Low-noise food processor

A food processing machine, low-noise technology, applied in the field of food processing, can solve the problems of large noise on the countertop, direct downward airflow, easy impact of airflow, etc., to achieve the effect of avoiding noise, avoiding backflow and counterflow of airflow, and accelerating airflow circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

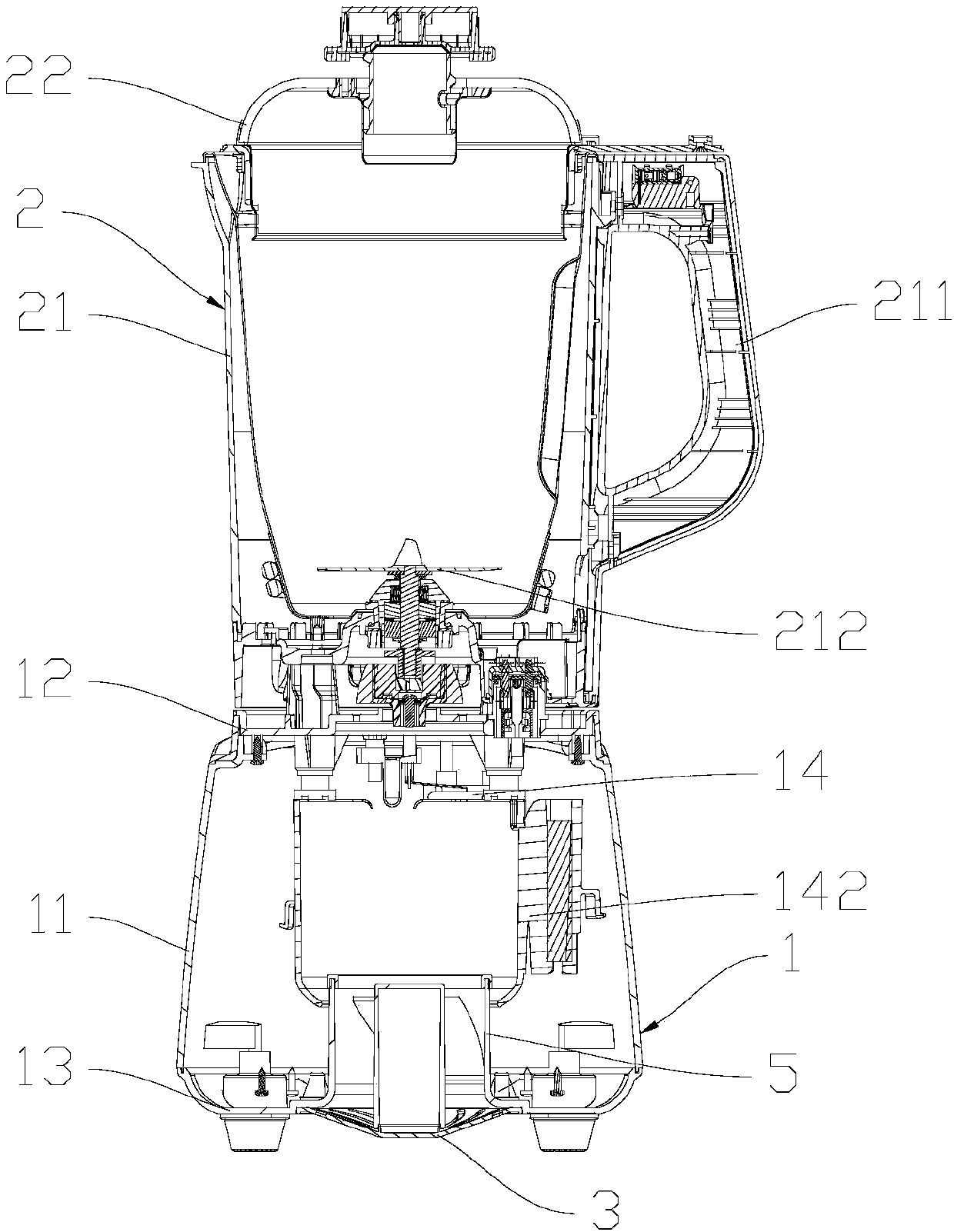

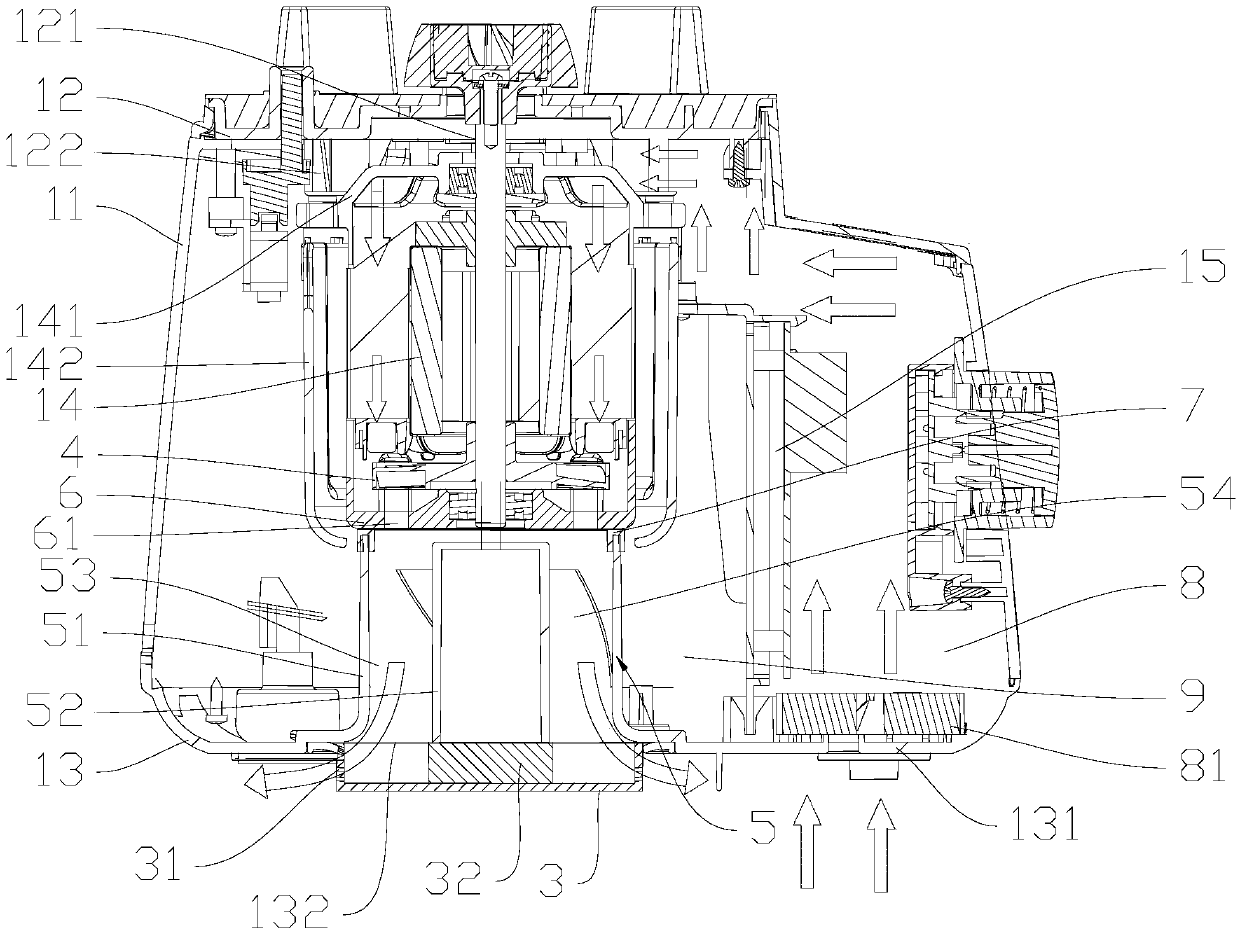

[0035] like figure 1 and figure 2As shown, the food processor of this embodiment includes a machine base 1 and a stirring cup 2 connected to the machine base 1. The machine base 1 includes a casing 11, a top cover 12 and a bottom cover 13, and the top cover 12 and the bottom cover 13 are respectively Located on the top and bottom of the casing 11, the base 1 is provided with a motor 14 and a circuit board 15, the motor 14 and the circuit board 15 are located in the casing 11, the stirring cup 2 includes a cup body 21 and a cup cover 22, the cup body 21 It is a glass cup with a handle 211, and the cup cover 22 is a plastic cup cover. The cup cover 22 and the cup body 21 are enclosed to form a crushing space. The cup body 21 is provided with a crushing knife 212. connection, the two are connected by a coupling, the coupling includes an upper coupling and a lower coupling, the upper coupling is connected with the cutter shaft of the crushing knife 212, and the lower coupling is...

