Chip lifting device and method of use thereof

A chip and spacer technology, applied in the field of chip pulling device, can solve the problems of manual pulling, effort, chip damage, etc., and achieve the effect of easy operation, simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

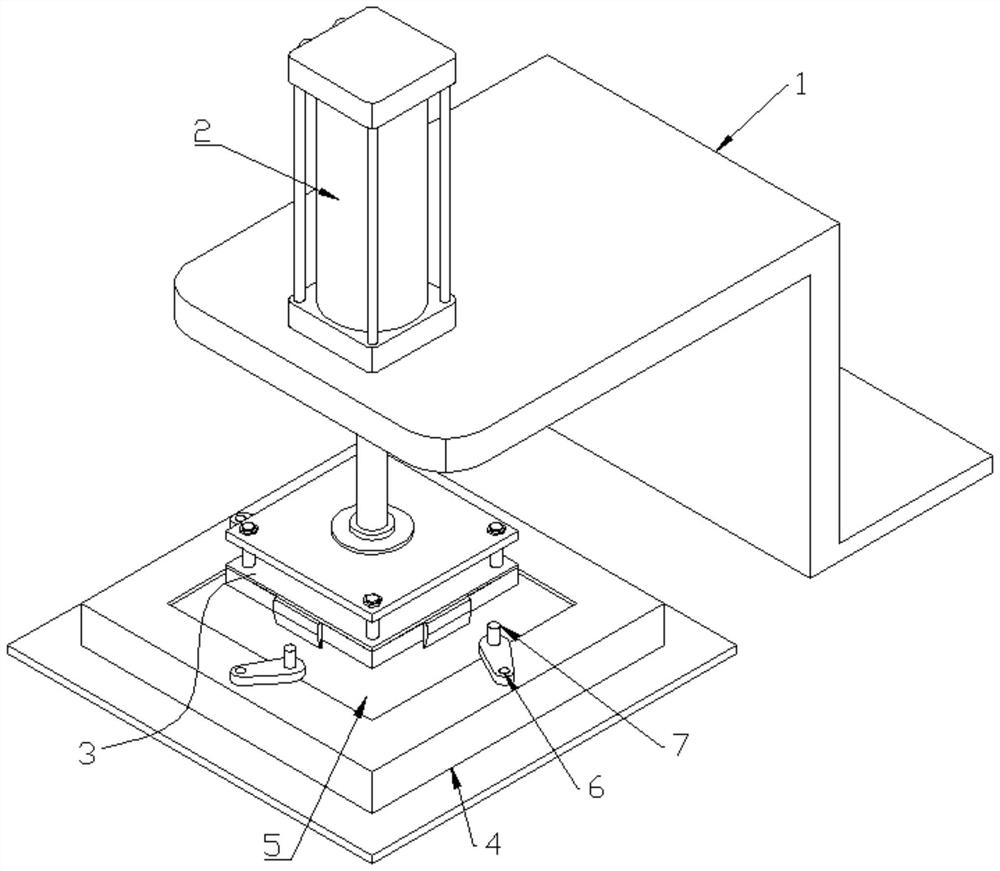

[0033] Such as Figure 1 to Figure 6 As shown, a chip lifting device includes a support 1, an actuator 2, a grabbing mechanism 3 and a chip placement table 4;

[0034] The actuator 2 is installed on the support 1, and the support 1 is provided with reinforcing ribs 13, and the lower end of the actuator 2 is connected to the grasping mechanism 3 and drives the grasping mechanism 3 to move up and down;

