Integrated semi-nitrification-anaerobic ammonia oxidation reactor denitrification sewage treatment method

A technology of anaerobic ammonium oxidation and reactor, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water treatment parameter control, etc., can solve the problems of poor sludge flocculation performance, poor sludge flocculation performance, unfavorable sludge Aggregation to form biofilm and other problems, to achieve the effect of simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

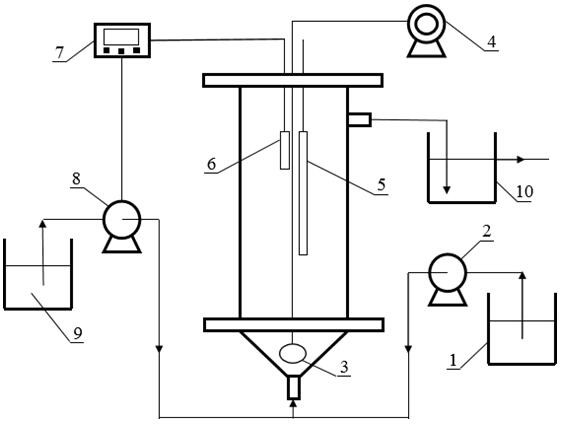

[0035] The integrated semi-nitrification-ANAMMOX system adopted in the present invention is as attached figure 1 As shown, it includes the water inlet tank, the reactor body, the sedimentation tank and the control system: the water inlet tank is connected to the water inlet at the bottom of the reactor body through a peristaltic pump; The aeration rate of the head is controlled by the aeration pump, and the middle and upper part is equipped with a pH online measuring instrument and a heating rod; the main body of the reactor is connected with the alkali tank, and the alkali is supplied to the reactor through the replenishment pump; the main body of the reactor is connected to the sedimentation tank through the water outlet. connect.

[0036] 1. Startup steps

[0037] First start the reactor, the inoculum of the SNAP reactor adopts the bacterial sludge enriched by the SNAP reactor cultivated in this laboratory and operated for more than one year, the MLSS is 10.1 g / L, the MLSS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com