A kind of double-loaded core-shell hydrogel and its preparation method and application

A hydrogel, dual-loading technology, applied in chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve the problems of complex treatment process, inability to degrade ammonia nitrogen, secondary pollution, etc., and achieve simple operation, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

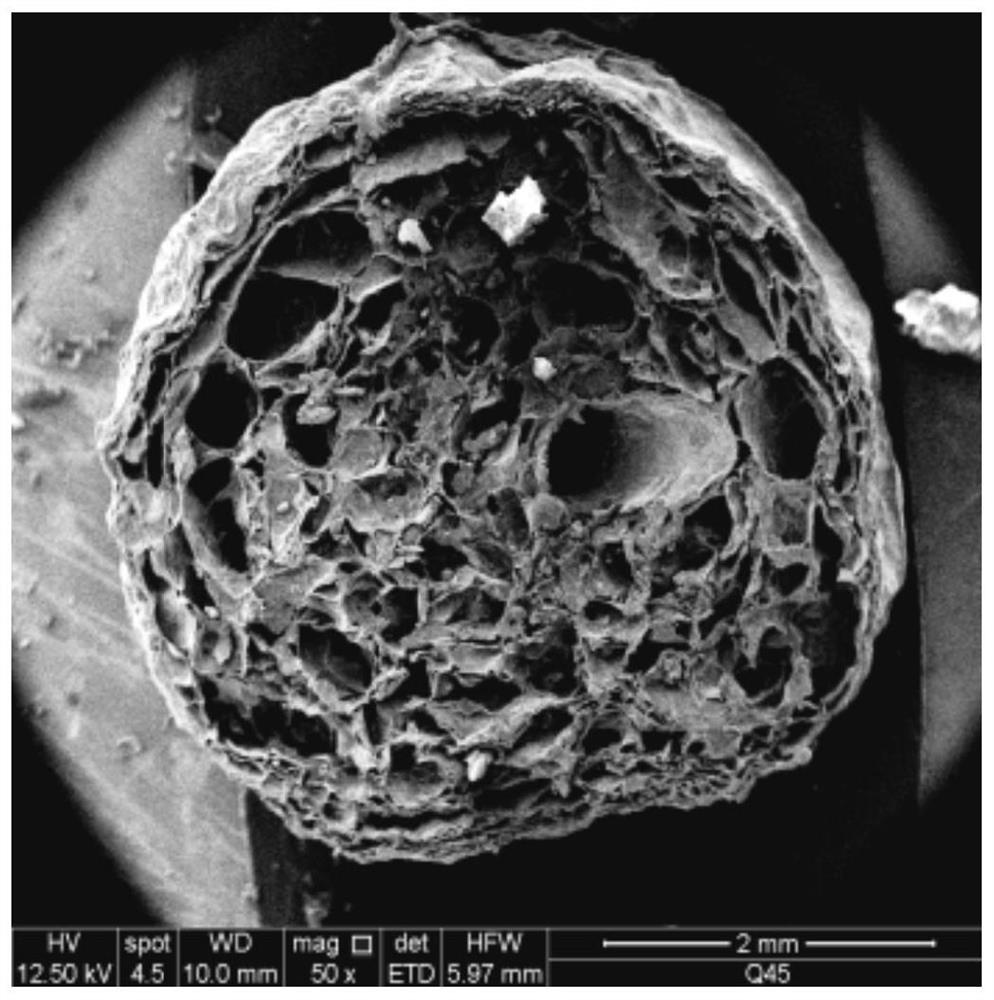

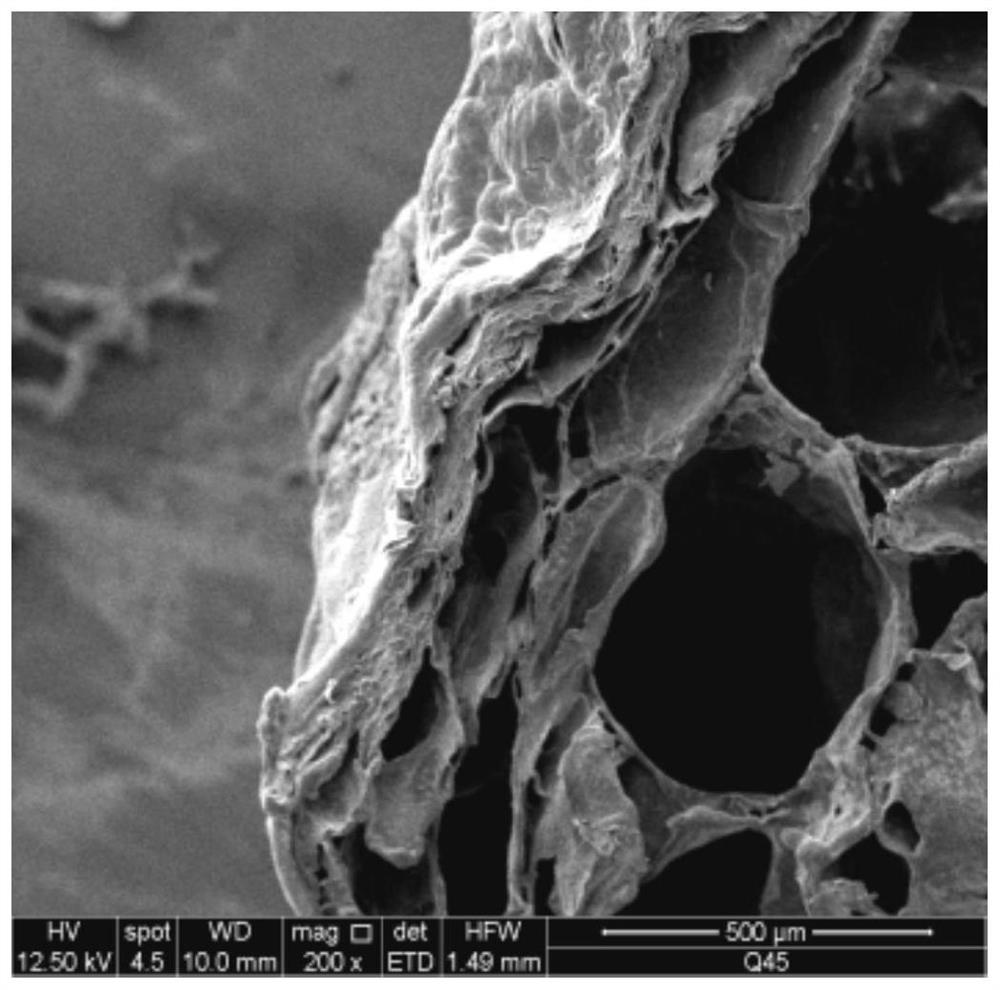

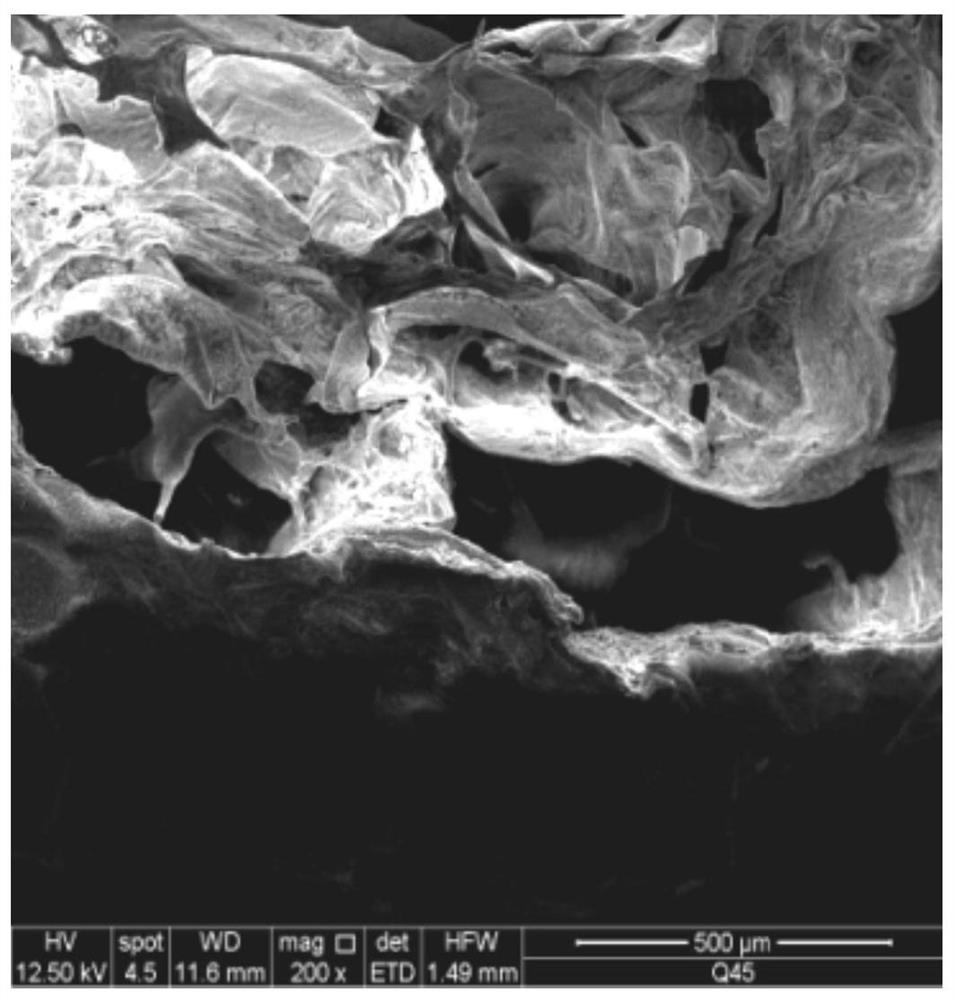

Image

Examples

preparation example Construction

[0030] The preparation method of a double-loaded core-shell hydrogel of the present invention uses natural polymers and synthetic polymers with adsorption functional groups as raw materials, and prepares double-loaded core-shell hydrogels through a step-by-step method, and natural polymers with adsorption functional groups Using hemicellulose, cellulose, hydroxypropyl cellulose, carboxymethyl cellulose, starch, hydroxyethyl cellulose, water-soluble chitin, sodium alginate, hyaluronic acid, lignosulfonate, agar, agar A mixture of one or more of sugar and collagen; polyacrylic acid is used for synthetic polymers;

[0031] Specific steps are as follows:

