Material demand weighted prediction method based on enterprise MRP

A technology of weighted forecasting and material demand, applied in marketing and other directions, can solve problems such as high inventory level, inability to optimize algorithms, and no consideration of enterprise manpower and production capacity, so as to reduce costs, improve defects, and avoid excessive differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

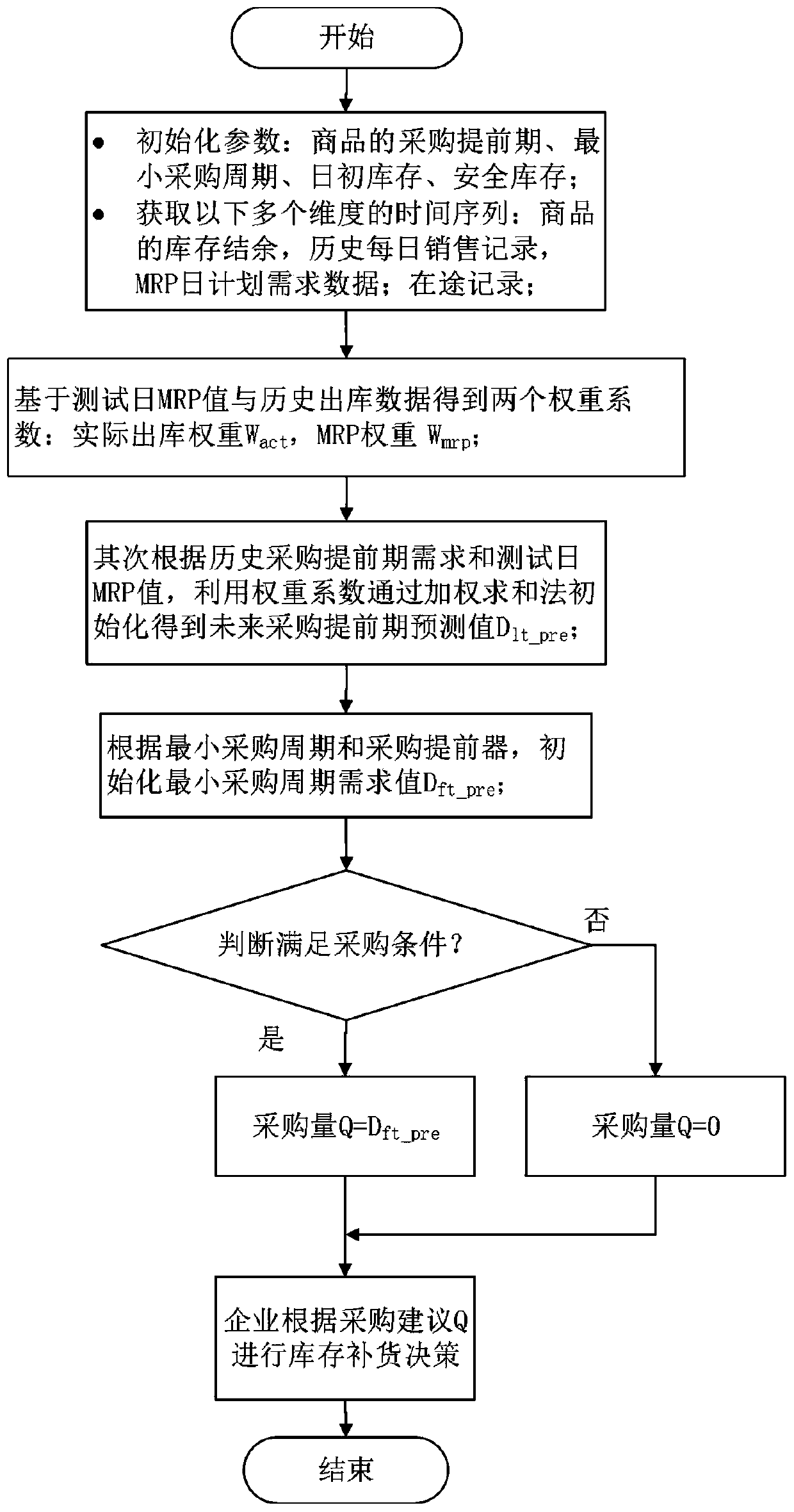

[0030] In order to make the object and effect of the present invention clearer, the method of the present invention will be described in detail below.

