Semicircular tool cutting assembly for aluminum foil paper

A semi-circular knife and aluminum foil paper technology, which is applied in metal processing and other directions, can solve the problems such as large fluctuations in the gap between the semi-circular knife blade and the backing knife, lack of hardness and stiffness of composite aluminum foil paper, and inability to ensure accurate positioning of the semi-circular knife. It achieves the effect of easy maintenance, solving unstable cutting and improving equipment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

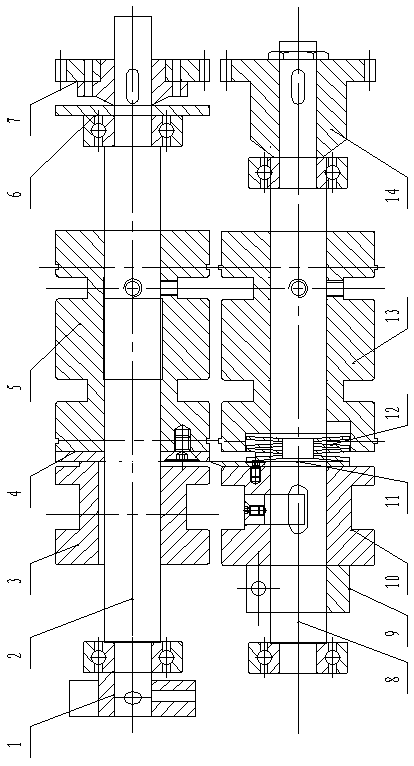

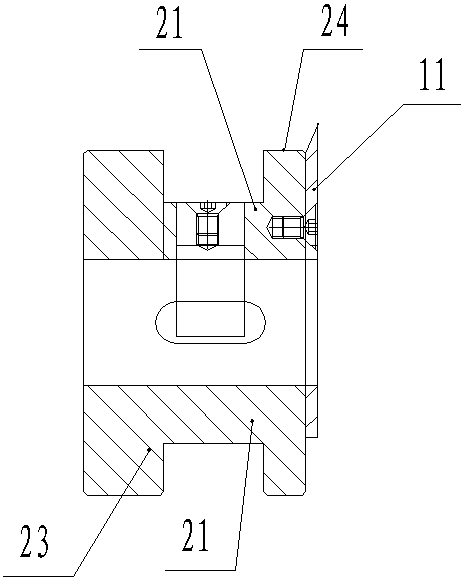

[0039] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] like figure 1 and figure 2 As shown, this embodiment discloses an aluminum foil semi-circular knife cutting assembly, which includes two roller shafts arranged in parallel, namely the roller shaft 8 and the roller shaft 2, wherein the cutting mechanism is arranged on the roller shaft 8, and the lining is arranged on the roller shaft 2. roller mechanism. The cutting mechanism includes a locking block 9, a knife seat 10, a pressing device 12 and a paper feed roller 13 which are sequentially sleeved on the roller shaft 8 from left to right, wherein the paper feed roller 13 is fixedly connected to the roller shaft 8, and the top The axial ends of the tightening device 12 respectively support the paper feed roller 13 and the knife holder 10, and the locking block 9 and the roller shaft 8 are adjustable and locked; The slope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com