[0032] Step 1, preparation of the core matrix, mixing 5 to 10 parts by mass of natural polymers with adsorption functional groups and 1 to 5 parts of polyacrylic acid aqueous solution, stirring until the natural polymers with adsorption functional groups are completely dissolved; then adding mass The number of parts is 0.1-10 p...

Embodiment 1

[0041] A method for preparing a double-loaded core-shell hydrogel, comprising the following steps:

[0042] Step 1, add 0.1 parts of polyacrylic acid to 100 parts of deionized water in parts by mass, stir at 90°C for 2 hours to obtain matrix A, cool to room temperature for later use; add 5 parts by mass of hemicellulose to Add 100 parts of deionized water, stir at 50°C for 1 hour, until the hemicellulose is completely dissolved in deionized water to obtain matrix B, cool to room temperature for later use;

[0043] Step 2, mix 1 part of matrix A and 5 parts of matrix B in parts by mass, stir until completely mixed at a temperature of 65 ° C, and stir for 3 hours at a stirring speed of 100 r / min;

[0044] Then add 0.1 part of denitrifying bacteria, 0.01 part of nutrient solution and 0.05 part of buffer solution of citric acid-disodium hydrogen phosphate, stir and mix completely, the stirring speed is 100r / min, and the stirring time is 60min to obtain matrix C; wherein, The deni...

Embodiment 2

[0051] A method for preparing a double-loaded core-shell hydrogel, comprising the following steps:

[0052] Step 1, add 0.5 parts of polyacrylic acid into 100 parts of deionized water according to the number of parts by mass, and stir at 120°C for 1.5 hours to obtain matrix A, which is cooled to room temperature for later use; 1 part by mass of cellulose, 2 Add 100 parts of hemicellulose to 100 parts of deionized water, stir at 70°C for 0.5 hours until the cellulose and hemicellulose are completely dissolved in deionized water to obtain matrix B, cool to room temperature for later use;

[0053] Step 2, mix 5 parts by mass of matrix A and 10 parts of matrix B, stir until completely mixed at a temperature of 70°C, and stir for 2.5 hours at a stirring speed of 150r / min;

[0054] Then add 1 part of denitrifying bacteria, 1 part of nutrient solution and 0.02 part of tartaric acid-malic acid-sodium citrate buffer solution, stir and mix completely, the stirring speed is 150r / min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com