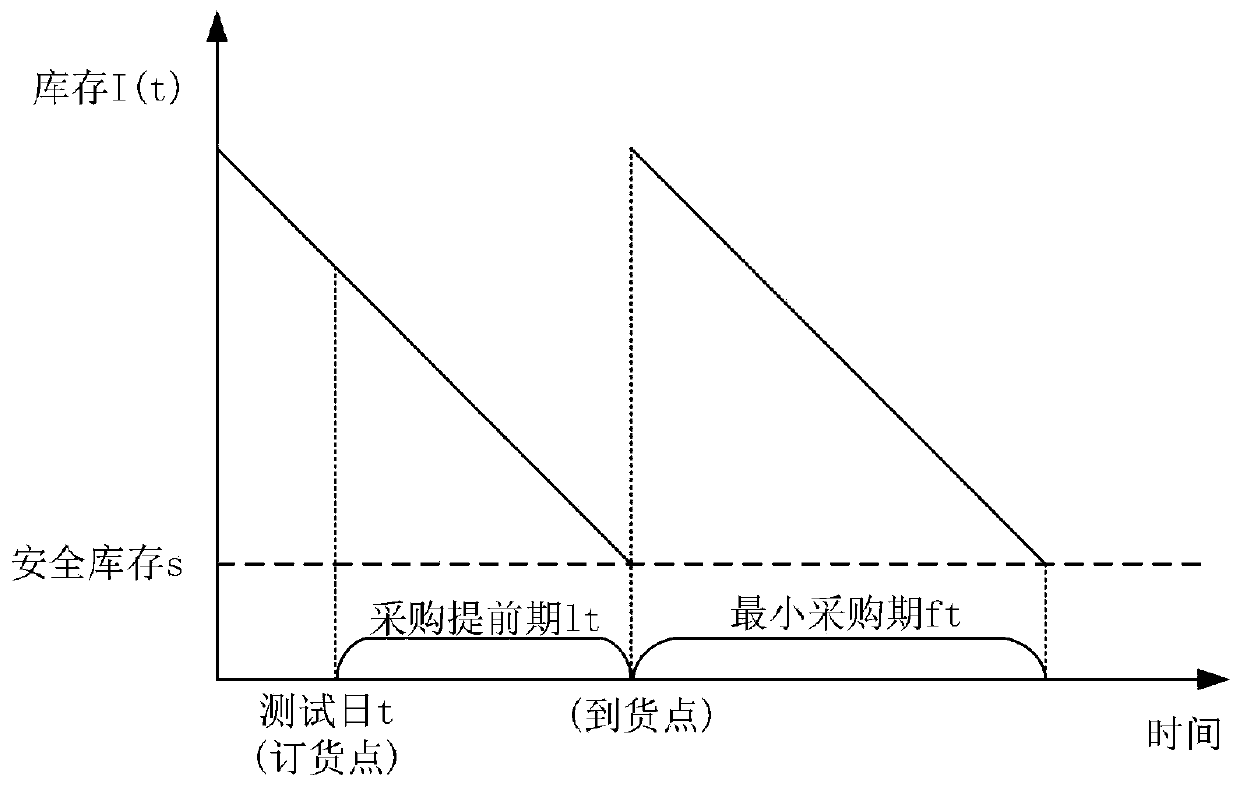

[0031] The structural model of a general storage system can be expressed as figure 1 form. Due to the demand of production or sales, a certain amount of stock goods is taken out from the storage point, which is the output of the storage system. And when the continuous output of stored goods leads to the continuous reduction of the quantity in the warehouse, the enterprise must take appropriate replenishment behaviors in time, which is the input of the storage system. As for the demand in the system, the mode of demand can be uniform continuous or intermittent batch, and the quantity of demand can be deterministic or random. Replenishment can be in the form of business units ordering from outside or arranging production activities by themselves. The main quantitative indicators for researching replenishment are: determining ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com