Comprehensive safety protection system for automatic driving of coke oven electric locomotive

A safety protection and automatic driving technology, which is applied in furnace safety devices, coke ovens, petroleum industry, etc., can solve problems such as lack of effective protection, coke tank lifting and decoupling, human and object intrusion, etc., to achieve improved operation safety, The effect of reducing poor operating conditions and increasing the automatic operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

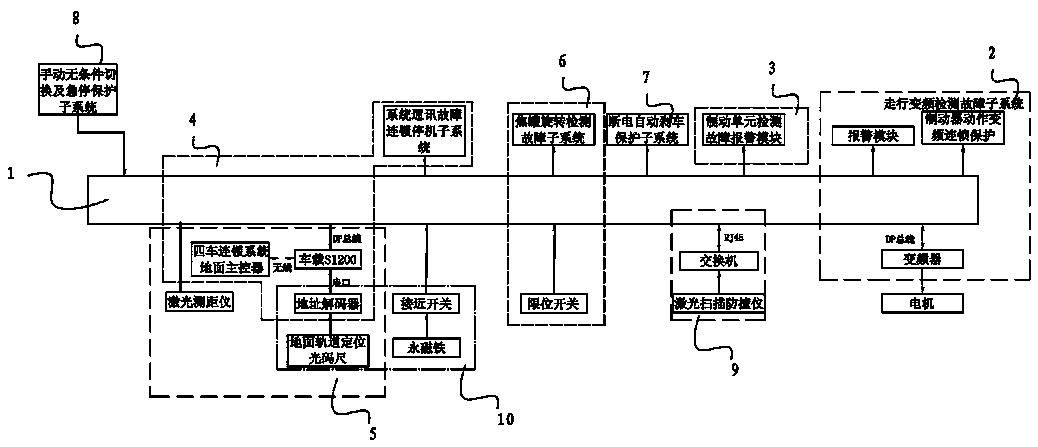

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

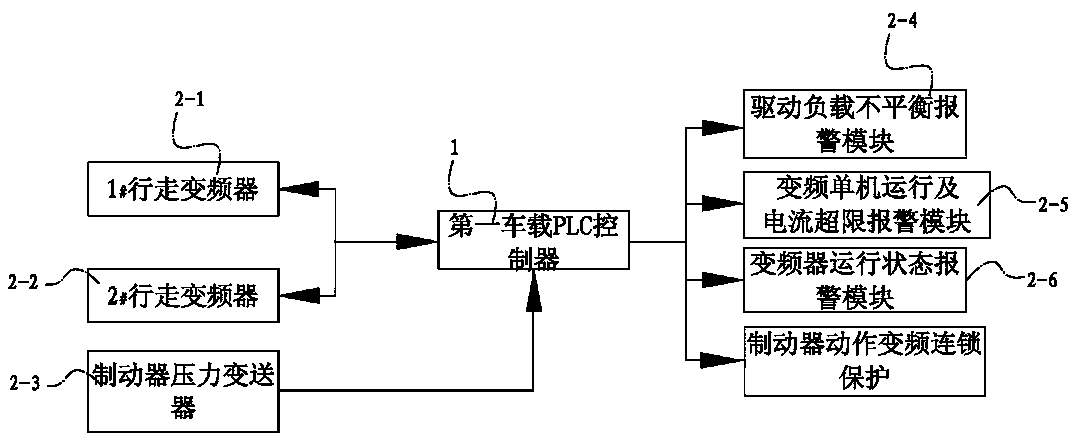

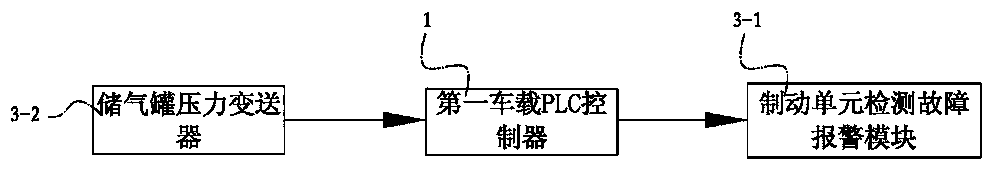

[0033] figure 1 The coke oven electric locomotive automatic driving comprehensive safety protection system shown includes a first vehicle-mounted PLC controller 1, the first vehicle-mounted PLC controller 1 is connected with a power-off automatic braking protection subsystem 7, a brake detection fault subsystem 3, a laser Scanning anti-collision safety protection subsystem 9, forced downshift detection and protection subsystem 10, coke tank rotation detection fault subsystem 6, running frequency conversion detection fault subsystem 2, system communication detection fault subsystem 4, address detection and protection subsystem 5 and Manual unconditional switching and emergency stop protection subsystem 8 connection.

[0034] Power failure automatic braking protection subsystem 7, such as Figure 7 As shown, it includes a vehicle power-off fault detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com