030] Fixture 1 is composed of fixture A base 1.5, support column 1.4, upper cover 1.3, three-dimensional force sensor 1.2, electric cylinder 1.1, etc.; the support column is respectively connected to the base 1.5 and upper cover 1.3 by screws, and the electric cylinder 1.1 is connected to the upper cover 1.3 by screws One end of the three-dimensional sensor 1.2 is installed on the end of the electric cylinder push rod through threads, and the other end is installed with a polytetrafluoroethylene contact block 1.6 to avoid damage to the surface of the workpiece when clamping the workpiece; when the workpiece is clamped, the electric cylinder is driven to pass through the electric cylinder push rod To clamp the workpiece, the clamping force can be controlled by controlling the current.

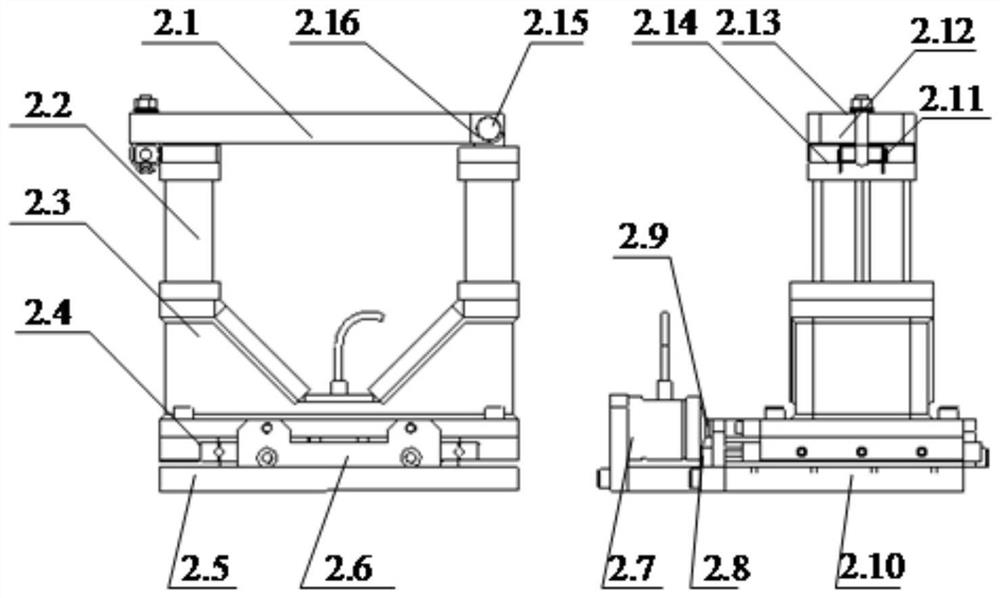

[0031]Fixture 2 is composed of upper platen 2.1, supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com