Embodiment 2

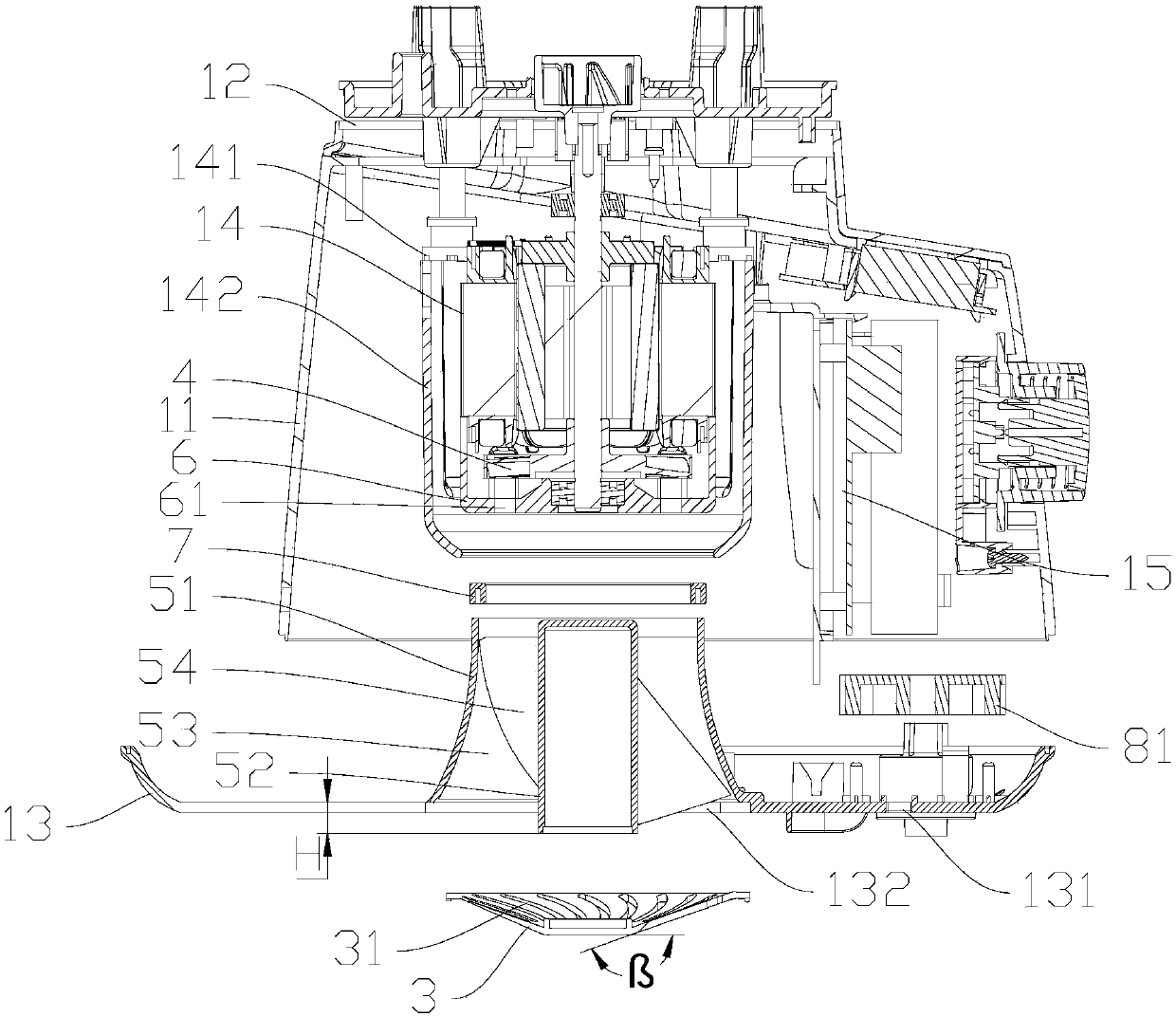

[0043] The difference between this embodiment and Embodiment 1 lies in the structure of the air duct and the exhaust hood, combined with Figure 3 to Figure 5 As shown, the connection between the first annular wall 51 of the air guide tube 5 and the bottom cover 13 has a radian α, that is, the connection between the lower end of the first annular wall 51 and the bottom cover 13 has a radian α, wherein 5°≤α≤ 35°. In this embodiment, α is 15°, which can guide the airflow out of the air guide tube 5 to the side, thereby avoiding the noise and airflow backflow caused by most of the airflow directly hitting the table surface directly, so that the ventilation of the machine base 1 is very good. smooth. The lower end of the first annular wall 51 extends outward to form a cylinder seat 511, which is located above the air outlet 132 and fixed on the bottom cover 13 by screws, and the first annular wall 51 is installed on the bottom cover 13 through the cylinder seat 511 Above all, thi...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the installation structure of the motor, combined with Figure 6 and Figure 7 As shown, the upper end of the motor 14 is provided with a motor bracket 141, and the motor 14 is fixedly arranged under the top cover 12 through the motor bracket 141. There is a distance A between the motor bracket 141 and the top cover 12, wherein 10mm≤A≤30mm, the distance A Form a communication channel connecting the top of the air inlet chamber 8 with the top of the exhaust chamber 9. In this embodiment, A is 18mm, which can effectively ensure that the airflow flowing through the air inlet chamber 8 passes through the motor from top to bottom to dissipate heat from the motor , the bottom cover 13 is provided with a bracket, the bracket is located below the motor 14 and abuts against the lower end of the motor 14. In this way, the upper and lower ends of the motor 14 are set to support and limit, which can ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com