Square lithium-ion battery automatic liquid injection tool

A lithium-ion battery, automatic technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of electrolyte infiltration difficulty, square shell expansion, poor liquid injection effect, etc., to solve manual liquid injection Difficult, anti-corrosion, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

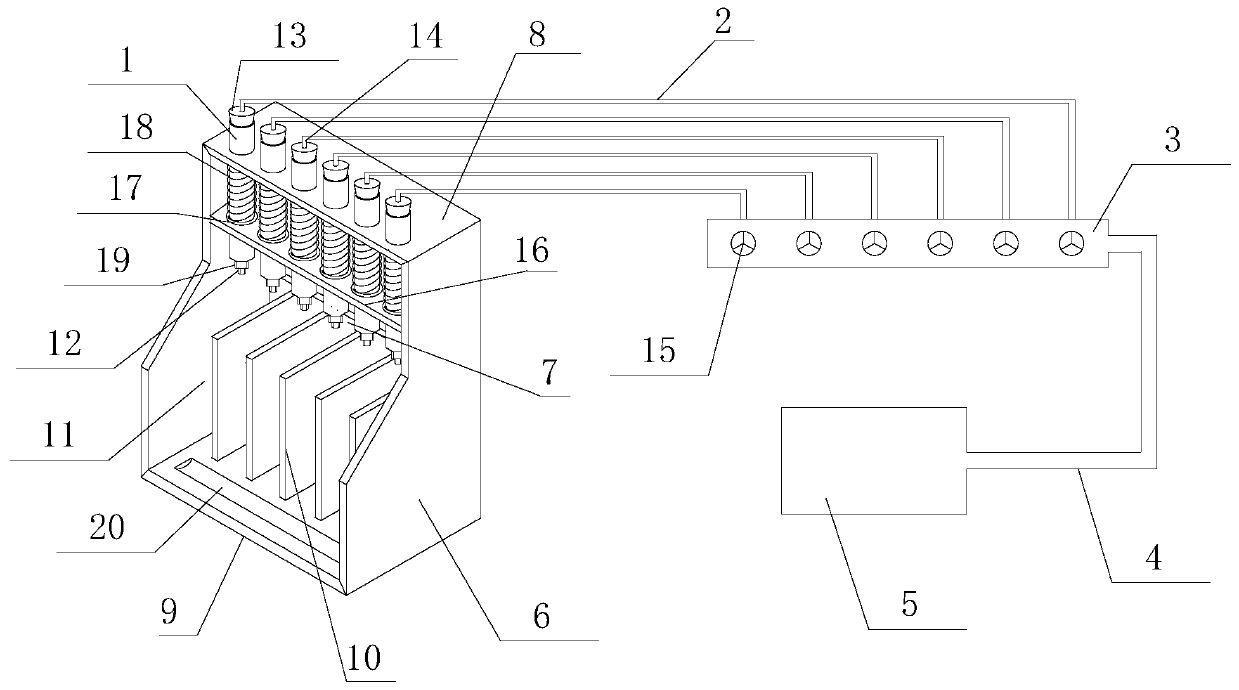

[0016] refer to figure 1 , the present invention proposes a square lithium-ion battery automatic liquid injection tool, including a support frame, a plurality of liquid injection measuring cylinders 1, a plurality of branch exhaust pipes 2, a manifold 3, a main flow exhaust pipe 4 and a vacuum pump 5, wherein:

[0017] The support frame includes two side panels 6 , a rear panel 7 , a top panel 8 , a bottom panel 9 and a plurality of partition panels 10 . The two side plates 6 are arranged vertically opposite each other, the rear plate 7 is arranged vertically, and the two ends of the rear plate 7 are respectively connected with the two side plates 6 . The top plate 8 is arranged horizontally and the two ends of the top plate 8 are connected to the two side plates 6 respectively. The bottom plate 9 is located below the top plate 8 and parallel to the top plate 8. A plurality of separators 10 are located between the two side plates 6 and the separators 10 are parallel to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com