Ammonia-nitrogen wastewater treatment agent and preparation method thereof

A technology of ammonia nitrogen wastewater and treatment agent, which is applied in animal husbandry wastewater treatment, water/sewage treatment, special compound water treatment, etc. It can solve the problem of increasing microbial treatment load and impact load, increased treatment cost and operating cost, and anaerobic effluent Solve the problems of high pollutant concentration and achieve the effect of improving ammonia nitrogen removal adsorption performance, high ion exchange performance, and increasing exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

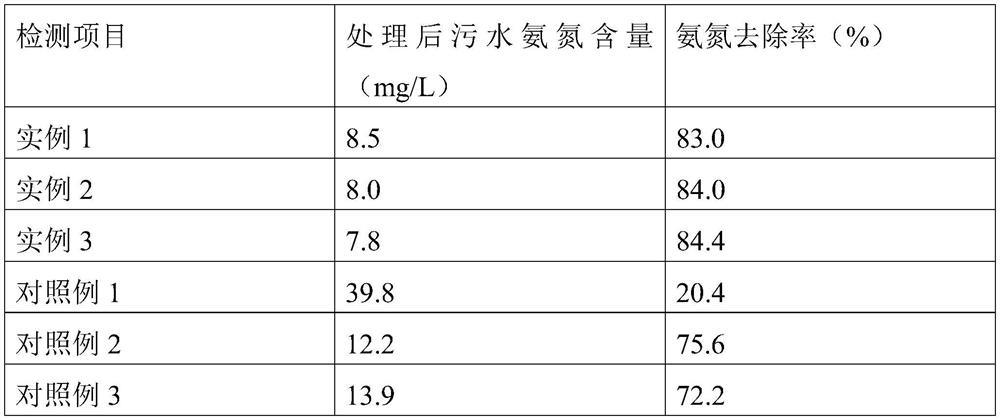

Examples

example 1

[0030] Weigh the zeolite particles, mix the zeolite particles and the dopamine solution with a mass fraction of 0.1% according to the mass ratio of 1:10, put them into the reactor, stir and react at a speed of 200r / min for 10h, and filter and separate to obtain the filter residue after the reaction;

[0031] The filter residue obtained above is mixed again with deionized water at a mass ratio of 1:15, stirred and dispersed to obtain a suspension and put into a reactor, and then a calcium chloride solution of 5% of the suspension mass is added to the reactor to 100r / min rotating speed stirring reaction 30min, after the stirring reaction is finished, filter and separate to obtain filter cake;

[0032]Then mix the filter cake obtained above and the sodium silicate solution with a mass fraction of 10% at a mass ratio of 1:8 and put it into the reactor, raise the temperature in the reactor to 40°C, and stir at a speed of 50r / min React for 1 hour, after the reaction is completed, fi...

example 2

[0037] Weigh the zeolite particles, mix the zeolite particles and the dopamine solution with a mass fraction of 0.1% according to the mass ratio of 1:10, put them into the reactor, stir and react at a speed of 250r / min for 11h, and filter and separate to obtain the filter residue after the reaction;

[0038] The filter residue obtained above is mixed again with deionized water at a mass ratio of 1:15, stirred and dispersed to obtain a suspension and put into a reactor, and then a calcium chloride solution of 5% of the suspension mass is added to the reactor to The rotating speed of 150r / min stirred and reacted for 35min, and after the stirred reaction was completed, the filter cake was obtained by filtration and separation;

[0039] Then mix the filter cake obtained above and the sodium silicate solution with a mass fraction of 10% at a mass ratio of 1:8 and put it into the reactor, raise the temperature in the reactor to 45°C, and stir at a speed of 55r / min After reacting for...

example 3

[0044] Weigh the zeolite particles, mix the zeolite particles and the dopamine solution with a mass fraction of 0.1% according to the mass ratio of 1:10, put them into the reactor, stir and react at a speed of 300r / min for 12h, and filter and separate to obtain the filter residue after the reaction;

[0045] The filter residue obtained above is mixed again with deionized water at a mass ratio of 1:15, stirred and dispersed to obtain a suspension and put into a reactor, and then a calcium chloride solution of 5% of the suspension mass is added to the reactor to The rotating speed of 200r / min stirred and reacted for 40min, and after the stirring and reacted, the filter cake was obtained by filtration and separation;

[0046] Then mix the filter cake obtained above and the sodium silicate solution with a mass fraction of 10% at a mass ratio of 1:8 and put it into the reactor, raise the temperature in the reactor to 50°C, and stir at a speed of 60r / min React for 2 hours, after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com