Vertical lifting goods collecting mechanism of vending machine

A vertical lift, vending machine technology, applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. and other problems, to achieve the effect of simple structure, increased stability, and easy pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the specific embodiments of the present invention to facilitate those skilled in the art to understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments, for those of ordinary skill in the art, as long as various changes These changes are obvious within the spirit and scope of the present invention defined and determined by the appended claims, and all inventions and creations using the concept of the present invention are protected.

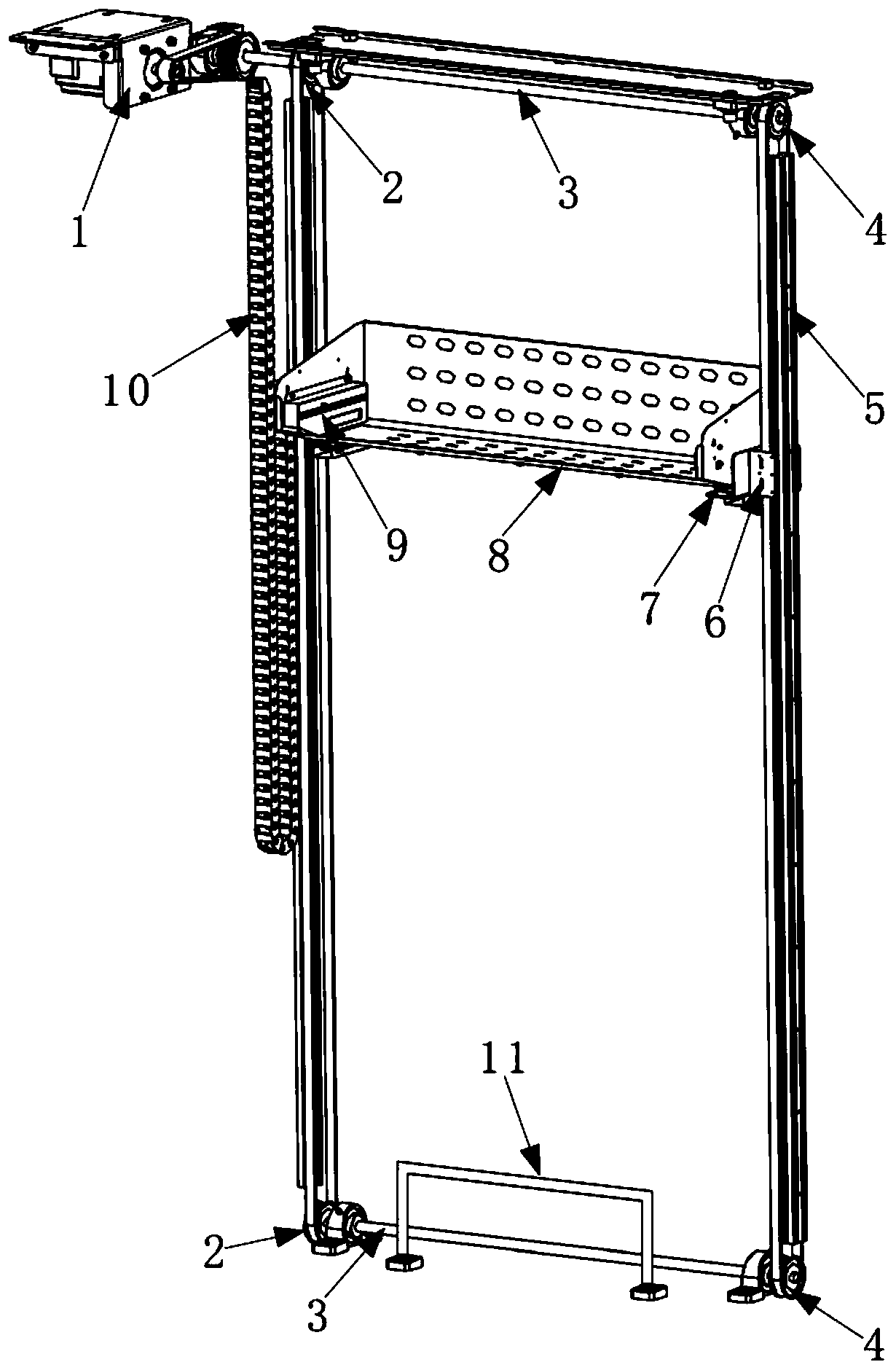

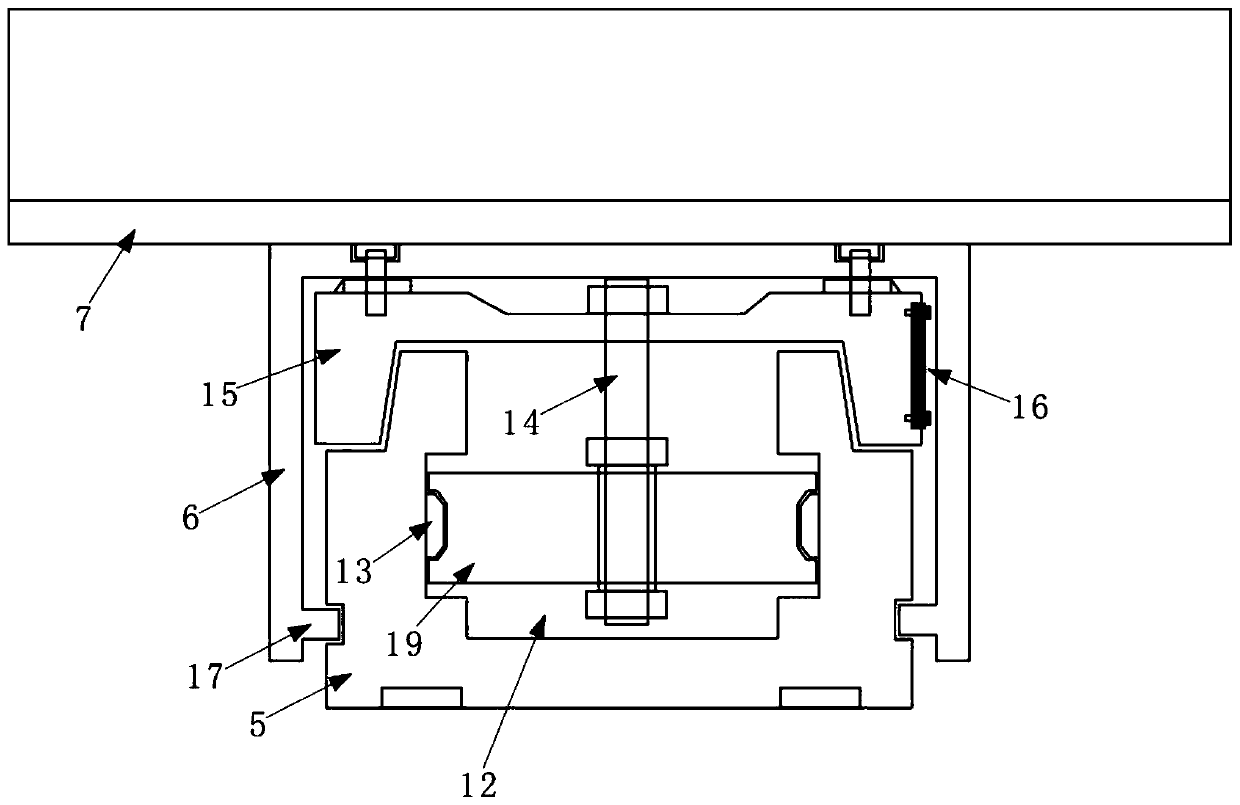

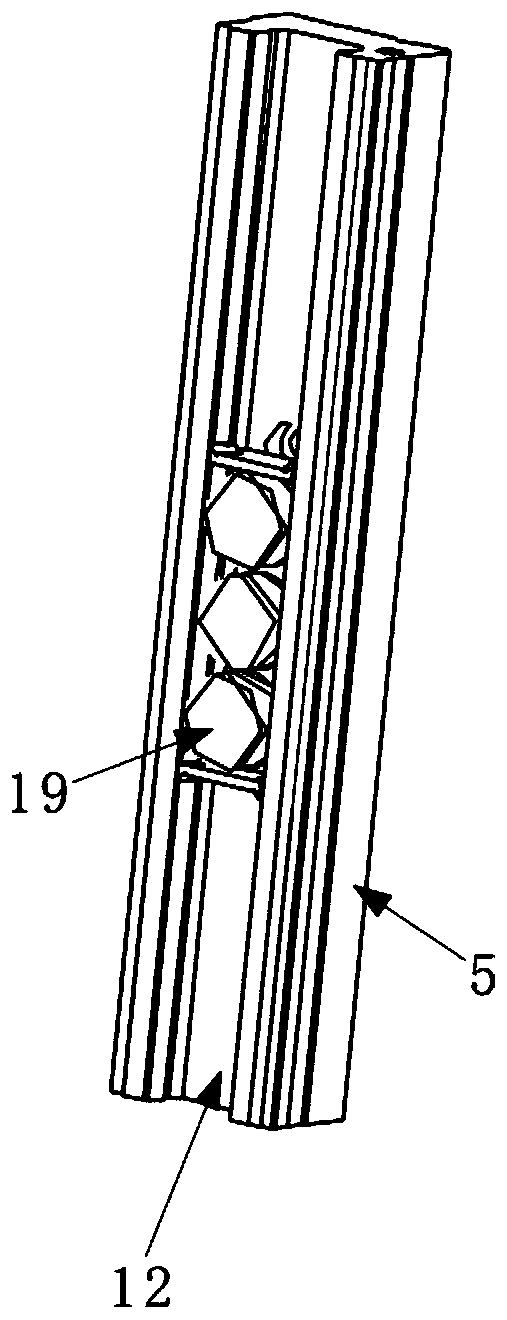

[0023] Such as figure 1 with figure 2 As shown, the vertical lifting and retrieval mechanism of the vending machine includes two vertically arranged sliding rails 5, both of which are fixed on the casing of the vending machine, and a pickup slot 8 is provided between the two sliding rails 5 ; Two sliding rails 5 are provided with a sliding groove 12, the side wall of the sliding groove 12 is provided with a groove, and a pulley 19 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com