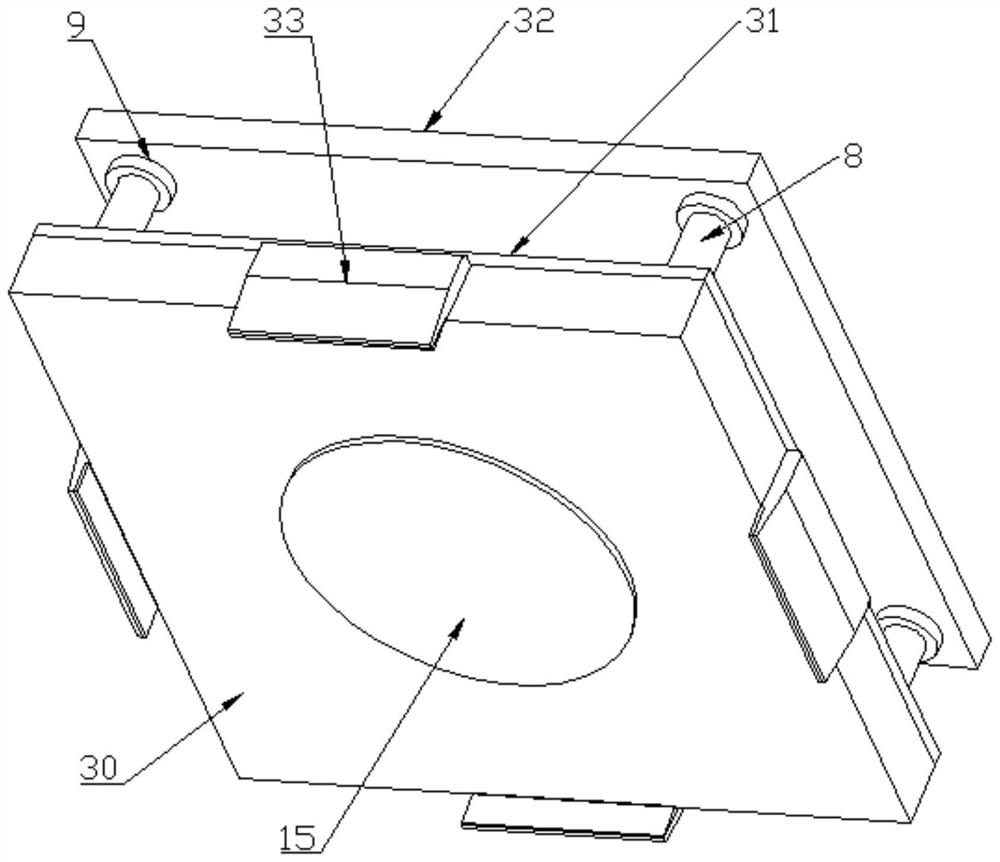

[0035] The grasping mechanism 3 is used to grasp the chip and pull out the chip by means of the actuator 2, which specifically includes a base 30, a cover plate 31, a connecting plate 32, claws 33, a connecting rod 34, a turntable 35, Worm wheel 36, worm screw 37 and rotary drive motor 38, described base 30 is provided with four guide grooves 39 and the angle between two adjacent guide grooves 39 is 90 degrees, guide block 310 is slidably connected in guide groove 39 , the outer end of the guide block 310 is connected to the claw 33, the inner end of the guide block 310 is hing...

Embodiment 2

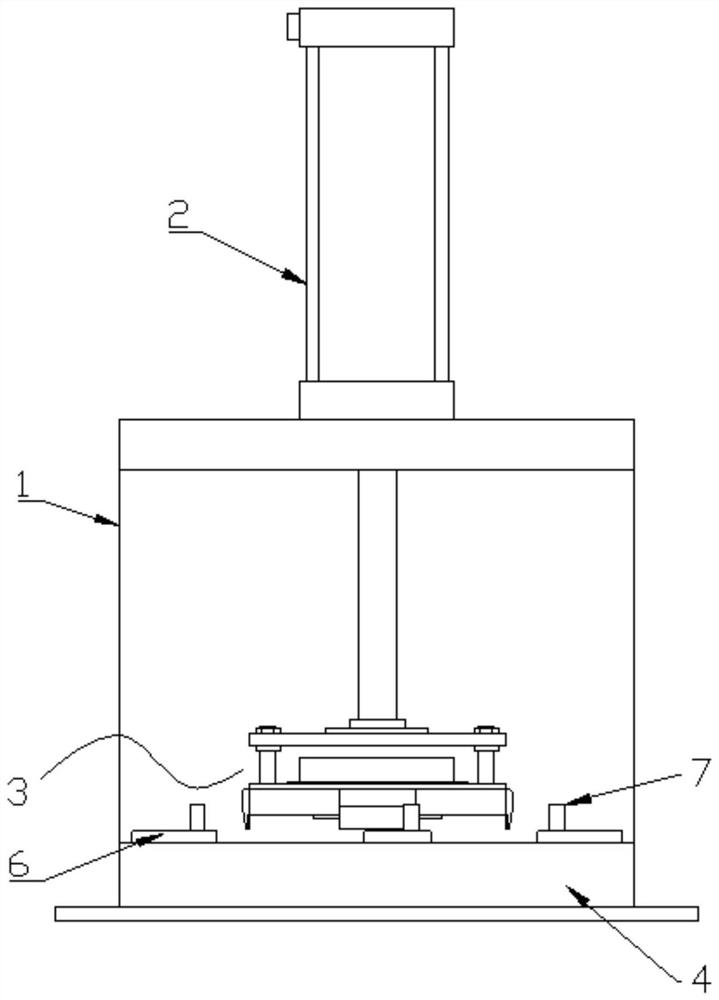

[0041] Such as Figure 7 to Figure 9 As shown, a chip lifting device includes a support 1, an actuator 2, a grabbing mechanism 3 and a chip placement table 4;

[0042] The actuator 2 is installed on the support 1, and the support 1 is provided with reinforcing ribs 13, and the lower end of the actuator 2 is connected to the grasping mechanism 3 and drives the grasping mechanism 3 to move up and down;

[0043] The grasping mechanism 3 is used to grasp the chip and pull out the chip by means of the actuator 2, which specifically includes a base 30, a cover plate 31, a connecting plate 32, claws 33, a connecting rod 34, a turntable 35, Worm wheel 36, worm screw 37 and rotary drive motor 38, described base 30 is provided with four guide grooves 39 and the angle between two adjacent guide grooves 39 is 90 degrees, guide block 310 is slidably connected in guide groove 39 , the outer end of the guide block 310 is connected to the claw 33, the inner end of the guide block 310 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com